Centrifugal Air Compressor

Introduction of the Centrifugal Air Compressor

1. With an integrated design, the centrifugal air compressor is easy for maintenance.

2. The main oil pump connects to the main shaft through a coupling joint, so it is easy to replace them.

3. The reliable sealing system makes sure that the industrial air compressor produces oilless compressed air. Its grease system is able to protect lubricant from pollution, so as to reduce the probability of halt.

4. The built-in auxiliary equipment provides the centrifugal air compressor with simplified installation procedure.

5. To guarantee the lubrication of the gear case, the self-sustained pressure lubrication system comprises a main oil pump and an auxiliary one. Thus, the centrifugal compressor features reliable performance, failure-free operation, less vibration and low noise.

Features of the Centrifugal Air Compressor

1. The centrifugal air compressor adopts the compact structure, leading core technology, high-powered impeller, shaft seal and vibration detection, regulating mechanism, tilting-pad bearing, rough grade bevel wheel and thrust ring.

2. All the parameters can be displayed on a touch screen to show the working condition. Thus, the operator can easily control the industrial compressor. If a failure occurs, the screen will show the reason and solution. The historical data of the centrifugal air compressor are stored for your reference.

3. The gear case, pinion bearing, bull wheel bearing and sealing element all belong to horizontal-split type. After removing the cover of the gear case, the sealing element, bearings and gears can be examined and repaired directly.

8. All the main parts for the centrifugal compressor including the gear, intercooler, aerodynamic components, lubrication system and control system are highly integrated and easy to repair independently, which greatly facilitates failure checking and maintenance inspection.

9. The straight-through type intercooler of the centrifugal air compressor may be cleaned easily.

10. It is unnecessary to make dynamic and static balance adjustment again after the operator removes and remount the rotor.

11. Due to its simple and clear operation options, the advanced microelectronic control system is easy to use. It monitors flow, pressure, temperature and vibration values in real time, performs various control functions, and ensures safe and normal operation of the compressed air equipment.

Technical Parameters of the Centrifugal Air Compressor

| Model | Rated gas displacement (m3/min) | Rated discharge pressure (MPa) | Rated power of motor (KW) | Dimension (L×W×H) (mm) |

| KCC100-9 | 100.0 | 0.8 | 600 | 4500×2000×3600 |

| KCC100-11 | 100.0 | 1.0 | 700 | |

| KCC120-9 | 120.0 | 0.8 | 700 | |

| KCC120-11 | 120.0 | 1.0 | 800 | |

| KCC140-9 | 140.0 | 0.8 | 900 | |

| KCC140-11 | 140.0 | 1.0 | 900 | |

| KCC160-9 | 160.0 | 0.8 | 1000 | |

| KCC160-11 | 160.0 | 1.0 | 1000 | |

| KCC180-9 | 180.0 | 0.8 | 1000 | 5000×2100×3600 |

| KCC180-11 | 180.0 | 1.0 | 1100 | |

| KCC215-9 | 215.0 | 0.8 | 1200 | |

| KCC215-11 | 215.0 | 1.0 | 1300 | |

| KCC250-9 | 250.0 | 0.8 | 1400 | |

| KCC250-11 | 250.0 | 1.0 | 1500 |

Links:https://www.globefindpro.com/products/86455.html

-

Proportional Hydraulic Trainer

Proportional Hydraulic Trainer

-

Servo Hydraulic Trainer

Servo Hydraulic Trainer

-

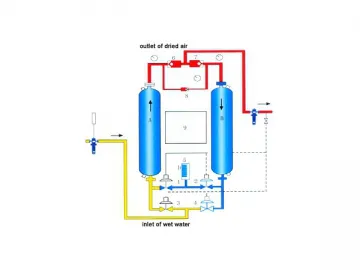

SBX Heatless Desiccant Dryer

SBX Heatless Desiccant Dryer

-

Ingersoll Rand Centrifugal Compressor

Ingersoll Rand Centrifugal Compressor

-

Basic Hydraulic Training System

Basic Hydraulic Training System

-

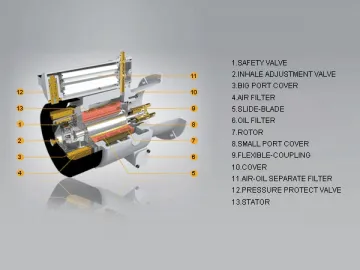

Sliding Vane Compressor

Sliding Vane Compressor

-

Force, Pressure and Temperature Sensor Trainer

Force, Pressure and Temperature Sensor Trainer

-

MCU Training and Testing Device

MCU Training and Testing Device

-

Atlas Copco Pneumatic Drilling Rig

Atlas Copco Pneumatic Drilling Rig

-

Liquid CO2 Tank

Liquid CO2 Tank

-

Distance, Displacement Sensor Trainer

Distance, Displacement Sensor Trainer

-

Ingersoll Rand Stationary Screw Compressor

Ingersoll Rand Stationary Screw Compressor