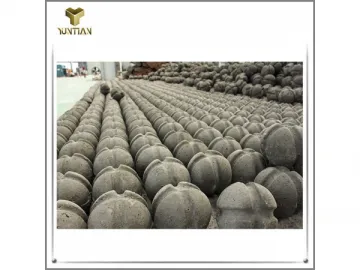

Slag Stopper Ball

We are expert in manufacturing the slag stopper ball. With the diameter ranging from 150cm to 300cm, the ball shaped slag stopper can serve the BOF converter with the specification of 8 to 120t. The new type environmental friendly magnesian product is free of sulfer and phosphorus. It won’t pose pollution.

Physical and Chemical Indicators

| Item | Index Value |

| MgO | ≥70% |

| Volume Density | ≥4.0-4.2g /cm3 |

| Ambient Compressive Strength | 20 Mpa |

| Refractoriness | ≥1790°C |

The slag stopper ball was invented by the Japanese Nippon Steel Corporation in 1970. It blocks the tapping hole when the steel tapping is about to end to prevent the steel slag from flowing into the ladle by exploiting the principle of the density of the product being between that of the steel and slag, generally with the value of 4.2 to 4.5g/cm³.

Our slag stopper ball is distributed with steel flowing groove on its outside. It drifts to get to the steel tapping hole. It is proven by practical use through many steelmaking enterprises that the slag stopping effective rate can be as high as 75% to 80% by using our slag stopping ball. Approximately, each ton of the steel would generate the slag weighing more than 5kg or so. The specific gravity of the slag stopper ball is crucial. If it is too small, the slag cannot be held back. On the contrary, the slag balls with too big specific gravity cannot let the molten steel go out completely. Our product meets a wide range of process needs. It is beneficial to the enhancement of the molten steel quality.

Related Names

Ball Shape Slag Stopper Manufacturer | BOF Converter Products | Refractory Shape for Slag Control

Links:https://www.globefindpro.com/products/86307.html

-

Slag Darts (for 30-150 Ton BOF Converters)

Slag Darts (for 30-150 Ton BOF Converters)

-

Komatsu Excavator Idler

Komatsu Excavator Idler

-

Slag Stopper (Used Outside BOF Converters)

Slag Stopper (Used Outside BOF Converters)

-

8m DD6850K02F Tour Bus

8m DD6850K02F Tour Bus

-

Shrinking-pores Essential Oil

Shrinking-pores Essential Oil

-

French Gold Collagen Eye Mask

French Gold Collagen Eye Mask

-

Tungsten Steel Circular Knife

Tungsten Steel Circular Knife

-

Vagina-Shrink Essential Oil

Vagina-Shrink Essential Oil

-

Face Care Rose Essential Oil

Face Care Rose Essential Oil

-

Organic Whitening Moisturizing Essence

Organic Whitening Moisturizing Essence

-

Eye Essence

Eye Essence

-

Hexapeptide Essence

Hexapeptide Essence