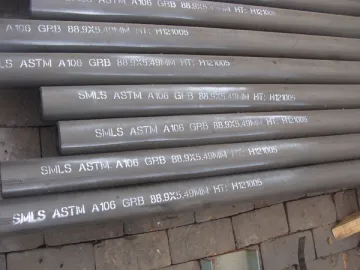

ASTM Seamless Pipes

The ASTM seamless pipe is a long pipe with hollow tubular cross section and without seams around its circumference. It is commonly used to transfer fluids such as the natural gas, coal gas, water and some solid materials.

The seamless pipe has the same torsional strength as the solid round bar while the former gives lighter weight and cost advantage. It is widely employed to make structural member and mechanical parts, such as the drill rod, drive shaft, bicycle frame, and steel scaffolding used in construction.

Utilizing seamless pipes to make circular parts minimizes the use of raw material, simplifies the manufacturing process and saves manufacturing time. Typical examples of circular parts are the outer and inner rings of rolling bearing as well as the jack bushing. In addition, the pipe is an indispensable item in making conventional weapons including guns and artilleries.

Steel pipes can be divided into two types: round or irregularly shaped, depending on the shape of their cross-section. Suppose you have two pipes of the same perimeter. One is round and the other has a cross section of any shapes other than a round one. It has been proved that the round pipe has the biggest cross-section area among all the pipes in various non-circular shapes. Hence, the round pipe can transfer the largest amount of fluids. In addition, a round pipe tends to distribute the internal and external radial stress more evenly. In sum, it is reasonable to make pipes into a round shape.

ASTM A53/106B

1. Process: cold drawing, hot-rolling, hot expanding

2. Standard: ASME B36, 10, ASTM A106/A53, SA53/106

3. Specification range:

OD: 1/2"-24"

WT: SCH10-SCHXXS

4. Materials: 10#, 20#, 45#, 16Mn, GRB, Q345B, X42-56, ST44, ST52 etc.

5. Testing: eddy current, hydrostatic, ultrasonic, intergranular corrosion etc.

6. Packing: in bundles with steel strips, seaworthy packing as per customer's requirements

7. Application: ASTM A106/53 GRB seamless pipe is widely used in petroleum industry and power station to convey natural gas, coal gas, water and some solid materials.

| Standard | Grade | Chemical Composition | Mechanical Properties | |||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | V | Tensile Strength (Mpa) | Yield Strength (Mpa) | ||

| ASTM A106 | A | ≤ 0.25 | ≤ 0.10 | 0.27- 0.93 | ≤ 0.035 | ≤ 0.40 | ≤ 0.15 | ≤ 0.40 | ≤ 0.40 | ≤ 0.08 | ≥330 | ≥205 |

| B | ≤ 0.30 | ≤ 0.10 | 0.29- 1.06 | ≤0.035 | ≤ 0.40 | ≤ 0.15 | ≤ 0.40 | ≤ 0.40 | ≤ 0.08 | ≥415 | ≥240 | |

| C | ≤ 0.35 | ≤ 0.10 | 0.29- 1.06 | ≤ 0.035 | ≤ 0.40 | ≤ 0.15 | ≤ 0.40 | ≤ 0.40 | ≤ 0.08 | ≥485 | ≥275 | |

| Standard | Grade | Chemical Composition (%) | Mechanical Properties | ||||||||||

| C | Si | Mn | P | S | Cu | Ni | Mo | Cr | V | Tensile Strength (Mpa) | Yield Strength (Mpa) | ||

| ASTM A53 | A | ≤ 0.25 | / | ≤ 0.95 | ≤ 0.05 | ≤ 0.045 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.40 | ≤ 0.08 | ≥330 | ≥205 |

| B | ≤ 0.30 | / | ≤ 0.05 | ≤0.05 | ≤ 0.045 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.40 | ≤ 0.08 | ≥415 | ≥240 | |

Related Names

Seamless Steel Liquid Piping | Round Steel Tubing | Water Supply Pipe

Links:https://www.globefindpro.com/products/86377.html

-

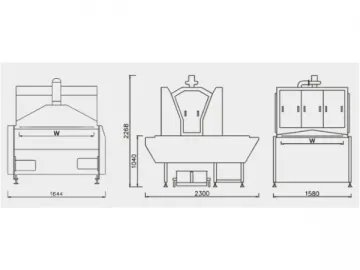

Horizontal Dough Mixer

Horizontal Dough Mixer

-

Electric Oven

Electric Oven

-

Biscuit Forming Machine

Biscuit Forming Machine

-

Oil Spray Unit

Oil Spray Unit

-

ZWJ Pump Mechanical Seal

ZWJ Pump Mechanical Seal

-

Conveyor before Baking Oven

Conveyor before Baking Oven

-

ZS Series Horizontal Single Stage Centrifugal Gravel Pump

ZS Series Horizontal Single Stage Centrifugal Gravel Pump

-

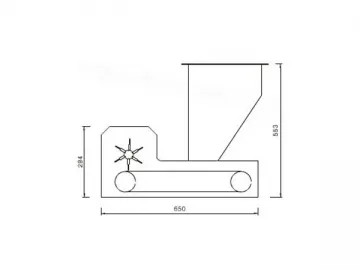

Rotary Cutter

Rotary Cutter

-

Salt/Sugar Sprinkler

Salt/Sugar Sprinkler

-

ZD Series Single Volute Slurry Pump for Metallurgical Industry

ZD Series Single Volute Slurry Pump for Metallurgical Industry

-

Gauge Rolls

Gauge Rolls

-

ZJ Pump Mechanical Seal

ZJ Pump Mechanical Seal