ZTX(R) Series Single-Stage Single-Suction Horizontal Centrifugal Desulfurization Pump

The ZTX(R) series single-stage single-suction horizontal centrifugal desulphurization pump is primarily used in the absorber tower of FGD plant. Highly energy-efficient and easy to repair, the pump has a relatively large discharge at a low head. Available also with a compact X-bracket, the pump takes up very little floor space.

Flue-gas desulphurization can be a dangerous process given the various abrasive and corrosive conditions involved. Hence, we've carefully developed a state of the art material used to construct a pump that is specifically intended for the FGD plant. The material combines the corrosion resistant characteristics of the duplex stainless steel with the abrasion resistant features of the high-chromium cast iron. This allows the pump to have improved resistance to abrasion and corrosion.

With the aid of CFD design tool, pumping parts can be precisely designed to offer the maximum reliability and efficiency. Pump's rear casing can be removed to allow easy repair, without the need to take apart the inlet and outlet duct. The pump end utilizes two-row tapered roller bearings while the pump drive shaft is provided with cylindrical roller bearings. Thin oils are used to lubricate these bearings to improve their operating conditions as well as prolong their use life.

The location of vanes inside the desulphurization pump casing can be changed via adjusting the bearing assembly. Flexibility in vane re-arrangement around the circumference of the shaft allows the pump to maintain in a highly-efficient operating state. Cartridge seal is used to add reliability to pump operation. This seal is specially designed to suit flue-gas desulphurization application.

Features

1. Our desulphurization pump comes with two casings. Inside the inner casing, there are replaceable liners made of hardened alloy or rubber to deliver reliability and high resistance to abrasion and corrosion.

2. The rear casing can be removed to allow easy pump inspection, repair, and vane and mechanical seal replacement, without the need to take apart the inlet and outlet ducts.

3. Highly-efficient hardened alloy vane.

4. Oil-lubricated bearing installation with high load carrying capacity.

5. Cartridge seal enables the pumping parts to have a long service life with limited maintenance.

6. This series of desulphurization pump can be directly coupled with the drive motor.

Advantages

1. Consumable parts have a long service life.

2. Prolonged use life of bearing and mechanical seal

3. Ease of maintenance

4. Low operating cost

5. High reliability

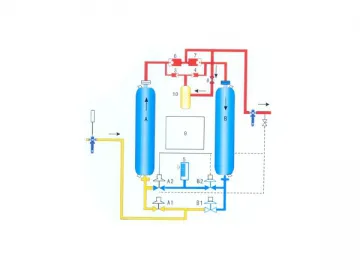

| Diagram | Structure | |

Purchase Order Number

Example: 350ZTX(R)

350: pump outlet diameter (mm)

Z: slurry pump

T: desulphurization

X: bracket

R: rubber

| Model Number | Volumetric Flow Rate Q (m3/h) | Total Dynamic Head H (m) | Rotational Speed n (r/min) | Maximum Efficiency η (%) | Net Positive Suction Head (m) | Outlet Diameter (mm) | Inlet Diameter (mm) |

| 350ZTX(R) | 1600 | 25 | 960 | 82 | 4.5 | 350 | 400 |

| 400ZTX(R) | 2500 | 25 | 725 | 83 | 5.0 | 400 | 450 |

| 500ZTX(R) | 3750 | 25 | 725 | 85 | 5.0 | 500 | 500 |

| 600ZTX(R) | 6300 | 25.5 | 620 | 88 | 5.5 | 600 | 700 |

| 700ZTX(R) | 6840 | 26 | 485 | 87 | 6.0 | 700 | 800 |

| 800ZTX(R) | 9360 | 31 | 485 | 90 | 7.0 | 800 | 900 |

| 900ZTX(R) | 15000 | 30 | 485 | 90 | 8.5 | 900 | 1000 |

| 1000ZTX | 10440 | 15 | 485 | 89 | 7.0 | 1000 | 1200 |

Related Names

Inline Pump | Low Flow Centrifugal Pump | Flue Gas Desulphurization Pump

Links:https://www.globefindpro.com/products/86406.html

-

Combined Screw Compressor and Booster

Combined Screw Compressor and Booster

-

SBY Heated Desiccant Dryer

SBY Heated Desiccant Dryer

-

ZGYX-451 Hydraulic DTH Drilling Rig

ZGYX-451 Hydraulic DTH Drilling Rig

-

Atlas Copco Hydraulic Drilling Rig

Atlas Copco Hydraulic Drilling Rig

-

ZGJ Pump Mechanical Seal

ZGJ Pump Mechanical Seal

-

ZHJ Pump Mechanical Seal

ZHJ Pump Mechanical Seal

-

Compressed Air Tank

Compressed Air Tank

-

Oil Free Compressor

Oil Free Compressor

-

CNG Compressor

CNG Compressor

-

Coal Bed Gas Screw Compressor

Coal Bed Gas Screw Compressor

-

Mobile Air Compressor

Mobile Air Compressor

-

ZJL Series Vertical Centrifugal Slurry Pump for Mining and Electric Power Industry

ZJL Series Vertical Centrifugal Slurry Pump for Mining and Electric Power Industry