Special Polyphenylene Sulfide (PPS)

After being carefully chosen, PPS raw materials are melted and cooled down to form a reliable PPS cast film. PPS cast film has numerous beneficial properties such as heat resistance, flame retardance, minimal water absorption, insulation, and anti-corrosion.

FeaturesExcellent bonding force with glass/carbon fiber: Special PPS raw material with high performance is selected to improve the bonding force with glass fiber/carbon fiber;

Great resistance to corrosion: providing protection against most corrosive agents such as acids, alkalis, salts and organic solvents.

Excellent uniformity: small thickness fluctuation to meet the performance uniformity requirements of customers for thin film applications;

Impressive temperature resistance: long-term service temperatures up to 180℃ and short-term temperatures as high as 230℃. Basic properties

| Grade | Item | Unit | Index |

| MC1120 | Avg. thickness | μm | 120±3 |

| Width | mm | 1205±5 | |

| Tensile strength | Mpa | 40-65 | |

| MC1060 | Avg. thickness | μm | 60±3 |

| Width | mm | 1205±5 | |

| Tensile strength | Mpa | 40-65 |

Thermal conductive PPS tube

PPS thermal conductive pipe is a type of special composite material consisting of a variety of additives added to a high-performing PPS substrate resin. The PPS heat pipe is lightweight and highly heat resistant. It also has superior corrosion resistance and mechanical properties. In addition, PPS thermal conductive pipe features a smooth inner and outer surface and a uniform, controllable diameter.

Excellent thermal conductivity: the comprehensive thermal conductivity as high as 4 W/ (m * K);

Outstanding protection against corrosion: able to withstand most chemical elements like acids, alkalis, salts and organic solvents;

Temperature resistance: long-term service temperatures up to 180℃ and short-term temperatures as high as 230℃. Recyclable and reusable. Basic properties

| Grade | Item | Unit | Index |

| 19/15 | Outer diameter | mm | 19±0.2 |

| Inner diameter | mm | 1200±20 | |

| Length | m | ≤10 | |

| Hydraulic burst pressure | MPa | >1.5 | |

| 25/20 | Outer diameter | mm | 25±0.2 |

| Inner diameter | mm | 20±0.2 | |

| Length | m | ≤10 | |

| Hydraulic burst pressure | MPa | >1.5 |

PPS Monofilament

PPS monofilament is manufactured via melt extrusion, drawing, and thermo-forming techniques. Products can be customized in terms of filament diameter and mechanical properties, tailored to meet the specific requirements of customers.

FeaturesUniformity filament diameter: a minor variance in diameter, providing superior accuracy when filtering;

Excellent mechanical properties: the tensile strength and toughness of PPS monofilament can be adjusted according to customer requirements;

Outstanding heat-tolerance: long-term service temperatures up to 170℃ and short-term temperatures as high as 200℃. Basic properties

| Grade | Item | Unit | Index |

| 0.20mm | Filament diameter | mm | 0.20±0.007 |

| Tensile strength | cN/dtex | ≥3.85 | |

| Elongation at break | % | 20-35 | |

| 0.30mm | Filament diameter | mm | 0.30±0.01 |

| Tensile strength | cN/dtex | ≥3.35 | |

| Elongation at break | % | 20-35 | |

| 0.50mm | Filament diameter | mm | 0.50±0.01 |

| Tensile strength | cN/dtex | ≥3.05 | |

| Elongation at break | % | 25-40 | |

| 0.90mm | Filament diameter | mm | 0.90±0.02 |

| Tensile strength | cN/dtex | ≥2.70 | |

| Elongation at break | % | 25-40 |

Links:https://www.globefindpro.com/products/857.html

-

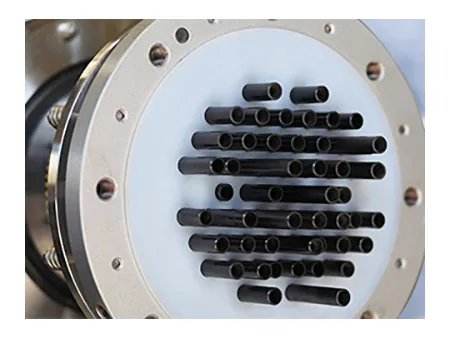

Tips for Cleaning Silicon Carbide Heat Exchanger

Tips for Cleaning Silicon Carbide Heat Exchanger

-

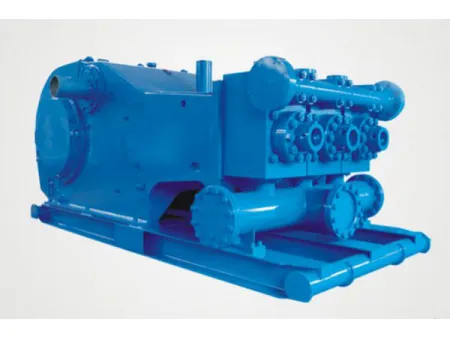

Mud Pumps

Mud Pumps

-

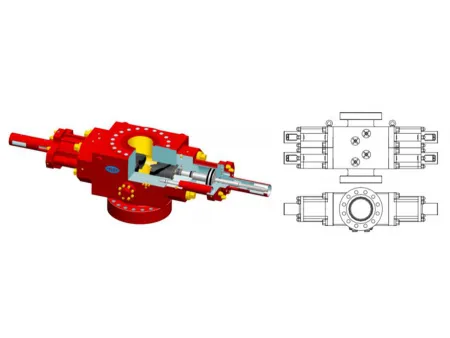

Choke Manifold

Choke Manifold

-

Rotary BOP (Blowout Preventer)

Rotary BOP (Blowout Preventer)

-

Daily Maintenance of Glass Lined Reactor

Daily Maintenance of Glass Lined Reactor

-

Ram BOP

Ram BOP

-

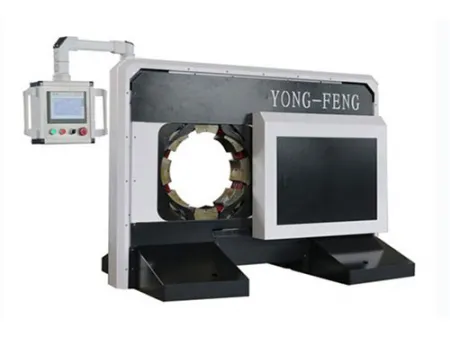

YONG-FENG Y630 Hose/Pipe Crimping Machine

YONG-FENG Y630 Hose/Pipe Crimping Machine

-

High Pressure Flexible Composite Hoses

High Pressure Flexible Composite Hoses

-

BOP Spare Parts

BOP Spare Parts

-

YONG-FENG Y360 Hose/Pipe Crimping Machine

YONG-FENG Y360 Hose/Pipe Crimping Machine

-

Kill Manifold

Kill Manifold

-

Choke and Kill Hoses

Choke and Kill Hoses