350T Variable Frequency Top Drive Drilling System (Enhanced Top Drive)

350TVariable Frequency Top Drive Drilling System (Enhanced Top Drive)

350T variable frequency top drive drilling system(enhanced top drive) is equipped with a variable frequencydrive motor which is specially designed for our machine, and it has SiemensG150 frequency conversion system. Hard winding structure is used for the motorstator winding, and the insulation class is H, and the high-quality FCR thinfilm is applied for turn-to-turn insulation. The over current ability is three timesof the embedded lacquered wire under the same circumstance. The motor has full laminative structure whichreduces the weight and volume and this structure does good to heat emission.Furthermore, FAG bearings are employed and the motor is in the solvent-freeVPI. Besides, it is end-fixed and outside linkmethod is also applied to improve the stability. Considering the safety, the motor is designed with pressurizedexplosion-proof function.

Technical Parameters of DQ50Ш-C

| Rated Load Capacity (Elevator, Main Shaft ) | 3150kN (350ton) |

| Working Height (3.3m link) | 5.9m (19.36ft) |

| Rated Drilling Torque(continuous) | 43kN·m(31,717Ib·ft) |

| Maximum Torque of Break Out | 65kN·m(47,944Ib·ft) |

| Maximum Torque of Brake | 53kN·m(39093Ib·ft) |

| Main Shaft Rotary Speed (stepless ) | 0~180r/min |

| Backup Tong Range | 2 7/8~5 1/2in. |

| Rated Mud Circulating Pressure | 35Mpa (5000PSI) |

| Rated Power of Main Motor | 420kW(563hp) |

| Power Supply of VFD | 600V AC / 50Hz |

| Ambient Temperature | -35ºC~ 55ºC |

| Maximum Distance between Main Shaft Center and the Front End | 526x690mm |

There are two methods of lubrication used by the gear box, splash and forcedlubrication. The efficient lubrication contributes to the reliable performanceof the gear box. Double load channels are adopted by the 350T variablefrequency top drive drilling system as well. The main shaft along with the gearbox carries load when drilling and swivel head and gear box carry load duringround trip. 7 ducts exist in the annular oil way of the swivel head, one isspare duct, and the others are used for tilt, L-type back-up tong, andhydraulic elevator. Meanwhile, L-type inclining and swinging clamping back-up tong is applied for the pipehandler, and it is convenient to change the tong teeth and it avoids shortcircuit. The elevator link is able to incline forward, swing backward androtate, which makes the lower end of the top drive close to the drill floorwhen drilling and grabbing the drill pipe, and we can use the drilling rig better.The L-type back-up tong rotates with the swivel head, and it is easy andconvenient to change the short circuit protection and up/down IBOP. Inaddition, the tong can provide reliable power, and it is facile to carry outthe maintenance.

The integrated hydraulic system adopts hydraulic components supplied by Rexroth, SUN, and ATOS, and it is on the top side.Consisted of ABB explosion-proof motor and Rexroth variable displacement pump, the hydraulic source is turned on only in theprocess of round trip, make up, break out and directional drilling. Thehydraulic system can be shut down when drilling and it gives out little heat.Also, double-pin structure with a separation-proof design is applied. 350Tvariable frequency top drive drilling system adopts China-madecable specially designed for offshore drilling. The explosion-proof connector is used and the IP rating of the cable isIP67. The insulating sheath of the cable is made of no-crack rubber produced inAmerica, which gives great protection to the cable inside. Our product isconvenient to transport and install because of the modular design.

WorkingCurve of DQ50Ш-C

1. Torque (kN·m)

2. Rotary Speed (RPM)

350T variable frequency top drive drilling system(enhanced top drive) is developed on the basis of 350T type machine. The ratedload capacity and working height of the enhanced type is the same as the 350Ttype, while the numbers are 3150kN and 5.9m, respectively. But the enhanced350T type has a higher rated continuous drilling torque of 43kN· m, and abigger maximum torque of break out whose number is 65kN· m. The assistantsystem of the enhanced 350T type is controlled by Siemens PLC, and it has manyfunctions such as interlocking, monitoring and alarming to ensure thereliability. Our machine uses AC motor and it only needs little maintenancefee. It is capable of various downhole drilling solutions, and please contact us if you want to buy this machine or have any question.

Related Names

Drilling Rig Manufacturer | Oil Well Drill Device | Exploration Equipment

Links:https://www.globefindpro.com/products/86511.html

-

Opto-Mechatronics Training and Assessment Device

Opto-Mechatronics Training and Assessment Device

-

Sagitar Direct Injection Engine Trainer

Sagitar Direct Injection Engine Trainer

-

Passat Electrical System Trainer

Passat Electrical System Trainer

-

Automatic Part Marking Trainer

Automatic Part Marking Trainer

-

DLMPS-900A Modular Flexible Manufacturing System Trainer

DLMPS-900A Modular Flexible Manufacturing System Trainer

-

150T Hydraulic Top Drive Drilling System

150T Hydraulic Top Drive Drilling System

-

250T Variable Frequency Top Drive Drilling System

250T Variable Frequency Top Drive Drilling System

-

DLMPS-600A Modular Flexible Manufacturing System Trainer

DLMPS-600A Modular Flexible Manufacturing System Trainer

-

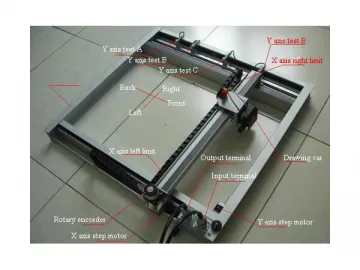

MCU Experiment and Motion Control Experiment Trainer

MCU Experiment and Motion Control Experiment Trainer

-

Portable Analogue Circuit Trainer

Portable Analogue Circuit Trainer

-

Power Electronic Automation Control Training System

Power Electronic Automation Control Training System

-

PCB Design Training Device

PCB Design Training Device