Bell Annealing Furnace

There are three activities taking place in the bell annealing furnace. First off, several loose or tight steel coils are stacked in a pile. Then, they are placed into the oven, enclosed by an inner cover. Finally, the coil is heated to a pre-set temperature and remains at that temperature for a few minutes before cooling it down.

This bell annealing furnace is able to cope with strips that are made of carbon steel, Martensitic stainless steel, silicon steel, or non-ferrous metal. Heating energy sources available for the heat treatment furnace include the electricity, gas and oil. During the annealing process, the inner over seals in a protective atmosphere that contains a large portion of hydrogen and a small portion of nitrogen. To ensure a uniform heat distribution within the heating chamber as well as enhance productivity, a fan is added to the bell annealing furnace to increase the speed of protective gas circulation within the inner oven.

As is mentioned in the above, the heat treatment equipment can use electricity for heating source. The heating element utilizes the electrical resistance strip which is made of 0Cr25AL5 that can resist a high temperature of 1000°C.

The outer cover for the bell annealing furnace is made of Q235 carbon steel, with a thickness of 6mm.

The inner cover is made of 0Cr18Ni9 stainless steel, with a thickness of 8mm.

Air-water dual cooling system delivers high cooling performance while requiring little cooling time. The cooling cover for the annealing machine is mad of Q265 carbon steel, with a thickness of 6mm.

Links:https://www.globefindpro.com/products/85940.html

-

Annealing and Pickling Line (For Stainless Steel)

Annealing and Pickling Line (For Stainless Steel)

-

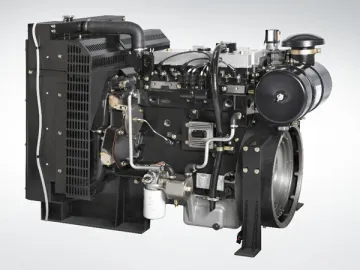

Genset Engine

Genset Engine

-

Continuous Pickling Line(for Strip Steel)

Continuous Pickling Line(for Strip Steel)

-

Welding Machine

Welding Machine

-

Color Coating Line (for Strip Steel)

Color Coating Line (for Strip Steel)

-

FDM766T-28 Telehandler

FDM766T-28 Telehandler

-

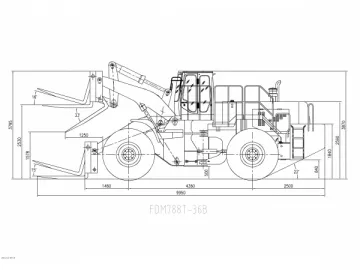

FDM788T-36B Telescopic Handler

FDM788T-36B Telescopic Handler

-

FDM8200 Forklift Truck

FDM8200 Forklift Truck

-

Steel Storage Unit

Steel Storage Unit

-

Annealing Furnace

Annealing Furnace

-

Continuous Annealing Line (For Strip Steel)

Continuous Annealing Line (For Strip Steel)

-

LOVOL® Generator Set Engine

LOVOL® Generator Set Engine