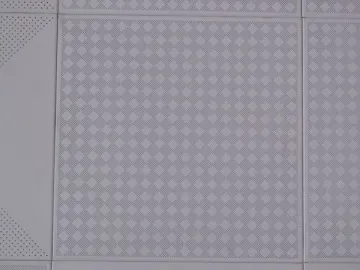

Aluminum Ceiling Tiles

Our aluminum ceiling tiles are well received by customers, due to their excellent quality, novel and beautiful appearance design, as well as easy installation.

As one of our most popular styles of drop ceiling panels, our aluminum ceiling tiles adopt high quality aluminum-magnesium alloy panel as the substrate. It is a kind of aluminum panel undergoing processes such as degreasing and chemical treatment, roller coating of imported PVDF coating, as well as drying and curing. The aluminum ceiling panel not only enjoys good strength and superior flexibility of the aluminum plate, but also has good corrosion resistance and weathering resistance of the film.

In addition, our aluminum ceiling tile has a complete range of types, including the aluminum veneer ceiling, aluminum honeycomb ceiling, standard square plate ceiling, suspended ceiling, C-type strip ceiling, U-type strip combination ceiling, D-type strip ceiling, aluminum strip ceiling, round pipe ceiling, square pipe ceiling, perforated ceiling, etc.

Our aluminum ceiling tiles effectively overcome the shortcomings of traditional gypsum board and mineral wool board products, such as single type, not easy to scrub, exposed frame and keel installation. It also overcomes the defects and limitations of PVC suspended ceiling panels, like poor oxidation resistance, non- moistureproof, non-fireproof, easy deformation and discoloration, and often for old-fashioned common home decoration. Therefore, with people’s higher requirements on decoration quality, our range of aluminum ceiling tiles has become the most popular style of decorative ceiling tiles which are basically used to make ceiling in home decoration.

In the processing technology, our aluminum ceiling tiles adopt drying and curing after roll coating, which is different from the common dip coating chemical treatment. This effectively controls the coating quality, and eliminates the defects such as dead angle that is easily to be produced in coating. In addition, it also reduces pollution to the environment, and meets the environmental requirements of developed countries.

The colorful roller painted aluminum ceiling tiles can not only withstand high wind and high pressure deformation, but also allows arbitrary cutting, slitting, punching, notching, drilling, arc bending and compression molding. They are widely used in the construction industry, such as industrial plants, office buildings, shopping malls, railway stations, subway, airport buildings, modern large hangar, large gymnasium, large clubs, home decoration, etc.

The aluminum gusset plate is available in many specifications, including the width and thickness of panel, and the height of edge folded. The surface can be perforated or flat. The perforated type aluminum ceiling tile allows ventilation and sound-absorbing. With an internal layer of cushion film, moisture can be absorbed by the film through the punched hole. Hence, this type is best for use in the kitchen where a large amount of moisture is contained. 600mm×600mm tiny hole square plate, C150/C100 strip plate, and 300 × 300, 300 × 600 aluminum plate are the most widely used.

The quality of aluminum gusset plate depends on the texture of aluminum material. The plate used in general engineering comes with a thickness of 0.8 mm or higher. As some engineering gusset plates are very long, so the thickness and hardness should be higher in order to prevent deformation. However, the length of aluminum ceiling tiles used in home improvement is rarely more than four meters, and there are no heavy objects on the aluminum ceiling, so 0.6 mm thickness is enough.

Links:https://www.globefindpro.com/products/85906.html

-

FDM8120 Forklift Truck

FDM8120 Forklift Truck

-

FDM756T-18 Telehandler

FDM756T-18 Telehandler

-

FDM890 Forklift Truck

FDM890 Forklift Truck

-

1050 Mill Finish Aluminum Coil

1050 Mill Finish Aluminum Coil

-

1100 Mill Finish Aluminum Coil

1100 Mill Finish Aluminum Coil

-

Stone Coated Metal Roof Tiles (Roof Shingle)

Stone Coated Metal Roof Tiles (Roof Shingle)

-

PVDF Coated Aluminum Coil

PVDF Coated Aluminum Coil

-

Stone Coated Metal Roof Tiles (Rainbow Tile)

Stone Coated Metal Roof Tiles (Rainbow Tile)

-

3003 Mill Finish Aluminum Coil

3003 Mill Finish Aluminum Coil

-

FDM880 Forklift Truck

FDM880 Forklift Truck

-

Stone Coated Metal Roof Tiles (Classic Tile)

Stone Coated Metal Roof Tiles (Classic Tile)

-

8011 Mill Finish Aluminum Coil

8011 Mill Finish Aluminum Coil