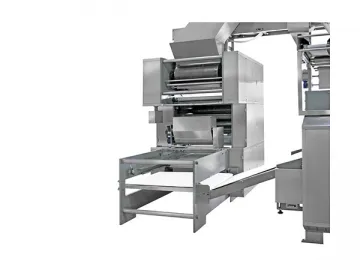

Dough Laminator

Descriptions

The dough laminator is the equipment mated with the biscuit forming machine. It is mainly used for manufacturing soda biscuits through a series of processing as dough rolling, compressing, laminating, conveying and forming. The biscuits it produces features distinct layering and crisp taste.

It adopts touch screen for easy control and all operations are recorded by computer providing reference for the later production. As it is jointly controlled together with the biscuit forming machine, production stability and continuity are well ensured.

The dough laminator is comprised of three parts, namely sheet rolling, laminating and streusel topping parts. The sheet rolling part utilizes 7 rollers for 4 times rolling, among which 3 rollers are together designed in triangular distribution, which can prevent the entrance of dough and realize 2 times rolling at the same time. The rest 4 rollers are grouped in pairs and perform 2 times rolling. A PU conveyer is configured between the two groups of rollers, which can effectively avoid the dough from being overstretched.

The laminating part is used for cut-sheet lamination of dough sheets. The conveyed dough sheet will be cut off and fall down after the carriage withdraws. Streusel topping is applied during the conveying of dough sheet. Under such processing, the biscuits possess the advantages as tidy laminating layers, multiple layers and even streusel topping. At last, the dough sheet will be conveyed to the forming machine.

Parameters

| Model | W1 (mm) | W2 (mm) | W3 (mm) | W4 (mm) | Laminated layers | Weight (T) | Power (KW) |

| HF600 | 1960 | 900 | 1760 | 2400 | 9-16 | 4.5 | 17.5 |

| HF800 | 2160 | 1100 | 1860 | 2600 | 9-16 | 5.5 | 19 |

| HF1000 | 2160 | 1100 | 1960 | 2800 | 9-16 | 5.5 | 19 |

| HF1200 | 2360 | 1300 | 2060 | 3000 | 9-16 | 6.5 | 20 |

Features

1. The components of the laminating part including the top carriage, top carriage conveyor, lower carriage, lower carriage conveyor and the cutter are driven by Simens high-precision durable servo motor 1FK7. We also adopt the SINAMIC S120 servo drive for accurate speed and positioning control, the dough sheet lamination is very speedy with multiple layers.

2. By adopting the dough laminator, the dough sheet is provided with uniform size and the sheet width is conveniently adjustable. The operation is easy and intelligent, suitable for long-term use without any failure.

3. This product comes with PLC control system as well as variable-frequency and variable-speed motor. Each unit is individually controlled and all the units also can be jointly controlled with high automaticity.

4. The cut-sheet lamination and even streusel topping are very desirable. The streusel topping width can be 700mm.

5. The streusel topping unit of this dough laminator adopts the brush roll which largely improves the production efficiency.

6. Continuous lamination is available, and the layers and dough sheet thickness are adjustable.

7. Both the streusel topping quantity and position can be adjusted.

Related Names

Dough Sheeter | Dough Flattening Machine | Saltine Cracker Maker

Links:https://www.globefindpro.com/products/86393.html

-

Vertical Dough Mixer

Vertical Dough Mixer

-

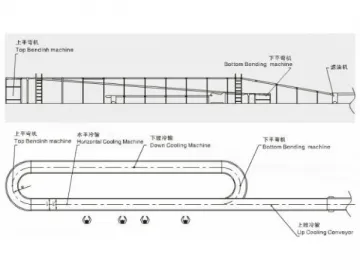

Cooling Conveyor

Cooling Conveyor

-

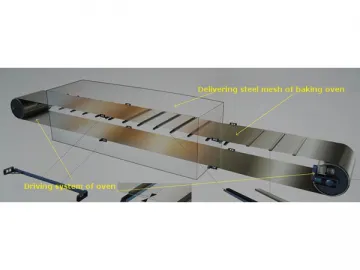

Driving System for Oven Band

Driving System for Oven Band

-

Rotary Moulder

Rotary Moulder

-

ZTL Series Single Stage Vertical Desulfurization Pump for Aluminium Metallurgy

ZTL Series Single Stage Vertical Desulfurization Pump for Aluminium Metallurgy

-

Biscuit Stacker

Biscuit Stacker

-

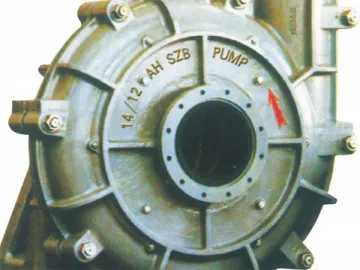

ZG(P) Series Centrifugal Slurry Pump for Gold Mining and Metallurgy Industry

ZG(P) Series Centrifugal Slurry Pump for Gold Mining and Metallurgy Industry

-

Other Biscuit Machines

Other Biscuit Machines

-

Roll Sheeter

Roll Sheeter

-

ZHR Series Rubber Lined Slurry Pump for Mining

ZHR Series Rubber Lined Slurry Pump for Mining

-

ZT Series Single Stage Centrifugal Desulfurization Pump for Power Generation

ZT Series Single Stage Centrifugal Desulfurization Pump for Power Generation

-

Egg Roll Machine

Egg Roll Machine