ZGYX-450 Hydraulic DTH Drilling Rig

The ZGYX-450 hydraulic DTH drilling rig is designed for highway, railway, mine, hydroelectric power station and other engineering construction.

This hydraulic drilling machine features fast speed, less oil consumption, good gradeability, low cost and easy maintenance.

Main Technical Parameters of the Hydraulic DTH Drilling Rig

Range of bore diameter: ¢115-152mm

Drill pipe specification: 89/102mm×4M

Drill rod for punching: 89/102*3.4M

Capability of drill rod changing device: 6 1 ; Drilling depth: 28M

Recommended impactor: 4" or 5"; Rotating speed: 0-105r/min

Rotary torque: 4045N*M

Diesel Engine for the Drilling Equipment

Steyr D10.36T20

Rated power (when 2200rpm): 266KW ; Fuel capacity: 580L

Air Compressor for the Down the Hole Drilling Rig

Equipped air compressor: (Made by CompAirs)

Head of air compressor: Germany GHH

Rated working pressure of air compressor: 17bar

Displacement of air compressor: 18 m³/min

Drilling Arm for the DTH Drilling Rig

Type of drilling arm: Single straight arm

Propulsion mode: Hydro-cylinder wire rope type

Overall length of propulsion beam: 8100mm ; Propulsion stroke: 4600mm

Propulsion compensation: 1200mm ; Max. propelling speed: 0.88m/s

Max. propulsion: 34.5KN ; Max. drawing force: 67.6KN

Swinging angle: -10°~ 30°

Adjustable angle: 1100mm -3100mm

Angular adjustment: Arbitrary 0~90° ; Pitching angle: -15°~ 90°

Tilt angle: -5° ~ 90°

Chassis for the Hydraulic Drilling Rig

Max. travel speed: 3km/h ; Driving force: 117.7KW

Max. gradeability: 25° ; Oscillation angle of truck frame: ±10°

Ground clearance: 420mm

Hydraulic System for the Drilling Machine

The hydraulic system consists of the variable pump and proportioning valve. Each motion is continuously adjustable. Its integrated control system for drilling parameters supports real time adjustment and ensures high efficiency and low consumption.

Electrical System for the Rotary Drilling Rig

It offers several functions, such as real-time display, dynamic monitoring, fault diagnosis, operation interlocking, maintenance prompting, original record saving, etc.

Gas Path System for the Drilling Rig

The gas path system of the integrated hydraulic DTH drilling rig can switch between high and low pressure, and adopts automatic air flow adjustment.

Transportation Size

Width: 2500mm Length: 10260mm Height: 2900mm

Weight (excluding optional accessories): 21000kg

Standard Parts of the Hydraulic DTH Drilling Rig

1. Air-conditioned cab that is able to prevent turnover and withstand rock-fall

2. Automatic rod changing device assembly

3. Double hydraulic pressure tool for holding drill rod

4. Double speed travel motor

5. Dry-type dust collection system assembly

6. Decompressing punching device

7. Moveable dust collecting cover

8. Heavy crawler-type chassis

9. Common tools and accessories

Optional Parts of the Hydraulic DTH Drilling Rig

1. Automatic device for preventing sticking

2. Wet-type dust catcher

3. Pre-heating unit of diesel engine

4. Intelligent control system

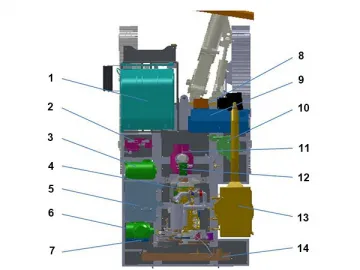

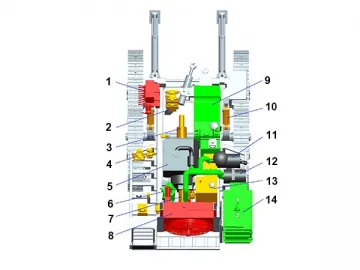

Interior Parts of the Hydraulic DTH Drilling Rig

| 1. Cab2. Valve module3. Air filter of air compressor4. Yuchai A35F0 diesel engine5. Hydraulic oil tank6. Air filter of diesel engine7. Diesel preheater8. Atomized lubricator9. Diesel tank10. Oil gas keg11. Screw machine12. Independent gear case13. Dust catcher14. Cooler assembly |

Links:https://www.globefindpro.com/products/86425.html

-

High Pressure Breathing Air Compressor

High Pressure Breathing Air Compressor

-

Low Pressure Screw Compressor

Low Pressure Screw Compressor

-

LG10-LG50 Screw Compressor

LG10-LG50 Screw Compressor

-

D, DG Series Multistage Water Pump

D, DG Series Multistage Water Pump

-

Mobile Diesel Air Compressor

Mobile Diesel Air Compressor

-

S, SH Series Double-Suction Water Pump

S, SH Series Double-Suction Water Pump

-

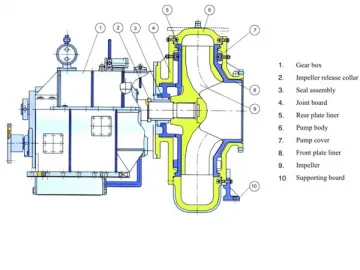

PNJ Series Rubber Mud Pump

PNJ Series Rubber Mud Pump

-

WQ Series Submersible Sewage Pump

WQ Series Submersible Sewage Pump

-

ZGYX-520 Top Hammer Drill

ZGYX-520 Top Hammer Drill

-

ZN Series Horizontal Single Stage Centrifugal Dredge Pump

ZN Series Horizontal Single Stage Centrifugal Dredge Pump

-

QJ Series Submersible Pump

QJ Series Submersible Pump

-

ZLR Series Vertical Rubber Centrifugal Slurry Pump for Coal Washery

ZLR Series Vertical Rubber Centrifugal Slurry Pump for Coal Washery