Vector Control Variable Frequency Drive

Product Features

1.This vector control variable frequency drive utilizes advanced SVC vector control and V/F control.

2. In the specifications of 0.75kW to 18.5kW, the product is internally mounted with the brake device in the standard configuration. It supports direct connection with the braking resistor if rapid stop is in need. As for the 160kW and above products, the direct current reactor is equipped in standard configuration to increase the output power factor, eliminating the impact of the high harmonic to the product and reducing the interference to the surroundings.

3. Our vector control variable frequency drive is configured internally with various devices, including the automatic torque compensation system, efficient rotating speed compensation system, PID adjustor and the RS-485 communication port supporting the MODBUS communication protocol.

4. It is able to restart the rotary motor smoothly without any impact by means of torque tracking.

5. This product supports online monitoring and adjustment on multiple parameters.

6. With affluent, flexible input and output interfaces and multiple controls, the product can be combined with diversified equipment in the operation, such as PLC, industrial personal computer or instrument.

7. The LED and LCD operating panels can be selected to accomplish convenient and rapid operation.

8. This vector control variable frequency drive offers pulse input and output, facilitating the digital control in closed loop.

9. It is capable of running at the energy saving mode. Compared with the V/F control system at the same working frequency, this product uses lower current. Moreover, the working voltage can be automatically adjusted, too. If the voltage of the electrical grid starts to change sometime, this product is able to keep the constant output voltage automatically.

10. Designed with totally separated air ductwork, our product offers an optimal dustproof working environment. Additionally, all the plates are plated with conformal coating, presenting perfect protection to the product.

Application

This vector control variable frequency drive is commonly applied in machinery industry about plastics, ceramic, electrics, textile, light industry, pharmaceuticals, packing, printing and dyeing industry, escalator, wire and cable, lathe and grinding machine, bag making, cold rolling machine, low frequency roller table, centrifugal machine, paper making and chemical fiber production lines. As the direct replacement of the AC torque motor, it can be used for controlling the general unwinding or rewinding with constant tension.

Technical Parameters

| PR6100 Series (0.4kW~630kW) | Specifications | |

| Input | Rated voltage and frequency | Single-phase 220V, three-phase 220V, |

| Three-phase 380V; 50Hz/60Hz | ||

| Variable allowable value | Voltage: -20% ~ 20% | |

| Voltage unbalance: <3% Frequency: ±5% | ||

| Output | Rated voltage | 0~200V /0~380V |

| Frequency range | 0Hz~400Hz | |

| Overload capability | 150% for 1 min, 180% for 1s, 200% instant protection | |

| Main control function | Control mode | Space voltage vector PWM control, sensorless vector control (SVC) |

| Frequency accuracy | Digital setting: Max frequency ×±0. 01% Analog setting: Max frequency ×±0. 2% | |

| Frequency resolution | Digital setting: 0.01Hz | |

| Analog setting: Max frequency ×0.1% | ||

| Torque rise | Auto torque rise, manual torque rise 1%~30.0% | |

| V/F curve | Three ways: linear V/F curve, square V/F curve, user self-defining V/F curve | |

| Acceleration/deceleration curve | Optional time unit (Min/s), the longest: 6000s (settable in the range of 0.1~3600s). | |

| DC braking | Be optional during both starting and stopping, the operating frequency: 0~ 20Hz, operating voltage level: 0~20%, operating time: settable within 0~20s | |

| Jogging | Jogging frequency range: 0.1Hz~50.00Hz, jogging acceleration and deceleration time: 0.1~3600s. | |

| Built-in PID | It is convenient for forming closed loop control system, applicable for course control like pressure and flow, etc. | |

| Multispeed operating | Realize multispeed running by built-in PLC or control terminal. | |

| Weaving wobble frequency | Can get wobble frequency of adjustable central frequency | |

| Automatic voltage adjustment | When main voltage changes, the output voltage may be kept constant by adjusting PWM output (AVR function). | |

| Automatic energy saving operation | According to load conditions, V/F curve can be optimized automatically to realize energy saving operation. | |

| Automatic current limiting | Limit in-service current automatically so as to avoid tripping for fault caused by frequent over current. | |

| Sensorless vector control | Torsion characteristic | 150% output of torque at 1Hz, rotating accuracy: 0.1% |

| Motor parameters (automatic reading) | Read the parameters from then motor when the motor stops completely in order to achieve optimal controlling effect. | |

| Running function | Running command channel | Presetting via operating manual, Presetting via control terminal, presetting via serial port, switching by three ways. |

| Frequency setting channel | Presetting via keyboard analog potentiometer, setting of keyboard ▲, ▼ keys, presetting via functional code digits, presetting via serial port, presetting via terminal UP/DOWN, presetting via analog voltage, presetting via analog current, presetting via impulse, presetting via combination, switching at any time by kinds of setting ways. | |

| Switch input channel | Forward/reverse rotating command, 6-way programmable switching value input to set 30 functions. | |

| Analog input channel | 2-way analog signal input, 0~20mA, 0~10V optional. | |

| Analog output channel | Analog signal output 0~10V, 0~20mA to get output of physical quantity like frequency and output frequency | |

| Switch output channel | 3-way programmable open collector output, 1-way relay output signal, different physical parameters output. | |

| Operating panel | LED display | Display setting frequency, output voltage, output current and so on. |

| External display instrument | Display output frequency, output current, output voltage and so on. | |

| Protection function | Over current protection, over voltage protection, low voltage protection, overheat protection, overload protection. | |

| Option | Braking unit, remote operating panel, remote cable, soleplate of keyboard. | |

| Environment | Service location | Indoors, away from sun, dust, corrosive gas, oil fog, steam and so on. |

| Altitude | Lower than 1000m (derating at higher altitude of more than 1000m) | |

| Temperature | -10℃~ 40℃ | |

| Humidity | Less than 90%RH, no condensation | |

| Vibration | Less than 5.9m/s2 (0.6m) | |

| Storage temperature | -20℃~ 60℃ | |

| Structure | Ingress protection | IP20 (In service state or keyboard state) |

| Cooling way | Air blast cooling | |

Related Names

Frequency Changer | Industrial Motor Control Solution | VFD Distributors

Links:https://www.globefindpro.com/products/85675.html

-

C2 Cement Fixed Resistors

C2 Cement Fixed Resistors

-

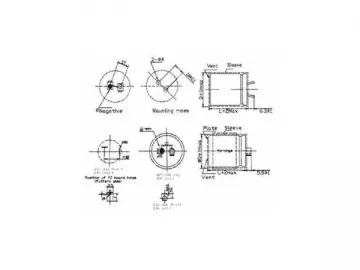

Bobbin

Bobbin

-

High Frequency In-car Pure Sine Wave Power Inverter with/without Charger

High Frequency In-car Pure Sine Wave Power Inverter with/without Charger

-

LCD Single/Three Phase Servo Voltage Stabilizer

LCD Single/Three Phase Servo Voltage Stabilizer

-

Three Phase Split Phase Regulating Full-Automatic Compensated Voltage Stabilizer

Three Phase Split Phase Regulating Full-Automatic Compensated Voltage Stabilizer

-

E14 Electrolytic Capacitor

E14 Electrolytic Capacitor

-

DC Solar Power System

DC Solar Power System

-

Three Phase Full-Automatic Compensated Voltage Stabilizer

Three Phase Full-Automatic Compensated Voltage Stabilizer

-

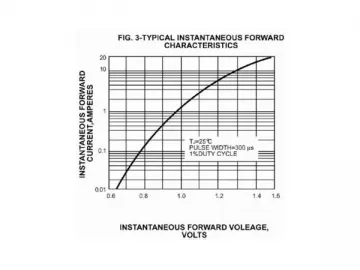

10A-2 Schottky Diode

10A-2 Schottky Diode

-

Surface Mount Rectifier Diode

Surface Mount Rectifier Diode

-

Single Phase Full-Automatic Compensated Voltage Stabilizer

Single Phase Full-Automatic Compensated Voltage Stabilizer

-

YZPST-3 Bridge Rectifier

YZPST-3 Bridge Rectifier