Sliding Vane Compressor

As one of our special types of industrial air compressor, the SL series sliding vane compressor simplifies its appearance, brings down the overall cost and increases price-performance ratio. With open-type structure, the rotary vane air compressor is easy for maintenance, and the control panel is so simple that a green hand may know how to operate.

Major Features of the Sliding Vane Compressor

1. Low Maintenance Cost

The maintenance only requires the operator to change oil, clean or replace the air filter and clean the radiator according to the interval set in advance. The oil content core can be replaced every 8-10 thousand working hours, which ensures extremely low maintenance cost of the rotary sliding vane compressor.

2. Automatic Air Supply

In order to reduce unnecessary pressure loss, the servo valve at the inlet is designed on the basis of maximum flow. Once the sliding vane air compressor is full load, the air suction valve will completely open. As the air demand declines, the internal pressure will rise and the servo valve will gradually close its inlet valve, so as to adjust gas output and satisfy various requirements. In that way, your consumed energy may equal to required energy, which can avoid wasting, save energy and lower cost.

3. Integrated Compression Unit

The oil chamber, separator, check valve, servo valve, vacuum valve and oil filter are integrated within the sliding vane compressor, to make it more compact.

4. Durability

This range of industrial compressor comes with less abrasion, low noise and slow rotational speed of only 1480r.p.m, which guarantees longer service life.

5. Electric Energy of Fan

Different from a common air compressor adopting an independent motor for its cooler, our rotary sliding vane compressor uses the main motor to drive both the air compressor and the cooling fan, so as to cut down power consumption and reduce failure probability.

6. Reliability

Under ordinary pressure, our sliding vane compressor is able to work round the clock throughout the year, with the operating time of over 100 thousand hours.

7. Noise

The gas compressor noise is low enough to meet the related specifications.

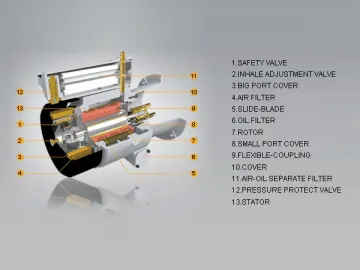

Operating Principle of the Sliding Vane Compressor

Processed by an air filter, the air is transmitted to the rotary sliding vane compressor through an air suction valve. The valve is able to adjust the air demand in the air compressor in accordance with different requirements, so as to remain stable working pressure.

The rotor eccentrically rotates in the stator. There are vertical slots on the surface of the rotor. Sliding vanes are placed in the slot, and close to the inwall of the stator due to centrifugal force. Then, the stator, rotor, and sliding vanes form the empty chamber-compression chamber, where air is compressed.

In the process of compression, lubricating and cooling are completed by an efficient oil-injection system. The system makes sure the rotary vane air compressor can effectively control the process with low lubricant consumption. The oil slick on the inwall of the rotor prevents the contact between metal parts and avoid wearing. When the rotor is rotating, the volume of the compression chamber formed by two adjacent sliding vanes and the stator decreases, so as to fulfill compression. After multiple separation, the sliding vane compressor offers compressed gas-oil mixture with low oil content that is under 1.5ppm. The separated clear air will be processed by a compressed air cooler, and any condensate water generated may be discharged by a draw off valve.

| 1. Air filter | 2. Automatic air inlet | 3. Oil system | 4. Compression chamber |

| 5. Oil cooler | 6. Oil filter | 7. Maze structure | 8. Compressed air |

| 9. Rotor | 10. Oil-gas separator | 11. Oil return valve | 12. Min. pressure valve |

| 13. Oil inlet tube | 14. Oil outlet tube | 15. Admission pipe | 16. Escape pipe |

| 17. Cooler | 18. Fan | 19. Air-water separator | 20. Solenoid drain valve |

Technical Parameters of the Sliding Vane Compressor

| Model | Rated flow (m3/min) | Power of main motor (KW) | Dimension (mm) | Noise dB(A) | Size of air outlet (in.) | Weight (Kg) | |||

| 8bar | 10bar | Length | Width | Height | |||||

| SL-05 | 0.82 | 0.7 | 5.5 | 1230 | 440 | 760 | 65 | Rp3/4 | 198 |

| SL-07 | 1.2 | 1 | 7.5 | 1330 | 480 | 760 | 65 | Rp3/4 | 204 |

| SL-11 | 1.71 | 1.5 | 11 | 1370 | 500 | 820 | 66 | Rp3/4 | 254 |

| SL-15 | 2.62 | 2.22 | 15 | 1600 | 550 | 940 | 67 | Rp1 | 385 |

| SL-18 | 3.16 | 2.59 | 18.5 | 1670 | 600 | 960 | 68 | Rp1 | 402 |

| SL-22 | 3.68 | 3.25 | 22 | 1670 | 600 | 960 | 68 | Rp1 | 435 |

| SL-30 | 5.09 | 4.25 | 30 | 1995 | 780 | 1175 | 69 | Rp1 1/4 | 688 |

| SL-37 | 6.38 | 5.29 | 37 | 2035 | 780 | 1200 | 69 | Rp1 1/4 | 748 |

| SL-45 | 7.66 | 6.27 | 45 | 2035 | 780 | 1200 | 70 | Rp1 1/4 | 810 |

| SL-55 | 10.1 | 8.1 | 55 | 2145 | 830 | 1230 | 70 | Rp2 | 950 |

| SL-75 | 12.76 | 10.58 | 75 | 2470 | 996 | 1420 | 71 | Rp2 | 1270 |

| SL-90 | 15.32 | 12.54 | 90 | 2470 | 996 | 1420 | 71 | Rp2 | 1380 |

Links:https://www.globefindpro.com/products/86461.html

-

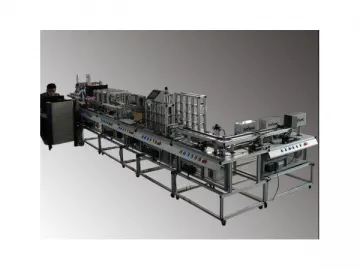

DLWL-800A Modular Logistics Production Trainer

DLWL-800A Modular Logistics Production Trainer

-

PCB Metallization Equipment

PCB Metallization Equipment

-

Complete Air Compressor Workstation

Complete Air Compressor Workstation

-

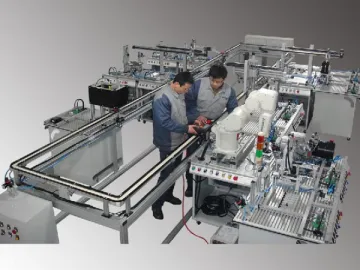

DLFMS-1601 Flexible Manufacturing System Trainer

DLFMS-1601 Flexible Manufacturing System Trainer

-

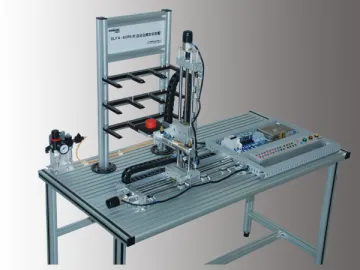

Automatic Storage and Retrieval System Training Set

Automatic Storage and Retrieval System Training Set

-

Servo Motor Trainer

Servo Motor Trainer

-

Basic Hydraulic Training System

Basic Hydraulic Training System

-

Ingersoll Rand Centrifugal Compressor

Ingersoll Rand Centrifugal Compressor

-

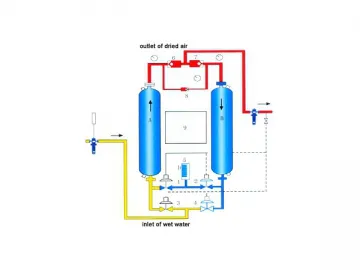

SBX Heatless Desiccant Dryer

SBX Heatless Desiccant Dryer

-

Servo Hydraulic Trainer

Servo Hydraulic Trainer

-

Proportional Hydraulic Trainer

Proportional Hydraulic Trainer

-

Centrifugal Air Compressor

Centrifugal Air Compressor