Custom Made Top Drive Drilling System

CustomMade Top Drive Drilling System

Here is a case about custom made machine, 250T(DQ40X) variable frequency top drive drilling system for inclined straight rig.

Technical Parameters of DQ40X

| Rated Load Capacity (Elevator, Main Shaft ) | 2250kN / 250ton |

| Rated Drilling Torque(continuous) | 31kN·m / 22800Ib·ft (≤ 95r/min) |

| Maximum Torque of Break Out | 53kN·m / 39000Ib·ft (short time ≤ 1min) |

| Maximum Torque of Brake | 45kN·m / 33100Ib·ft |

| Main Shaft Rotary Speed (stepless ) | 0~191r/min |

| Backup Tong Range | 2 7/8~6 5/8in. |

| Hydraulic System Working Pressure | 16Mpa / 2280PSI |

| Working Voltage of Explosion-proof Solenoid Valve | 24V DC |

| Rated Power of Main Motor r | 315kW / 420hp |

| Power Supply of VFD | 600V AC / 50Hz |

Features

1. The custom made machine, 250T variable frequency top drive drilling system,also called DQ40X, is designed for inclined straight rig and it is capable ofhandling special working conditions of inclined straight well. Besides, itaccords with the size of guide rail of the rig and the drilling unit is singledrill pipe. Our machine has back redressing function, and it is able to rotatethe drilling tool and do mud circulation during round trip.

2. The variable frequency drive motor whose rated power is 315kW and the gear box retarder work together tomake the main shaft rotate. Siemens frequency conversion system is applied todrive the main motor and the input power supply is 600V, 50Hz. The controlsystem is supplied by the top drive manufacturer, and electrical systemreserves connector and installation position.

3. The main thrust bearing of the power swivel adopts TIMKEN thrust bearing,while others use SKF bearing

4. Double load channels are applied by the hoisting system of our variable frequency topdrive drilling system. The main thrust bearing doesn’t carryload during round trip, thus the service life is prolonged.

5. Clamping back-up tong which can be adjusted vertically by remote control isalso equipped, and the screw thread of the protecting connector is set outsidethe tong. Thus, the driller is able to observe the connection status betweenthe top drive and the joint, and it is convenient to execute thethread-identification operation by robot arm for inclined straight rig.

6. The swivel head is designed to spin for the entire round from two directionsand the link tilt mechanism is able to incline forward and swing backward, soit can help identify the thread of the casing pipe. In addition, the swivelhead has enough oil ways for the hydraulic elevator.

7. Remote controlled IBOP is equipped for the main shaft of our variable frequencytop drive drilling system to avoid potential danger.

8. The snatch blocks are set on the two sides of the main body of the machine.They work together with the guide rail to make the top drive machine move alongthe guide rail. The guide rail is supplied with the headframe.

9. The top drive machine with balance-maintaining device is connected directlywith the traveling blocks.

10. The control loop uses two Siemens PLC and the two controllers take coldredundancy technology to guarantee the safety of the system. The PLC has manyfunctions such as interlocking, monitoring and alarming. When the main PLCbreaks down, the spare one will be in charge with a cold start.

11. The ground hydraulic station with redundancy design in hydraulic pump isadopted by the hydraulic system to ensure the reliable performance and theground station is provided by the hydraulic station of the drilling rigmanufacturer. Also, the hydraulic components are supplied by Rexroth, Atos, Sun and White.

12. The power cable and control cable with obvious signs are produced by Amercable in America, and theyare equipped with explosion-proof or high protection level connector clipsupplied by Amphenol.

13. All the parameters printed on the nameplate are shown both in the metric systemand British system such as Mpa and PSI. The instruction board of the controller and the nameplate are madefrom stainless steel and the words are easy to recognize.

14. The ambient temperature of 250T variable frequency top drive drilling system ranges from -20ºC to 50ºC, and the relative humidity should be less than 90%at the temperature of 20ºC.

15. The layout of the top drive is in accordance with the traveling block, andthe traveling block is at least 200mm higher than the peak of the top drive mainbody. Meanwhile, the distance from the top of the traveling block to the lowerend of the main body (without the link) of the top drive is less than 4600mm,and the space between the well center and the back end of the top drive is720mm at the most, and the width of the top drive main body including guidingdevice is less than 1985mm.

Working Curve of DQ40X

1. Torque (kN·m)

2. Rotary Speed (RPM)

We can design and manufacture various models oftop drive equipment following customers’ request. The 250T variable frequency topdrive drilling system, DQ40X, is specially developed for inclined straight rig,and the rated load capacity is 2250kN, the rated continuous drilling torque is 31kN·m,and the maximum torque of brake is 45kN·m. This machine is able to cope withthe special working conditions of inclined straight rig, and it can be installed withthe oil derrick. The swivel head can rotate for 360º from two directions andthe link tilt equipment is designed to incline forward and backward, and theswivel head can help identify the thread of the casing pipe. Inaddition, the working temperature has a wide range, from -20ºC to 50ºC to meetdifferent working conditions. With modular design and package, our top drivedrilling system is convenient to transport and install in the field.

Related Names

Customized Drilling Rig Provider | Offshore Oil Production

Links:https://www.globefindpro.com/products/86497.html

-

Portable Digital Circuit Trainer

Portable Digital Circuit Trainer

-

Top Drive System (Offshore Drilling and Workover Use)

Top Drive System (Offshore Drilling and Workover Use)

-

Electronics Installation Training Device

Electronics Installation Training Device

-

DLMPS-800A Modular Flexible Manufacturing System Trainer

DLMPS-800A Modular Flexible Manufacturing System Trainer

-

Opto-Mechatronics Training System

Opto-Mechatronics Training System

-

500T Variable Frequency Top Drive Drilling System

500T Variable Frequency Top Drive Drilling System

-

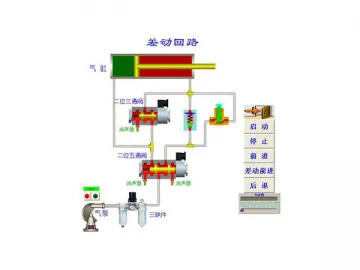

Basic Pneumatic Training System

Basic Pneumatic Training System

-

Portable PLC Training Kit

Portable PLC Training Kit

-

Electrical Safety Training Set

Electrical Safety Training Set

-

CNC Maintenance Assessment Training System

CNC Maintenance Assessment Training System

-

Frequency Converter Trainer

Frequency Converter Trainer

-

Two Sets Group Control Elevator Trainer

Two Sets Group Control Elevator Trainer