UHDE Electrolyzer

We have repaired or recoated a great deal of UHDE electrolyzers in different factories home and abroad, and our work is highly appreciated by the customers. After refurbishment and recoating, the UHDE electrolyzer meets the technical requirements that are designed for a new product, and it is able to deliver safe and stable performance to the customer.

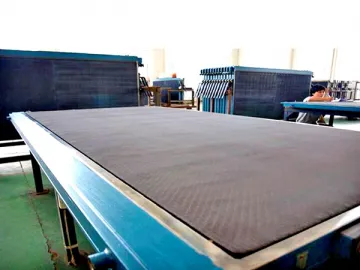

| BM-2.7: Before Repair | |

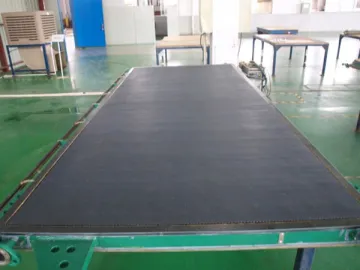

| BM-2.7: After Repair | |

| Zero Gap Modification for BM-2.7 | |

1. The original isolating bar is removed to increase the reaction area of electrode, and the elastic mesh at the cathode is also well protected.

2. A flat mesh is added to the anode to cut down the maintenance time.

3. The cathode takes advantage of specially constructed elastic mesh and activated mesh directly to lower the cell voltage. In addition, the average cell voltage will drop by 100mV after repair.

| GORE joint sealant | Fastening components |

| Fastening components | Main pipe for brine (CPVC) |

| Main pipe for catholyte (PPH) | Feed distribution pipe (PPH) |

Available Accessories

| No. | Name | Material |

| 1 | Feed distribution pipe | PTFE |

| 2 | Anode insert tube | PTFE |

| 3 | Cathode insert tube | PTFE |

| 4 | Frame gasket | TFM1600 |

| 5 | Sealing strip | - |

| 6 | Hex bolt with shrinkable tube | 10.9G 3E |

| 7 | M10 hex nut | 10.9G 3E |

| 8 | Conical spring washer with special coating | 50Cr V4 |

| 9 | Insulating washer | HGW 2372.1 or Permaglass TE602 |

| 10 | Insulating bush | PTFE |

| 11 | Ion-exchange membrane | Specialized |

| 12 | Inlet hose | PTFE/1.4571 |

| 13 | Pipe fitting | 14.435 |

| 14 | Outlet hose | PTFE/1.4571 |

| 15 | Insert tube | PTFE |

Related Names

Electrode Recoating Service | Hydrogen Conversion Kit | Chemical Cell Technology

Links:https://www.globefindpro.com/products/85979.html

-

Titanium Anode for Electrolytic Copper Foil Production

Titanium Anode for Electrolytic Copper Foil Production

-

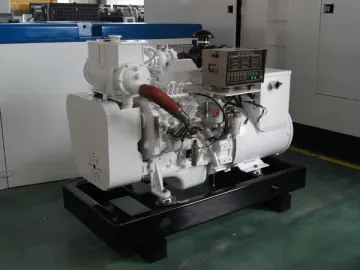

Marine Diesel Generator Set

Marine Diesel Generator Set

-

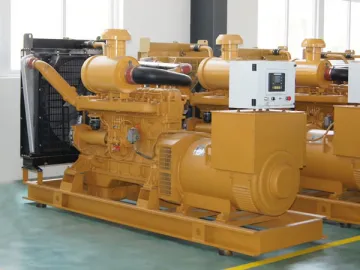

SDEC Diesel Generator Set

SDEC Diesel Generator Set

-

Asahi Kasei Electrolyzer

Asahi Kasei Electrolyzer

-

Deutz Diesel Generator Set

Deutz Diesel Generator Set

-

HG-24 Eames La Chaise

HG-24 Eames La Chaise

-

Volvo Diesel Generator Set

Volvo Diesel Generator Set

-

Wuxi Power Diesel Generator Set

Wuxi Power Diesel Generator Set

-

DD350 Electrolyzer

DD350 Electrolyzer

-

Yuchai Diesel Generator Set

Yuchai Diesel Generator Set

-

Perkins Diesel Generator Set

Perkins Diesel Generator Set

-

Silent Diesel Generator Set

Silent Diesel Generator Set