Expandable Anode

We have a complete set of production machines for expandable anode, and we are well experienced in this field.

| Used expandable anode | Disassembled flat springs |

| Welding process | Refurbished expandable anode |

Advantages

1. All the heating devices adopt computer-aided temperature control technology, and the automatic multi-head welding machine, which is exclusive in China, is used to finish spot welding process for the mesh. Moreover, the flat spring is fabricated by high quality Ti material that is imported from Japan, and it can still expand evenly after long-term service.

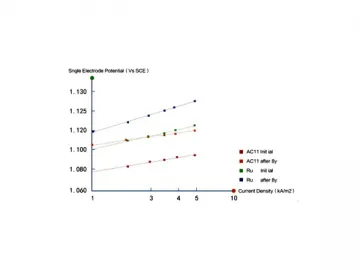

2. The anode coating is manufactured via advanced technique, and it features long service life, low half-cell potential, little and slow potential rise, etc. This coating can fully meet the requirements of expandable anode even if high current density is applied.

3. Under the same working condition, the cell voltage shows an obvious drop which can reach up to 0.15V-0.2V or even higher. In addition, the production capacity is improved by 25% when the current density is 2200A/m2.

Related Names

Anode Electrolytic Processes | Electrochemical Anode | Diaphragm Cell Electrolysis

Links:https://www.globefindpro.com/products/85958.html

-

Anode for Etching/Corrosive Liquid Copper Recovery

Anode for Etching/Corrosive Liquid Copper Recovery

-

Activated Cathode Chamber

Activated Cathode Chamber

-

Low Power Diesel Generator Set

Low Power Diesel Generator Set

-

BiTAC Electrolyzer

BiTAC Electrolyzer

-

Ion-exchange Membrane Electrolyzer Anode Coating

Ion-exchange Membrane Electrolyzer Anode Coating

-

MGC Electrolyzer

MGC Electrolyzer

-

Daewoo Diesel Generator Set

Daewoo Diesel Generator Set

-

Weichai Diesel Generator Set

Weichai Diesel Generator Set

-

Galvanized Steel Sheet Anode

Galvanized Steel Sheet Anode

-

Genset Controller

Genset Controller

-

Diesel Engine Water Pump

Diesel Engine Water Pump

-

Cleaning Unit

Cleaning Unit