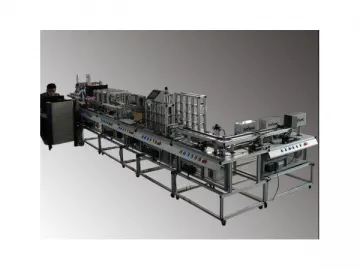

Complete Air Compressor Workstation

The LG series complete air compressor workstation is the combination of a rotary screw compressor, a refrigerated air dryer and a compressed air filter. It can release dry and clean compressed air, guarantee air quality, greatly enhance productivity and reduce the cost of production.

Performance Features of the Complete Air Compressor Workstation

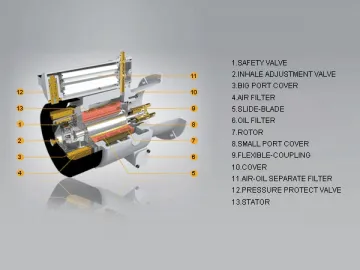

1. For proven performance of the industrial compressed air system, the screw compressor is available with reliable and efficient parts.

2. Efficient cooling system

3. Integrated oil-gas separation system

4. Compact structure and ultra low noise

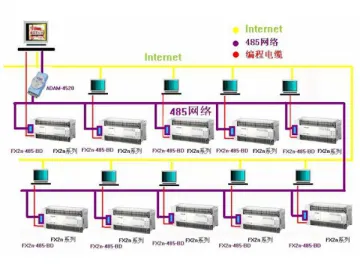

5. The coordinated control over multiple screw air compressors can be set in accordance with your requirements.

6. Owing to the advanced design, the vibration amplitude of the complete air compressor workstation is far below the international value.

7. The aluminum plate fin cooler features compact structure, light weight and great heat transfer efficiency, which enables the complete air compressor workstation to work in a high temperature environment.

Price-performance Ratio of the Complete Air Compressor Workstation

1. The complete compressed air workstation is improved to suit a wider range of working conditions.

2. The high-quality accessories are efficient enough to cut down your expenditures.

3. Due to the good design and long operating time, the compressed air system can save your maintenance cost.

4. Its EPC intelligent control system supports automatic starting or stopping the machine, and minimizes energy consumption.

5. Our complete air compressor workstation comes with small size, quick installation, high automaticity and easy operation, which maximally reduces downtime.

Technical Parameters of the Complete Air Compressor Workstation

| Model | Discharge Pressure (bar) | Volume Flow (m3/min) | Motor Power (KW) | Noise dB(A) | Pressure Dew Point (℃) | Weight (kg) | Outlet Size | Dimension L×W×H(mm) |

| LG5-7 | 7/7.5 | 0.92 | 5.5 | 63 | 3-10 | 340 | G3/4 | 1400×670×1550 |

| LG5-8 | 8/8.5 | 0.85 | ||||||

| LG5-10 | 10/10.5 | 0.65 | ||||||

| LG8-7 | 7/7.5 | 1.25 | 7.5 | 63 | 3-10 | 350 | G3/4 | 1400×670×1550 |

| LG8-8 | 8/8.5 | 1.20 | ||||||

| LG8-10 | 10/10.5 | 1.05 | ||||||

| LG8-12.5 | 12/12.5 | 0.85 | ||||||

| LG11-7 | 7/7.5 | 2.05 | 11 | 64 | 3-10 | 520 | G3/4 | 1650×800×1840 |

| LG11-8 | 8/8.5 | 1.88 | ||||||

| LG11-10 | 10/10.5 | 1.65 | ||||||

| LG11-12.5 | 12/12.5 | 1.28 | ||||||

| LG15-7 | 7/7.5 | 2.90 | 15 | 65 | 3-10 | 580 | G3/4 | 1650×800×1840 |

| LG15-8 | 8/8.5 | 2.70 | ||||||

| LG15-10 | 10/10.5 | 2.30 | ||||||

| LG15-12.5 | 12/12.5 | 1.90 | ||||||

| LG18-7 | 7/7.5 | 3.20 | 18.5 | 66 | 3-10 | 620 | G1 | 1650×800×1840 |

| LG18-8 | 8/8.5 | 2.90 | ||||||

| LG18-10 | 10/10.5 | 2.70 | ||||||

| LG18-12.5 | 12/12.5 | 2.20 | ||||||

| LG22-7 | 7/7.5 | 3.70 | 22 | 68 | 3-10 | 650 | G1 | 1650×800×1840 |

| LG22-8 | 8/8.5 | 3.50 | ||||||

| LG22-10 | 10/10.5 | 3.20 | ||||||

| LG22-12.5 | 12/12.5 | 2.70 |

Notes

1. Power supply: 380V/3/50HZ

2. Starting mode: Star triangle step-down startup

3. Pressure dew point is tested under reference condition, namely the environment temperature of 25℃ and the pressure of 7bar.

4. Special power supply is open to reservation.

Optional Parts

1. There are two kinds of optional compressed air filters that can be installed on the LG-D machine with a dryer.

2. The LG-T series complete air compressor workstation with an air tank supports one kind of filter.

3. The US-DT with a compressed air dryer and an air tank can be fitted with two optional filters.

4. The 5kw-7kw type industrial compressed air system can be equipped with a 2.6m3/min dryer, a 250L air tank, and a T29C ultrafilter.

5. The 11kw-22kw series can be applied in conjunction with a 3.8m3/min compressed air dryer, a 360L air tank and a T38C ultrafilter.

Links:https://www.globefindpro.com/products/86464.html

-

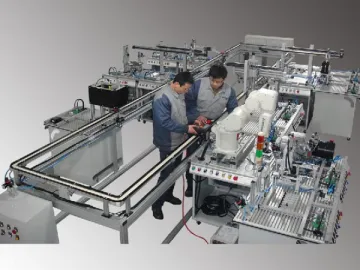

DLFMS-1601 Flexible Manufacturing System Trainer

DLFMS-1601 Flexible Manufacturing System Trainer

-

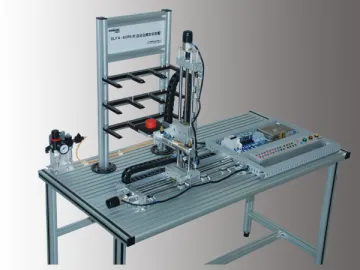

Automatic Storage and Retrieval System Training Set

Automatic Storage and Retrieval System Training Set

-

Servo Motor Trainer

Servo Motor Trainer

-

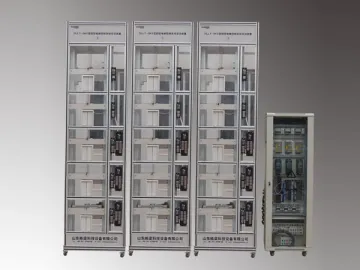

Electrical Technology Training set

Electrical Technology Training set

-

Three Sets Group Control Elevator Trainer

Three Sets Group Control Elevator Trainer

-

Industrial Automatic Control Trainer

Industrial Automatic Control Trainer

-

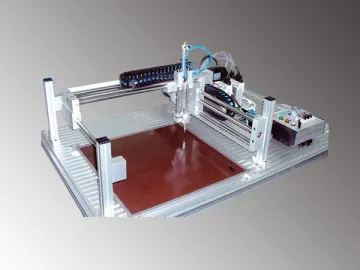

PCB Metallization Equipment

PCB Metallization Equipment

-

DLWL-800A Modular Logistics Production Trainer

DLWL-800A Modular Logistics Production Trainer

-

Sliding Vane Compressor

Sliding Vane Compressor

-

Basic Hydraulic Training System

Basic Hydraulic Training System

-

Ingersoll Rand Centrifugal Compressor

Ingersoll Rand Centrifugal Compressor

-

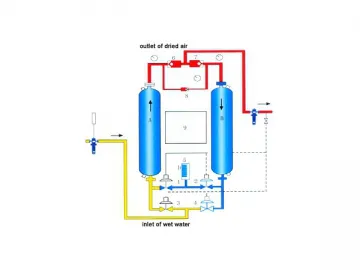

SBX Heatless Desiccant Dryer

SBX Heatless Desiccant Dryer