General Variable Frequency Drive

Brief Introduction

The general variable frequency drive (VFD) is the electrical control equipment utilizing the frequency conversion technology and microelectronic technology to control the AC motor via changing the frequency of working power of motor. It is basically composed of rectifier (AC to DC), smoothing unit, inverter (DC to AC), brake unit, driving unit, detecting unit, microprocessing unit, etc.

The equipment adjusts the voltage and frequency of the output power via the breaking of internal IGBT (insulated gate bipolar transistor), and provides the required power supply voltage accoridng to the actual need of motor, thus reaching the purpose of energy saving and speed adjusting. In addition, the general VFD has many protection functions such as overcurrent protection, overvoltage protection, overload protection, etc. With the continuous improvement of industrial automation, it has a very wide range of application.

Functions and Features

1. The product adopts the SVC current vector control mode, and is optional with V/F control mode.

2. It is configured flexibly with multi-node setting for V/F curve.

3. The equipment is also avilable with motor parameters static self-turning function.

4. It is outfitted with the multifunctional programmable input port, allowing for programming relay output.

5. The general variable frequency drive is built with PID regulator internally which is conveniently for customers to carry out simple closed loop control involving flow, pressure, etc.

6. The overcurrent and overvoltage monitoring protection can protect the product and the equipment of customers to the fullest extent.

7. The product takes advantages of the unique adaptive control technology and pulse width modulation technology to obtain the optimum control performance.

8. Designed with compact structure and small volume, it has dependable peformance.

9. The product adapts to the large range wide power grid change design, especially the special occasions with low voltage.

Application

The general variable frequency drive is alrgely applied into the fields concerning machinery, textile, printing and dyeing, packaging, printing, ceramics, pharmacy, food, production line, etc.

Specification

| Item | Standard specification | |

| Input | Input voltage | Single phase 220V, three-phase 380V, 50Hz/60Hz |

| Allowable variable value | Voltage: -20% ~ 20% Voltage unbalance rate: <3% | |

| Output | Rated voltage | 0 ~ 220V/0 ~ 380V |

| Frequency range | 0Hz ~ 400Hz | |

| Motor | Applicable motor power | 0.4kW ~ 630kW (0.5HP ~ 840HP) |

| Control function | Modulation mode | Optimizing space voltage vector PWM |

| Control mode | Sensorless vector control | |

| Frequency accuracy | Digital setting: Maximum frequency × ±0. 01 Analog setting: Maximum frequency × ±0.2% | |

| Frequency resolution | Digital setting: 0.01Hz Analog setting: Maximum frequency × 0.1% | |

| Torque boost | Automatic torque boost, manual torque boost 1%~30.0% (V/F Mode) | |

| V/F curve | Linear V/F curve, square V/F curve, User defined V/F curve | |

| Built-in PID | It facilitates forming closed loop control system, and is suitable for pressure and flow control. | |

| Multi-speed operation | Achieving multi-speed operation via built-in PLC or control terminal | |

| Sensorless vector control | Torque characteristic | Outputting 150% rated torque at 1Hz, rotating speed stabilization accuracy of 0.1% |

| Motor parameter automatic reading | Indentifying motor parameters automatically in the case of the motor stopping running completely to get optimum control effect | |

| Running function | Running command channel | Presetting via operating panel, presetting via control terminal, presetting via serial port (The three ways can be switched.) |

| Frequency setting channel | Presetting via keyboard potentiometer, presetting via ▲ and ▼ keys on the keyboard, presetting via functional code digits, presetting via serial port. Presetting via terminal UP/DOWN, presetting via analog signal, presetting via combination | |

| Switch input channel | Forward and reverse rotating command, 6-way programmable switching value input to set at most 30 kinds of functions | |

| Analog input channel | 2-way analog signal input optional with 0 to 20mA and 0 to 10V | |

| Analog output channel | Analog signal output optional with 0 to 10V and 0 to 20mA | |

| Switching value output channel | 3-way programmable open collector output, 1-way relay output signal | |

| Operating panel | LED digital display | Displaying preset frequency, output voltage, output current, etc. |

| Protection function | Overcurrent protection, overvoltage protection, undervoltage protection, overheating protection, overload protection, etc. | |

Related Names

Frequency Converter Supplier | Frequency Motor Control | Industrial Control Device

Links:https://www.globefindpro.com/products/85660.html

-

Electrical Specialized Power Inverter

Electrical Specialized Power Inverter

-

AC Energy Saving Lamps

AC Energy Saving Lamps

-

High Frequency Rack-mounted Online UPS

High Frequency Rack-mounted Online UPS

-

LED Flood Light/Spot Light/Tunnel Light

LED Flood Light/Spot Light/Tunnel Light

-

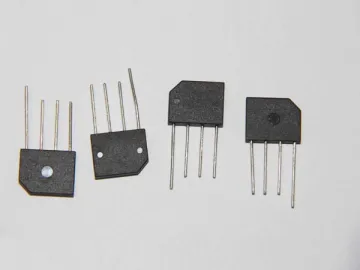

YZPST-3 Bridge Rectifier

YZPST-3 Bridge Rectifier

-

Single Phase Full-Automatic Compensated Voltage Stabilizer

Single Phase Full-Automatic Compensated Voltage Stabilizer

-

Digital Single/Three Phase Servo Voltage Stabilizer

Digital Single/Three Phase Servo Voltage Stabilizer

-

Socket Type Relay Control Single Phase Voltage Stabilizer

Socket Type Relay Control Single Phase Voltage Stabilizer

-

Low Frequency Power Inverter with Charger

Low Frequency Power Inverter with Charger

-

PV Combiner Box

PV Combiner Box

-

DC Energy Saving Lamps

DC Energy Saving Lamps

-

Solar Street Lighting System

Solar Street Lighting System