Other Biscuit Machines

The wire cutting machine is a kind of high-end processing equipment used for making cookies. The complete production line for cookie manufacturing includes the dough mixer, wire cutting machine, baking oven, oven drive and tension with steel band, stripping machine, cooling conveyor, pacing conveyor, etc.

2. Sesame Sprinkler

The sesame sprinkler is applied to the biscuits requiring sesame sprinkling. It is a kind of accessory equipment installed on the forming machine. Usually, the dough sheet should be rolled for three times and this machine will perform the fourth rolling after sprinkling the sesame onto the dough sheet. Thus, the sesame binding on the biscuits won’t readily come off.

3. Vacuum Salt and Sugar Suction Machine

This equipment is specially designed for high-end customers, and has high requirements for the production line. The salt or sugar sprinkled on the biscuit surface is easily spattered onto other machines, leading to machine corrosion. This equipment availably sucks all the salt or the sugar spattered on machines and thereby keeps machines tidy and clean.

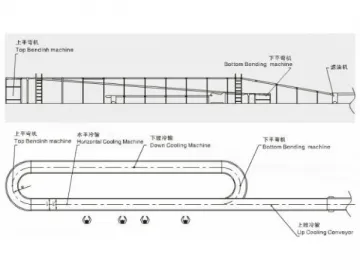

4. Bending MachineThis product is available in 90 degrees type and 180 degrees type. Based on the specific requirements of customers or the limitations of factory, the biscuit production line is not suggested to be designed into linear type or Z type, but should be provided with turn design.

The bending machine changes the cooling conveying directions of baked biscuits and makes the utmost of the factory space, providing sufficient time for biscuit cooling. When the direction is changed, it also ensures orderly biscuit arrangement. What should note is that applying multiple bending machines to one production line may lead to untidy biscuit stacking.

Related Names

Wafer Machine | Cookie Maker | Biscuit Processing Equipment

Links:https://www.globefindpro.com/products/86391.html

-

ZG(P) Series Centrifugal Slurry Pump for Gold Mining and Metallurgy Industry

ZG(P) Series Centrifugal Slurry Pump for Gold Mining and Metallurgy Industry

-

Dough Laminator

Dough Laminator

-

Vertical Dough Mixer

Vertical Dough Mixer

-

Cooling Conveyor

Cooling Conveyor

-

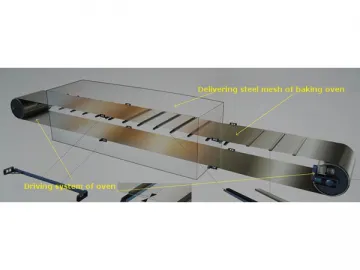

Driving System for Oven Band

Driving System for Oven Band

-

Rotary Moulder

Rotary Moulder

-

Roll Sheeter

Roll Sheeter

-

ZHR Series Rubber Lined Slurry Pump for Mining

ZHR Series Rubber Lined Slurry Pump for Mining

-

ZT Series Single Stage Centrifugal Desulfurization Pump for Power Generation

ZT Series Single Stage Centrifugal Desulfurization Pump for Power Generation

-

Egg Roll Machine

Egg Roll Machine

-

ZHH Series High-Head Slurry Pump for Mining and Building Material Industry

ZHH Series High-Head Slurry Pump for Mining and Building Material Industry

-

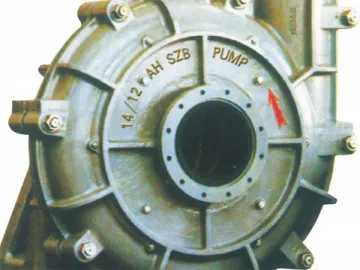

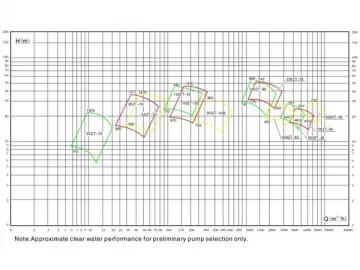

ZJ Series Horizontal Centrifugal Slurry Pump for Mining and Coal Industry

ZJ Series Horizontal Centrifugal Slurry Pump for Mining and Coal Industry