Color Coating Line (for Strip Steel)

The color coating line is one of our strip processing lines engineered for strip steel corrosion prevention purpose. On the coil coating line, colored paint is repeatedly applied to the galvanized and galvalume steel to produce a dazzling surface with enhanced corrosion-resistance. Major processes involved in this color coating line include degreasing, cleaning, painting, drying and curing.

Our patented color coating line creates a mix of benefits to appeal to customers. With this coil coating machine, a uniform coating, accurate coating thickness measurement accuracy, and reduced setup time can be achieved to ensure product quality and improve productivity.

Application Areas

As the name suggests, the major function of our color coating line is to place multiple layers of color paints onto the strip steel surface. Color-coated strip is highly malleable, corrosion-resistant, and mechanically strong. In addition to serving a utilitarian purpose, the plate also adds decorative glamour to the object due to its brilliant color. Recent years has seen its widespread use in construction, household appliance, and transportation industries as well as light industry.

Process Flow of the Color Coating Line

Coil Transfer Car—Pay-Off Reel—Pinch Roll—Shear—Welding Machine—Bridle Roll—Storage Device—Bridle Roll—Cleaning Section (including brusher roll, cleaning system, and squeegee roll)—Hot Air Blowpipe—Chemical Roller—Drying Oven—Bridle Roll—Steering Roll—Under Coat Applying Roll—Primer Curing Oven—Air Cooling Device—Water Cooling Device—Steering Roll—Top-Coat Coating Machine—Top-Coat Curing Oven—Air Cooling Device—Water-Cooling Device—Bridle Roll—Material Storage Device—Bridle Roll—Shear—Pinch Roll—Rewinder—Coil Transfer Car

Major Coil Processing Equipment for Composing the Strip Steel Color Coating Line

| In terms of driving mode, our roll coater adopts the independent drive manner. Each roll is separately equipped with a drive motor. As with this drive motor, the rotating direction and rotating speed can be changed within their allowable range. | |

| The industrial drying oven is comprised of oven body, internal ducting, cross-flow oven, air circulation fan, and external ducting. It promotes drying by efficient application of air re-circulated heat. |

Links:https://www.globefindpro.com/products/85945.html

-

FDM766T-28 Telehandler

FDM766T-28 Telehandler

-

Bright Annealing Line(For Stainless Steel)

Bright Annealing Line(For Stainless Steel)

-

Tension Leveler

Tension Leveler

-

Electrolytic Tinning Line (for Strip Steel)

Electrolytic Tinning Line (for Strip Steel)

-

Hot Dip Galvanizing Line and Galvalume Line (for Strip Steel)

Hot Dip Galvanizing Line and Galvalume Line (for Strip Steel)

-

FDM720T Wheel Loader

FDM720T Wheel Loader

-

Welding Machine

Welding Machine

-

Continuous Pickling Line(for Strip Steel)

Continuous Pickling Line(for Strip Steel)

-

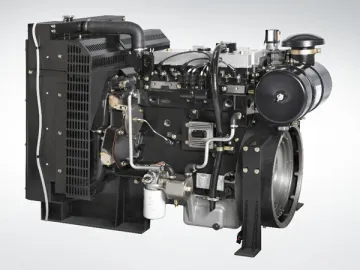

Genset Engine

Genset Engine

-

Annealing and Pickling Line (For Stainless Steel)

Annealing and Pickling Line (For Stainless Steel)

-

Bell Annealing Furnace

Bell Annealing Furnace

-

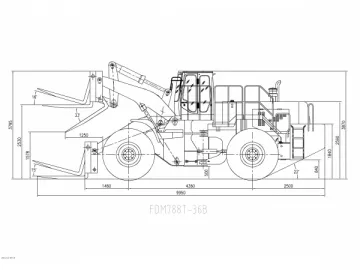

FDM788T-36B Telescopic Handler

FDM788T-36B Telescopic Handler