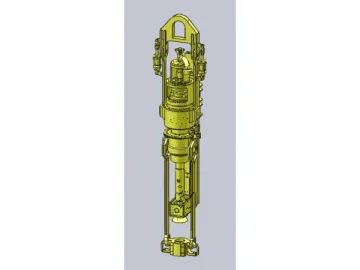

750T Variable Frequency Top Drive Drilling System

750T Variable Frequency Top Drive Drilling System

Technical Parameters of DQ90

| Rated Load Capacity (Elevator, Main Shaft ) | 6750kN (750ton) |

| Working Height (3.3m link) | 6.40m (21ft) |

| Rated Drilling Torque(continuous) | 70kN·m (51,600Ib·ft) |

| Maximum Torque of Break Out | 100kN·m (73,700Ib·ft) |

| Maximum Torque of Brake | 106kN· m (78,000Ib·ft) |

| Main Shaft Rotary Speed (stepless ) | 0~220r/min |

| Backup Tong Range | 2 7/8~5 1/2in. |

| Rated Mud Circulating Pressure | 52MPa (7540PSI) |

| Hydraulic System Working Pressure | 0~16Mpa (0~2280Psi) |

| Rated Power of Main Motor | 450kW (600hp) |

| Power Supply of VFD | 600V AC /5 0Hz |

| Ambient Temperature | -35ºC~ 55ºC |

| Maximum Distance between Main Shaft Center and the Front End | Main shaft right astern 942.5mm |

Features

The motor of 750Tvariable frequency top drive drilling system adopts full laminative stator frame which reduces the weight andvolume, and this structure is beneficial to the heat emission. Also, thehigh-quality FCR thin film is applied for turn-to-turn insulation and the motoris in the solvent-free VPI condition. Besides,the motor is end-fixed and outside link method is also applied to improve thestability. Furthermore, the motor isdesigned with pressurized explosion-proof function to avoid potential danger.

Double load channels are adopted by the 750T variable frequency top drivedrilling system. The main shaft and the gear box carry load when drilling, andswivel head and gear box carry load during round trip. There are two methods oflubrication used by the gear box which are splash and forced lubrication. Thegear box is of high reliability and has passed relevant tests in China.Besides, there are 7 ducts existing in the annular oil way of the swivel head,one is spare duct, and the others are used for tilted cylinder, L-type back-uptong, and hydraulic elevator. Meanwhile, L-type back-up tong is applied for thepipe handler of our top drive drilling system. The elevator link is able toincline forward, swing backward and rotate, which makes the lower end of thetop drive close to the drill floor when drilling and grabbing the drill pipe,and we can make full use of the drilling string. The L-type back-up tongrotates with the swivel head, and it is easy and convenient to change the shortcircuit protection, tong teeth and up/down IBOP. In addition, the tong canoutput reliable power, and it is facile to carry out the maintenance.

The integrated hydraulicsystem of 750T variable frequency top drive drilling system takes advantage ofhydraulic components produced by Rexroth, SUN, and ATOS, and it is on the topside. The hydraulic source, consisted of ABB explosion-proof motor and Rexrothvariable displacement pump, is turned on only in the process of round trip,make up, break out and directional drilling. The hydraulic pump can be shutdown when drilling and only little heat is generated by the hydraulic system.Also, double-pin structure with a separation-proof design is applied.This drilling machine uses China-made cable specially designed for offshoredrilling. The explosion-proof connectoris used and the IP rating of the cable is IP67. The insulating sheath of thecable is made of crack free rubber produced in America, which gives greatprotection to the cable inside. In addition, due to the modular design, it isconvenient to transport and install our product.

Working Curve of DQ90

1. Torque (kN·m)

2. Rotary Speed (RPM)

The drive system of 750T variable frequency top drive drilling system adopts 2variable frequency drive motors which are specially engineered for top drivemachines. This motor uses Siemens S120 frequency conversion system withspecifically designed stator windings whose insulation class is H. Under thesame condition, the current capacity is three times of the scattered embeddedenameled wire. Meanwhile, this drilling machine has a ratedcontinuous drilling torque of 70kN·m, and the maximumtorque of break out is 100kN·m, the hydraulic system working pressure can reachup to 16Mpa, and the working temperature varies from -35ºC to 55ºC. Withthe reasonable design, advanced configuration, reliable performance, and highlevel of automation, 750T variable frequency top drive drilling system canlighten the intensity of work and reduce the possibility of accident, and it isthe ideal drilling equipment for you.

Related Names

Well Drilling Facility for Sale | Safe Oil Exploitation | Oilfield Drilling Technology

Links:https://www.globefindpro.com/products/86527.html

-

316L Stainless Steel Castings

316L Stainless Steel Castings

-

Casting Bearing Block

Casting Bearing Block

-

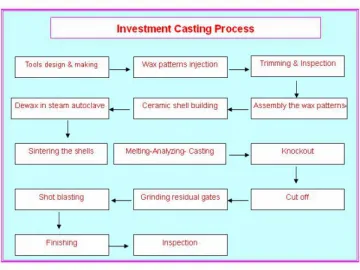

Investment Casting Process

Investment Casting Process

-

Meat Grinder Casting Parts

Meat Grinder Casting Parts

-

42CrMo Alloy Steel Casting

42CrMo Alloy Steel Casting

-

Stainless Steel Automotive Pipe fittings

Stainless Steel Automotive Pipe fittings

-

Automotive Air Conditioning Trainer

Automotive Air Conditioning Trainer

-

250T Hydraulic Top Drive Drilling System

250T Hydraulic Top Drive Drilling System

-

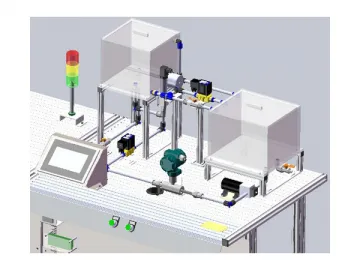

Mechanical Assembly and Debugging Training Device

Mechanical Assembly and Debugging Training Device

-

PCB Double-sided Exposure Machine

PCB Double-sided Exposure Machine

-

PLC Control System Designer Training and Testing Device

PLC Control System Designer Training and Testing Device

-

Passat Engine Trainer

Passat Engine Trainer