Slag Foaming Agent

Slag Foaming Agent

The domestic and foreign steelmills improve the converter slag making by giving priority to improving the slagging material. Choosing good slag foaming agent andcoolant is an important way to optimize the converter steelmaking slag formingprocess.

The high efficient composite slag forming constituent is also a kind of good coolant. It canfulfill the requirements of the converter steelmaking slag making processcompletely. The main ingredients of the slag foaming agent are calcium ferrite,calcium aluminate, calcium manganate, etc. Featuring low melting point and high slagging speed, the slag foaming agent ismuch superior to the traditional singly used slag making materials like lime,calcium fluoride, pellet, etc.

Highlights

1. Fast slagging speed.

The slaggingagenthas low melting point. After being added into the converter, it forms the slagforming solution quickly. Meanwhile, the solution contacts with and penetratesinto the lime to accelerate the dissolution of the lime, thus generating thefast slag making effect.

2. Stabilizing the converter blowing melting process and reducing thesplashing.

By using the slag foaming agent,the blowing melting process is stable and the slag is in good condition.Meanwhile, the frequency of splashing caused by the reasons including slaggetting dry can be greatly reduced. The slag former is also propitious forreducing the iron loss, decreasing the loss of the oxygen lance, cutting downthe metal loss and equipment accident rate induced by the splashing, saving thecost and time for cleaning the furnace mouth and oxygen lance arising fromsplashing, as well as improving production efficiency.

3. More stable and better dephosphorization effect than single lime slag making.

The slag foaming agentis fast in slagging speed. Its phase composition is a kind of good dephosphorization slag. Before the lime melts,the slagforming agent reacts with the phosphorus in the molten steel, startingthe prophase dephosphorization. Along with the melting of the lime, thedephosphorization effect is consolidated andstrengthened continuously. The dephosphorization rate is higher than that of single limeslag making by 2% to 4%.

4. Excellent fluxing medium.

The slag foaming agentcan replace the calcium fluoride completely to relieve the erosion andpollution of the calcium fluoride to the furnace lining and the environment.Moreover, the appropriate amount of MgO in the high efficient composite slagfoaming agent can balance the content of MgO in the initial slag to reduce theerosion of the initial slag to the furnace lining for enhancing the servicelifetime of the converter.

5. Shortening the blowing melting time and improving the converter productioncapability.

The slag foaming agent can lead to goodsteelmaking effect in fast slagging speed, stable blowing melting, rapid dephosphorization in the prophase, little splash and low accident rate. It can ensuresmooth steelmaking process. The smelting period can be shortened by 1 to 2minutes which is about 10% of the blowing melting time.

6. Lower material consumption.

The high efficient composite slag making agent contains the FeO and MnO, which can diminish therequisite oxidation amount of ferrum and manganese for the slag forming in the prophase. Thus,the oxygen blowing amount falls down accordingly. The blowing loss drops. Thecontents of Mnand C in the final molten steel are raised appropriately.

Under normal circumstances, by adding slag foamingagent of 1kg into 1tsteel, the oxygen blowing amount can be decreased by 1%, and the residualmanganese in the molten steel is heightened by 0.002%. Meanwhile, the amount ofthe lime, metal loss and the coolant amount are cut down by 0.5 to 0.6kg, 0.06% to 0.1% and 0.6 to 1kg separately.

Links:https://www.globefindpro.com/products/86325.html

-

LED-328 GPRS Wireless LED Control Module

LED-328 GPRS Wireless LED Control Module

-

S Series Infrared Touchscreen

S Series Infrared Touchscreen

-

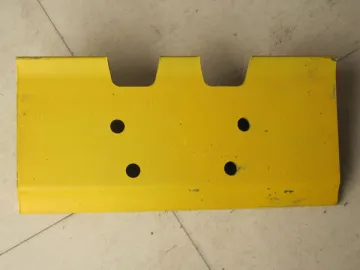

Shantui Bulldozer Track Chain and Track Shoe

Shantui Bulldozer Track Chain and Track Shoe

-

Slag Dart Dispatching Machine (Robot for Slag Dart Insertion)

Slag Dart Dispatching Machine (Robot for Slag Dart Insertion)

-

Gold Collagen Face Mask

Gold Collagen Face Mask

-

Komatsu Excavator Counter Weight

Komatsu Excavator Counter Weight

-

Whitening Essential Oil

Whitening Essential Oil

-

Filters

Filters

-

Collagen Crystal Eye Mask

Collagen Crystal Eye Mask

-

HG-E7 Side Table

HG-E7 Side Table

-

Wrinkle Lifting Cream

Wrinkle Lifting Cream

-

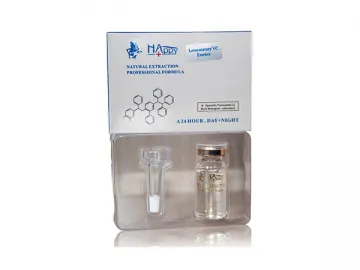

Levorotatory VC Essence

Levorotatory VC Essence