Slag Darts (for 160-300 Ton BOF Converters)

A large number of steel slag would come into being in the converter steelmaking production process, and this may cause lowered quality of molten steel. Our range of slag darts is designed for slag control during steelmaking process, and thus is a kind of commonly used refractory material in BOF converters. The slag control system is suitable for BOF converters with capacity from 160 to 300t.

Our slag darts can make the slag stopping efficiency up to 96% with the slag layer thickness no greater than 40mm. The new technology can cut down the energy consumption, lessen the temperature loss of the molten steel and improve the safety of the steelmaking operation.

Physical Index

| Model | Volume Density | Compressive Strength | Refractoriness | |||

| Sphere Part | Guide Bar Part | Sphere Part | Guide Bar Part | Sphere Part | Guide Bar Part | |

| M-1 | 4.1g /cm³ | 3.9g /cm³ | (110°C ×24h) 40Mpa | 40Mpa | 1790°C | 1790°C |

| (1500°C ×3h) 60Mpa | 50Mpa | |||||

| A-1 | 4.1g /cm³ | 3.9g /cm³ | (110°C ×24h) 50Mpa | 40Mpa | 1790°C | 1790°C |

| (1500°C ×3h) 70Mpa | 50Mpa | |||||

Chemical Index

| Name | Model | Sphere Part | Guide Bar Part |

| MgO | M-1 | 60% | 60% |

| Al 2O 3 | A-1 | 60% | 60% |

Note

1. M-1 represents slag darts made of magnesium oxide. A-1 refers to ones made of aluminium oxide.

2. The volume density of the slag blocking dart can be in line with the application demands of customers.

3. The screw-thread steel of the guide bar can be customized according to the drawing of the customers in length and size.

While, the traditional way for stopping slag is applying the slag stopping ball which gets to the steel tapping hole generally in the form of drifting. Plus the high steel slag viscosity, the slag stopping ball cannot achieve steel tapping hole or cannot make the steel tapping hole blocked effectively when the molten steel is going to drain away. Therefore, the efficiency of the application of slag stopping ball is usually below 70%. Our slag darts are perfect replacement of conventional slag stopper balls.

Links:https://www.globefindpro.com/products/86315.html

-

Shantui Bulldozer Blade Cutting Edge

Shantui Bulldozer Blade Cutting Edge

-

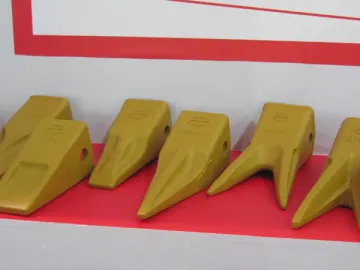

Komatsu Excavator Bucket Teeth

Komatsu Excavator Bucket Teeth

-

Komatsu Excavator Track Roller

Komatsu Excavator Track Roller

-

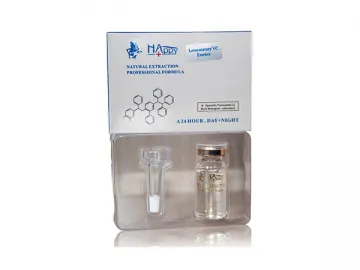

Levorotatory VC Essence

Levorotatory VC Essence

-

Wrinkle Lifting Cream

Wrinkle Lifting Cream

-

HG-E7 Side Table

HG-E7 Side Table

-

Brightening Moisturizing Face Mask

Brightening Moisturizing Face Mask

-

French Gold Collagen Eye Mask

French Gold Collagen Eye Mask

-

Shrinking-pores Essential Oil

Shrinking-pores Essential Oil

-

8m DD6850K02F Tour Bus

8m DD6850K02F Tour Bus

-

Slag Stopper (Used Outside BOF Converters)

Slag Stopper (Used Outside BOF Converters)

-

Komatsu Excavator Idler

Komatsu Excavator Idler