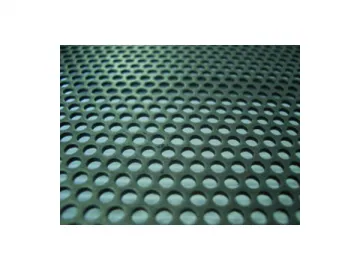

Galvanized Steel Sheet Anode

Electrogalvanizing refers to coating Zn or Sn on both sides of steel strip, and it is commonly applied to process automobile and home appliance. Our galvanized steel sheet anode is especially designed for this process.

The electrogalvanizing line comprises of some electrolytic tanks. Inside each of the tank, there are several titanium anodes with IrO2 coating. The steel strip travels through these tanks with a high speed, and the distance between anode and cathode is about 2cm.

This process involves zinc deposition at a high current density (6-10kA/m2) from the made-up electrolyte compositions (30% H2SO4, 1mol/L ZnSO4, PH=1.5), and the temperature is 55℃. In addition, a titanium anode with IrO2-Ta2O5 coating has a very long life span which is over 40,000kAh.

Related Names

Cold Galvanizing Process | Zinc Coated Steel Maker | Electro Galvanized Steel

Links:https://www.globefindpro.com/products/85955.html

-

Weichai Diesel Generator Set

Weichai Diesel Generator Set

-

Daewoo Diesel Generator Set

Daewoo Diesel Generator Set

-

Expandable Anode

Expandable Anode

-

Anode for Etching/Corrosive Liquid Copper Recovery

Anode for Etching/Corrosive Liquid Copper Recovery

-

Activated Cathode Chamber

Activated Cathode Chamber

-

Low Power Diesel Generator Set

Low Power Diesel Generator Set

-

Genset Controller

Genset Controller

-

Diesel Engine Water Pump

Diesel Engine Water Pump

-

Cleaning Unit

Cleaning Unit

-

FDM720T Wheel Loader

FDM720T Wheel Loader

-

Hot Dip Galvanizing Line and Galvalume Line (for Strip Steel)

Hot Dip Galvanizing Line and Galvalume Line (for Strip Steel)

-

Electrolytic Tinning Line (for Strip Steel)

Electrolytic Tinning Line (for Strip Steel)