250T Variable Frequency Top Drive Drilling System

250T Variable Frequency TopDrive Drilling System

Technical Parameters of DQ40A

| Rated Load Capacity (Elevator, Main Shaft ) | 2225kN (250ton) |

| Working Height (2.7m link) | 5.12m (16.8ft) |

| Rated Drilling Torque(continuous) | 26kN·m (19100Ib·ft) |

| Maximum Torque of Break Out | 39kN·m (28700Ib·ft) |

| Maximum Torque of Brake | 47kN·m (34600Ib·ft) |

| Rotary Speed (stepless) | 0~180r/min |

| Backup Tong Range | 2 7/8~5 1/2in. |

| Rated Mud Circulating Pressure | 35Mpa (5000PSI) |

| Hydraulic System Working Pressure | 0~16Mpa (0~2280PSI) |

| Rated Power of Main Motor | 257kW (370hp) |

| Power Supply of VFD | 600V AC / 50Hz |

| Ambient Temperature | -35ºC~ 55ºC |

| Maximum Distance between Main Shaft Center and the Front End | 525×505mm |

Features

1. The drive system of 250T variable frequency top drive drilling systemadopts a variable frequency drive motor specially designed for top driveapplication, and uses ABB ACS800 frequency conversion system.

a. The stator windings of our motor own a hard winding structure and theinsulation class is H, and the current capacity is 3 times of the scatteredembedded lacquered wire under the same condition.

b. Imported FCR thin film is used for interturn insulation, and the motor is totally in the VPIwithout any solvent.

c. Our motors all employ FAG bearings and full laminative stator frame of the motor is suitable forheat dissipation and lightening the weight and volume. In addition, along withthe outside link method, the motor is also end-fixed, and the stability of themotor is improved.

d. Pressurized explosion-proof type makes the motor very safe when it isworking.

2. Besides the variablefrequency drive motor, the gear drive of our 250T variable frequency top drivedrilling system combines splash and forced lubrication together to ensure thehigh reliability and the gear box has passed relevant tests of China.

3. The hoisting system has double load channels which extends the service lifeof bearings and main shaft.

4. The pipe handling device utilizes inclining and swinging clamping back-uptong, and it is easy to change tong teeth and it protects the device from shortcircuit.

a. Link tilt mechanism is able to incline forward, swing backward and rotate,which makes the lower end of the top drive drilling machine close to the drillfloor when drilling and grabbing the drill pipe, thus the drilling tool isfully used.

b. The back-up tong doesn’t rotate with the swivel head, and there is no needto lock down the swivel head during make up and break out. Meanwhile, theclamping force is remarkable and reliable, and the maintenance of the tong isquite easy and convenient.

5. The guide rail of our 250T variable frequency top drive drilling system hasdouble-pin mechanism with a separation proof structure, and the installation ofthe guide rail is quick and easy, also the joint is very firm.

6. Accessory system is controlled by Siemens PLC, and the PLC guarantees thesafety and reliability of the system with various functions such asinterlocking, monitoring and alarm, etc.

7. The hydraulic system takes advantage of components supplied by Rexroth, SUN, and ATOS.

8. Our product uses cable which is made in China and specially designed fordrilling wells of off-shore vessels. The cable has an explosion-proof connectorand the IP rating is IP67 as shown in obvious signs. The insulator of the cableis made of no-crack rubber imported from America, and along with thehigh-pressure protecting jacket, the cable shows good resistance to high and low temperature, oil,mud, and corrosion, and the cable is well protected.

9. 250T variable frequency top drive drilling system is easy for transportationand installation due to its modular package design.

Working Curve of DQ40A

1. Torque (kN·m)

2. Rotary Speed (RPM)

Top drive drillingsystem is a new drilling system, like truck mounted drilling rig. Top drivedrilling machine shows a wide range of applications, and it can be used forwells whose depth varies from 2000m to 9000m. The rotary speed of main shaft ofour 250T variable frequency top drive drilling system is continuouslyadjustable from 0 to180r/min.The hydraulic system working pressure changes from 0 to 16Mpa, and it has anintegrated overhead type hydraulic station which is quite reliable and easy tomaintain. The hydraulic source is consisted of Siemens explosion-proof motorand Rexroth variable displacement pump, and it isonly enabled during round trip, make up, break out and directional drilling.Its swivel head and main shaft has two load channels and the swivel head hastwo ducts to supply oil to tilted oil cylinder, and the double-sealed structureof each duct makes it highly stable and reliable for applications.

Related Names

Offshore Oil Drilling Rig for Sale | High Speed Gas Extraction | Drilling Machine

Links:https://www.globefindpro.com/products/86510.html

-

350T Variable Frequency Top Drive Drilling System (Enhanced Top Drive)

350T Variable Frequency Top Drive Drilling System (Enhanced Top Drive)

-

Opto-Mechatronics Training and Assessment Device

Opto-Mechatronics Training and Assessment Device

-

Sagitar Direct Injection Engine Trainer

Sagitar Direct Injection Engine Trainer

-

Passat Electrical System Trainer

Passat Electrical System Trainer

-

Automatic Part Marking Trainer

Automatic Part Marking Trainer

-

DLMPS-900A Modular Flexible Manufacturing System Trainer

DLMPS-900A Modular Flexible Manufacturing System Trainer

-

DLMPS-600A Modular Flexible Manufacturing System Trainer

DLMPS-600A Modular Flexible Manufacturing System Trainer

-

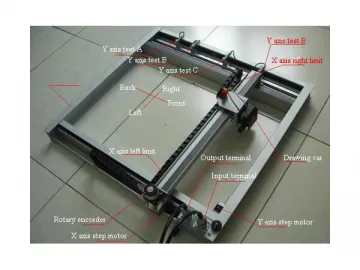

MCU Experiment and Motion Control Experiment Trainer

MCU Experiment and Motion Control Experiment Trainer

-

Portable Analogue Circuit Trainer

Portable Analogue Circuit Trainer

-

Power Electronic Automation Control Training System

Power Electronic Automation Control Training System

-

PCB Design Training Device

PCB Design Training Device

-

500T Variable Frequency Top Drive Drilling System

500T Variable Frequency Top Drive Drilling System