Tension Leveler

Also called roller leveler, the tension leveler is a piece of strip steel finishing equipment. It stretches, bends, and straightens the strip, thereby eliminating edge wave, coil set, cross bow, camber, and a combination of defects. The result is that the steel strip obtains improved quality. Following is a list of main features of our tension leveler.

1. The framework of the tension leveler exhibits good rigidity. This ensures a stable, dependable operation.

2. This type of coil processing equipment offers higher precision in leveling, as compared with other types of sheet metal levelling machines such as the staightener, flattener, or shape correction leveler.

3. Allow ease of installation, inspection, and commissioning.

4. The tension leveling machine is equipped with a pair of roller housings. Users can use both of them at the same time, or one for use and one for back-up.

5. When the welding joint, or welding seam to be more precise, is fed through the two rows of rolls, the housing can be opened to facilitate the pass of the seam. After the welding seam is passed, the housing can be pressed down quickly.

6. The lower row of tension leveler rolls and deflector rolls coordinate with each other to remove the cross bow.

7. The upper row of leveler rolls and deflector rolls cooperate with one another to reduce set coil.

8. The tension leveler is available with a carriage for use during roll change. It can pull out one or even the entire housing. The upper roller housing can be flipped over on the carriage to allow ease of roll replacement.

Links:https://www.globefindpro.com/products/85948.html

-

Electrolytic Tinning Line (for Strip Steel)

Electrolytic Tinning Line (for Strip Steel)

-

Hot Dip Galvanizing Line and Galvalume Line (for Strip Steel)

Hot Dip Galvanizing Line and Galvalume Line (for Strip Steel)

-

FDM720T Wheel Loader

FDM720T Wheel Loader

-

Cleaning Unit

Cleaning Unit

-

Diesel Engine Water Pump

Diesel Engine Water Pump

-

Genset Controller

Genset Controller

-

Bright Annealing Line(For Stainless Steel)

Bright Annealing Line(For Stainless Steel)

-

FDM766T-28 Telehandler

FDM766T-28 Telehandler

-

Color Coating Line (for Strip Steel)

Color Coating Line (for Strip Steel)

-

Welding Machine

Welding Machine

-

Continuous Pickling Line(for Strip Steel)

Continuous Pickling Line(for Strip Steel)

-

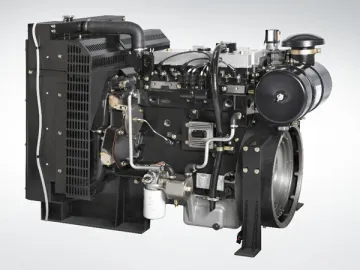

Genset Engine

Genset Engine