ZTL Series Single Stage Vertical Desulfurization Pump for Aluminium Metallurgy

The ZTL series single-stage vertical desulphurization pump is a new generation upgraded from ZM series. We have incorporated into this pump the advanced techniques utilized by many similar domestic and foreign products, to solve Chinese flue gas desulphurization applications.

This desulphurization pump can be used to transfer a limestone slurry mixture, discharge a gypsum slurry mixture, feed mixtures into a filter, enable the slurry to circulate in the absorber tower, and recycle the slurry mixture. It is a single-stage, single-suction, and horizontal pump available with a cylindrical-shaped cantilever. Its casing and vanes are made of high-chromium cast iron for abrasion and wear resistance. The bearing is lubricated with thin oil, as is shown in the following picture. The shaft seal adopts the double end-face mechanical seal to prevent leakage and ensure a prolonged service life.

Available with an axial-flow impeller, our centrifugal desulphurization pump allows fluid to enter the pump from only one side. In its abrasion- and corrosion-resistant body, the pump houses many attributes that are commonly found in other similar domestic and foreign products. It is an innovative design that delivers high energy efficiency, abrasion- and wear-resistance, little noise, low abrasion, reliable functioning, and long service life. With unsurpassed overall performance, the product has soon gained popularity in thermal power plant, aluminum smelting plant, and oil refinery, where it is used in desulphurization system to transport limestone or gypsum slurry.

Our pump is able to serve in various conditions where mass concentration is up to 60%, chloride ion concentration as high as 60000ppm, PH value between 2.5 and 13, or slurry temperature close to 65℃.

| Diagram | Structure |

| 1. Volute casing2. Impeller3. Rear Wear Liner4. Supporting Bracket5. Left Supporting Board6. Bearing Cartridge7. Motor Support8. Drainage Pipe9. Right Supporting Board |

Purchase Order Number

1. Example: 50ZTL-40B

2. 50: pump outlet diameter (mm)

3. Z: slurry pump

4. T: desulphurization

5. L: floor-standing (submerged)

6. 40: vane diameter (cm)

7. B: number of vanes (4); A-5(omissible), B-4, C-3, F-6, G-7, H-8

| Model | Maximum Operating Power (KW) | Volumetric Flow Rate Q(m3/h ) | Total Dynamic Head H(m) | Rotational Speed n(r/m) | Maximum Efficiency η( %) | Maximum Granularity of Particles (mm) | Pump Weight (kg) |

| 150ZTL-35 | 30 | 99-364 | 3.0-17.9 | 490-980 | 69.0 | 15 | 800 |

| 100ZTL-34 | 45 | 74-293 | 5.5-36.8 | 700-1480 | 65.8 | 14 | 630 |

| 80ZTL-45 | 110 | 59-286 | 12.5-81.6 | 700-1490 | 58.4 | 15 | 680 |

| 80ZTL-36 | 45 | 50-201 | 7.3-45.5 | 700-1480 | 58.2 | 12 | 650 |

| 65ZTL-30 | 18.5 | 18-98 | 5.9-34.7 | 700-1470 | 53.7 | 8 | 440 |

| 50ZTL-40B | 30 | 15-65 | 8.6-58.3 | 34.1 | 9 | 540 | |

| 50ZTL-35 | 22 | 19-86 | 7.3-47.1 | 48.1 | 15 | 500 | |

| 50ZTL-20 | 4 | 8-38 | 1.4-10.7 | 700-1440 | 38.6 | 10 | 240 |

| 40ZTL-35 | 18.5 | 9.4-47.6 | 8.1-48.0 | 700-1470 | 38.7 | 7 | 500 |

| 40ZTL-25B | 5.5 | 4.9-22.9 | 3.9-21.5 | 700-1440 | 37.6 | 8 | 225 |

| 40ZTL-A21 | 4 | 4.6-25.9 | 3.3-17.0 | 44.6 | 10 | 210 | |

| 25ZTL-15 | 5.5 | 4.3-19.3 | 3.9-30.8 | 1390-2900 | 29.8 | 8 | 176 |

Related Names

Viscous Liquid Pump | Industrial Slurry Pump | Positive Discharge Pump

Links:https://www.globefindpro.com/products/86398.html

-

Biscuit Stacker

Biscuit Stacker

-

ZJL Series Vertical Centrifugal Slurry Pump for Mining and Electric Power Industry

ZJL Series Vertical Centrifugal Slurry Pump for Mining and Electric Power Industry

-

Mobile Air Compressor

Mobile Air Compressor

-

Coal Bed Gas Screw Compressor

Coal Bed Gas Screw Compressor

-

CNG Compressor

CNG Compressor

-

Oil Free Compressor

Oil Free Compressor

-

Rotary Moulder

Rotary Moulder

-

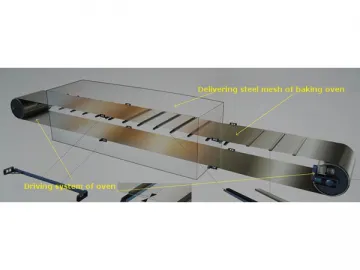

Driving System for Oven Band

Driving System for Oven Band

-

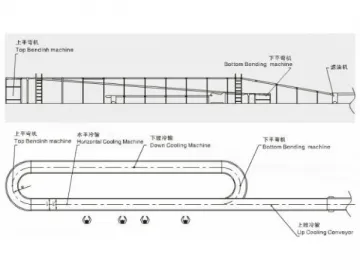

Cooling Conveyor

Cooling Conveyor

-

Vertical Dough Mixer

Vertical Dough Mixer

-

Dough Laminator

Dough Laminator

-

ZG(P) Series Centrifugal Slurry Pump for Gold Mining and Metallurgy Industry

ZG(P) Series Centrifugal Slurry Pump for Gold Mining and Metallurgy Industry