Combined Screw Compressor and Booster

As the name indicates, the combined screw compressor and booster is an integral package that combines the functions of both reciprocating screw compressor and booster compressor. It is able to offer high pressure compressed air for use in PET bottle blowing, molding, leak testing and more fields, and is an economical replacement of conventional high pressure air compressors.

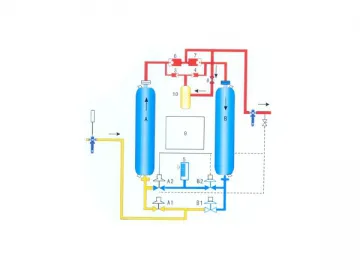

The compressed air processed by the screw air compressor is transmitted to the booster for a second compression, and then the outlet pressure will be as high as 4.0Mpa. The combined screw compressor and booster is able to produce qualified compressed air without oil or water, which is critical to bottle blowing industry. This compressed air equipment is popular in the world and easier than other systems. Moreover, the screw booster is remarkable for reliable air feed performance, easy operation and simple maintenance.

Features of the Combined Screw Compressor and Booster

1. Low Noise and Stable Air Feed Performance

The screw compressor is of good reliability and less noise, since it connects to the booster with enclosed pipes.

2. Integrated System

The whole system is composed of a screw compressor, a booster, and the air storage and cleaning system. The combined screw compressor and booster is skid mounted, and its reasonable structure can maximally save space and increase the flexibility of equipment installation.

3. High-quality Compressed Air Without Oil or Water

The combined air compression system is able to purify air, and makes sure that the residual oil amount of the compressed air is less than or equals to 0.001PPM, and the atmospheric dew point is 23℃.

4. The miniwatt screw compressor adopts the unique air-cooling technology, instead of complex water-cooling, because the air cooling method can be applied in a wide range and avoid limescale and water pollution. It helps you to save cost, conserve resources and protect environment.

5.The advanced intelligent microcomputer technology thoroughly changes the traditional instrument control mode. To be specific, every key point is fitted with various sensors to display the machine state on the screen in real time. The actuator is reduced to a solenoid valve, which improves reliability, reduces fault points and cuts operating costs. Moreover, the combined screw compressor and booster contains the gas capacity automatic adjustment, guarding in turn, coordination function and running length control function when a failure occurs, so as to guarantee safety and improve productivity.

Parameters of the Combined Screw Compressor and Booster

| Model and name | Gas displa-cement(m3/min) | Inlet pres-sure (Mpa) | Disch-arge pressure (Mpa) | Type and stage | Lubri-cation method | Cooling method | Para-meter of motor | Dimension (L*M*H) | Weight (KG) | No-tes |

| LG.V-8/100 | 8 | 0 | 10 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 132KW/380V | 5000*2500 *1850 | 6000 | |

| LG.V-10/100 | 10 | 0 | 10 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 160KW/380V | 5000*2500 *1850 | 8000 | |

| LG.V-15/100 | 15 | 0 | 10 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 220KW/380V | 5000*2500 *1850 | 8500 | |

| LG.V-20/100 | 20 | 0 | 10 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 315KW/380V | 5000*2500 *1850 | 10000 | |

| LG.V-30/100 | 30 | 0 | 10 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 450KW | 6500*2500 *2000 | 15000 | 6KV/ 10KV |

| LG.M-40/100 | 40 | 0 | 10 | Twin screw, M type, three-stage | Oil injection | Water cooling/ Mixed cooling | 630KW | 7000*2500 *2200 | 16000 | 6KV/ 10KV |

| LG.M-50/100 | 50 | 0 | 10 | Twin screw, M type, three-stage | Oil injection | Water cooling/ Mixed cooling | 710KW | 7000*2500 *2400 | 18000 | 6KV/ 10KV |

| LG.V-8/150 | 8 | 0 | 15 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 132KW/380V | 5000*2500 *1850 | 8000 | |

| LG.V-10/150 | 10 | 0 | 15 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 185KW/380V | 5000*2500 *1850 | 8000 | |

| LG.V-15/150 | 15 | 0 | 15 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 250KW/380V | 5000*2500 *1850 | 8500 | |

| LG.V-20/150 | 20 | 0 | 15 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 355KW/380V | 7000*2500 *1850 | 10000 | |

| LG.M-30/150 | 30 | 0 | 15 | Twin screw, M type, three-stage | Oil injection | Water cooling/ Mixed cooling | 500KW | 7000*2500 *2200 | 16000 | 6KV/ 10KV |

| LG.V-8/250 | 8 | 0 | 25 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 160KW/380V | 5000*2500 *1850 | 8000 | |

| LG.V-10/250 | 10 | 0 | 25 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 185KW/380V | 5000*2500 *1850 | 8000 | |

| LG.V-15/250 | 15 | 0 | 25 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 280KW/380V | 5000*2500 *1850 | 8500 | |

| LG.V-20/250 | 20 | 0 | 25 | Twin screw, V type, three-stage | Oil injection | Water cooling/ Mixed cooling | 400KW/380V | 6000*2500 *2000 | 15000 | |

| LG.V-8/350 | 8 | 0 | 35 | Twin screw, V type, four-stage | Oil injection | Water cooling/ Mixed cooling | 160KW/380V | 5000*2500 *1850 | 8000 | |

| LG.V-10/350 | 10 | 0 | 35 | Twin screw, V type, four-stage | Oil injection | Water cooling/ Mixed cooling | 200KW/380V | 5000*2500 *1850 | 8000 | |

| LG.V-15/350 | 15 | 0 | 35 | Twin screw, V type, four-stage | Oil injection | Water cooling/ Mixed cooling | 280KW/380V | 5000*2500 *1850 | 8500 | |

| OG.V-20/350 | 20 | 0 | 35 | Single screw, V type, four-stage | Oil injection | Water cooling/ Mixed cooling | 415KW/380V | 5000*2500 *1850 | 8500 | |

| LG.V-8/400 | 8 | 0 | 40 | Twin screw, V type, four-stage | Oil injection | Water cooling/ Mixed cooling | 185KW/380V | 5000*2500 *1850 | 8000 | |

| LG.V-10/400 | 10 | 0 | 40 | Twin screw, V type, four-stage | Oil injection | Water cooling/ Mixed cooling | 200KW/380V | 5000*2500 *1850 | 8000 | |

| LG.V-15/400 | 15 | 0 | 40 | Twin screw, V type, four-stage | Oil injection | Water cooling/ Mixed cooling | 315KW/380V | 5000*2500 *1850 | 8500 | |

| OG.V-20/400 | 20 | 0 | 40 | Single screw, V type, four-stage | Oil injection | Water cooling/ Mixed cooling | 415KW/380V | 5000*2500 *1850 | 8500 |

Links:https://www.globefindpro.com/products/86407.html

-

SBY Heated Desiccant Dryer

SBY Heated Desiccant Dryer

-

ZGYX-451 Hydraulic DTH Drilling Rig

ZGYX-451 Hydraulic DTH Drilling Rig

-

Atlas Copco Hydraulic Drilling Rig

Atlas Copco Hydraulic Drilling Rig

-

ZGJ Pump Mechanical Seal

ZGJ Pump Mechanical Seal

-

ZHJ Pump Mechanical Seal

ZHJ Pump Mechanical Seal

-

ZGYX-430BD Pneumatic DTH Drilling Rig

ZGYX-430BD Pneumatic DTH Drilling Rig

-

ZTX(R) Series Single-Stage Single-Suction Horizontal Centrifugal Desulfurization Pump

ZTX(R) Series Single-Stage Single-Suction Horizontal Centrifugal Desulfurization Pump

-

Compressed Air Tank

Compressed Air Tank

-

Oil Free Compressor

Oil Free Compressor

-

CNG Compressor

CNG Compressor

-

Coal Bed Gas Screw Compressor

Coal Bed Gas Screw Compressor

-

Mobile Air Compressor

Mobile Air Compressor