Slag Dart Dispatching Machine (Robot for Slag Dart Insertion)

The slag dart dispatching machine is an automatic robot for slag dart insertion. It automatically inserts slag darts into the taphole, thus reducing slag carryover from the BOF converter. It also supports manual operation in case of PLC system failure.

Product Model

| Model | YTD- I | YTD- II | YTD- III |

| Specification of Applicable Converter (t) | 30-60t | 70-150t | 160-300t |

Highlights

1. Advanced technology. By taking the PLC control, the slag dart dispatching machine actualizes the mechanical, electrical and hydraulic integration. In comparison with the similar foreign slag dart machine sets, the machine developed by ourselves is provided with the adaptive parameter adjusting technology in line with mathematical model, encoder control and automatic tracking angle change of converter. It is proven through the data retrieval that the technology originates with us.

2. Complete functions. The slag dart dispatching machine can realize both manual control and unmanned operation via the program automatic control. The reliable manual operation rules are set especially for facing the condition of the PLC control fails to work under high temperature environment. Additionally, when the slag dart launch machine works through infrared remote control, the worker cannot operate the equipment manually.

3. Simple and intuitive operation. The slag dart dispatching machine is fitted with an operator-friendly operation panel.

4. Accurate work. Thanks to the technologically leading measurement and control means, variable frequency speed control as well as the superior secondary positioning concept in the design, the slag dart releasing machine is two times higher than the similar foreign device in integral position accuracy. The release point hit accuracy of the similar foreign equipment is ±50mm. While that parameter of our product falls to ±20mm in design and ±11mm in actual measurement.

5. Reliable work. The slag dart dispatching machine avails itself of a variety of effective protective measures and emergency operations coping with the accident conditions. In the case of no power supply, the equipment can exit from the converter safely in virtue of its own performance. With regard to the mechanical and electrical aspects, it has the reliable thermal protection means.

6. Powerful software function. When designing the control software, we set two parallel control processes for one action in the interest of priority execution, enhancing the reliability of control enormously.

7. Easy maintenance. The device can be installed and dismounted easily. Under high temperature, the working cantilever bar is the vulnerable part. Its delicate physical design makes the replacement much easier. The whole replacement process won’t cost half an hour.

8. Compact arrangement. The slag dart dispatching machine only occupies the area within 2500mm range of the platform at the back of the converter by leaning close to the platform railing.

9. High performance price ratio. On the basis of complete functions and reliable quality, the product only costs 1/5 of the similar foreign equipment in price.

Brief Introduction of Working Process

The crucial part of the equipment is an arm-like manipulator. In the case of extension length exceeding 6m, the manipulator can hold the slag dart weighing about 30 to 45kg in 1600°C radiation environment.

When the converter tilts to near the predetermined angle, the slag dart dispatching machine tracks the position of the tapping hole of the converter and inserts the slag dart guide bar into the tapping hole at the appropriate steel tapping moment. Then, the manipulator clamping the slag dart releases. The slag dart floats on the interface of the molten steel and slag at the desired point, thus finishing the prescribed technical process.

The product is arranged on the operational platform at the back of the converter. We design the specification of the equipment by fully considering the plane size of the platform as well as the adaptability for different converter capacities. Through small changes, the product can be upgraded for fitting for the converter with the specification ranging from 30t to 300t.

Composition

The slag dart dispatching machine is constituted of the following parts.

1. Guide Rail. It is composed of the track, related fastener and the fixed baffle at the end of the track. The guide rail is laid on the operational platform at the back of the converter with its top surface flush with the platform.

a. Type of the track: 24kg/m

b. Track gauge (center line): 1200mm

c. Track length: about 6 to 10m

2. Platform Car. It is the welded structure, including the frame, pivotal bearing, wheel assembly and the driving unit. The platform car carries the rotary working platform and hydraulic system.

a. Width: 1400mm

b. Length: 2450mm

c. Track gauge (center line): 1200mm

d. Rail pressure: 2t (front), 2.5t (back)

e. Stroke: >4

f. Moving speed: 2 to 30m/min

g. Positioning speed: <±20mm

3. Rotary Working Platform. With the structure of welded type, it is equipped with the manipulator telescopic driving device, manipulator tilting hydraulic cylinder and operational cabinet for operator. A protective baffle is set before the rotary platform for thermal radiation protection. The working platform can rotate in the vertical direction with certain angle of 90°.

4. Manipulator. It can achieve up and down pitching movement as well as stretching out and drawing back in line with the customers' application situation. At the front end of the manipulator, there is a clamp holder controlled through the hydraulic system. The telescopic movement, in the case of the telescopic movement is available, is actualized via the variable frequency speed adjusting device. The manipulator is the tubular structure and split into the main parts of front, rear and clamp holder. Each part is connected through bolt. The manipulator is welded structure at its front and rear parts. It is cooled through compressed air.

a. Length of the slag dart: 1000 to 1650mm

b. Diameter of the slag dart rod: 40 to 50mm

5. Hydraulic system. It is basically comprised of motor for hydraulic pump, control circuit valve block and fuel tank.

6. Electric device. It includes control cabinet and operational panel. The electric control function can meet all the requirements of automatic and manual operation as well as the interlocking requirement between the equipment.

7. Energy medium supply system. The electricity and air supply cable and hose share a set of hanging rail pulley device. The converter steelmaking computer transmits the tilting angle signal to the slag dart dispatching machine. The power supply is AC 380V with the total power of 7.5kW or so.

8. Air compressing system. The pressure of the compressed air at the connection point is 5bar. The compressed air consumption for each tap-to-tap time in the converter is 15m³.

We have strong technical advantages in converter tapping slag stopping technology and equipment. Many steel mills have purchased our slag stopping device. The success dispatching rate of our especially developed slag dart dispatching machine is higher than 98%. By reason of the leading technical indexes, stable performance as well as the reliable and safe operation, it gains high praise from the users widely.

Related Names

Industrial Furnace Tool | Mechanical Device for Slag Processing | China Slag Dart Dispatcher Manufacturer | Workshop Equipment

Links:https://www.globefindpro.com/products/86329.html

-

Gold Collagen Face Mask

Gold Collagen Face Mask

-

Komatsu Excavator Counter Weight

Komatsu Excavator Counter Weight

-

Shantui Bulldozer Sprocket

Shantui Bulldozer Sprocket

-

Slag Dart Tail

Slag Dart Tail

-

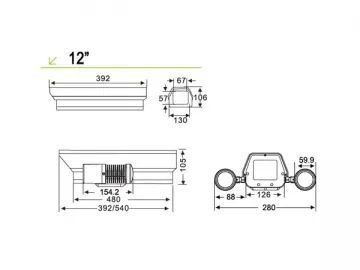

IRH160G-IP IP Camera IR Illuminator Housing

IRH160G-IP IP Camera IR Illuminator Housing

-

Anti-Aging Astaxanthin Essence

Anti-Aging Astaxanthin Essence

-

Shantui Bulldozer Track Chain and Track Shoe

Shantui Bulldozer Track Chain and Track Shoe

-

S Series Infrared Touchscreen

S Series Infrared Touchscreen

-

LED-328 GPRS Wireless LED Control Module

LED-328 GPRS Wireless LED Control Module

-

Slag Foaming Agent

Slag Foaming Agent

-

Whitening Essential Oil

Whitening Essential Oil

-

Filters

Filters