Investment Casting Process

Investment Casting Process

Investment casting is also known as the "lost-wax"process, is regarded as a precision casting process to fabricatenear-net-shaped metal parts from almost any alloy.

The process begins with preparation of the wax patterns forevery casting made. Wax is injected into an aluminum or steel die to produce apattern that is an exact replica of the part to be produced. The patternsare clustered around a sprue. The cluster is dippedinto a ceramic slurry made by suspending fine ceramicmaterials in silica-sol. The excess liquid is allowed to drain off frompatterns, and then fine zircon sands are stuccoed onthis ceramic coating. Thus a small shell is formed around the wax patterns. After drying, this process of dipping and stuccoing is repeated again andagain, using progressively coarser grades of ceramic material, until aself-supporting shell has been formed. It takes approximately 5 to10 days tomake the mould. When a shell thickness of approximately 6 to 10mm has been built, the molds are dewaxed by autoclaving (pressure and steam). Thisleaves a ceramic shell containing cavities of the casting shape desired withpassages leading to them. The hollow shells are then preheated to 900-1200℃,depending on the alloy to be poured and the molten metal cast immediately intothe hot shell. After cooling, the ceramic is vibrated and blasted off themetal parts and discarded. The balance of the cleaning operations (cutoff, grind, heat treat, straightening, blast) arestraight forward and quite similar to the other casting processes.

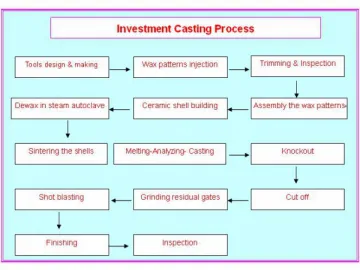

The process is showas the flow-diagram.

美工注意:此处放图片01,下面是图片上的文字:

InvestmentCasting Process Investment Casting Process

Toolsdesign & making Tools design & making

Waxpatterns injection Wax patterns injection

Trimming& Inspection Trimming & Inspection

Assemblythe wax patterns Assembly the wax patterns

Ceramicshell building Ceramic shell building

Dewax in steam autoclave Dewax in steam autoclave

Sinteringthe shells Sinteringthe shells

Melting-Analyzing- Casting Melting-Analyzing- Casting

Knockout Knockout

Cutoff Cut off

Grindingresidual gates Grinding residual gates

Shotblasting Shot blasting

Finishing Finishing

Inspection Inspection

Links:https://www.globefindpro.com/products/86533.html

-

Meat Grinder Casting Parts

Meat Grinder Casting Parts

-

42CrMo Alloy Steel Casting

42CrMo Alloy Steel Casting

-

Stainless Steel Automotive Pipe fittings

Stainless Steel Automotive Pipe fittings

-

Stainless Steel Lock Bolts

Stainless Steel Lock Bolts

-

Stainless Steel Casting Valve Disc Plate

Stainless Steel Casting Valve Disc Plate

-

S20C Mild Steel Casting

S20C Mild Steel Casting

-

Casting Bearing Block

Casting Bearing Block

-

316L Stainless Steel Castings

316L Stainless Steel Castings

-

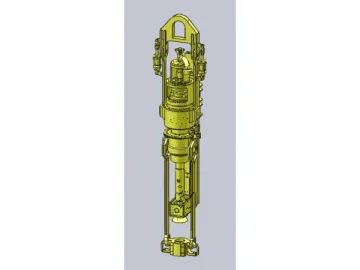

750T Variable Frequency Top Drive Drilling System

750T Variable Frequency Top Drive Drilling System

-

Automotive Air Conditioning Trainer

Automotive Air Conditioning Trainer

-

250T Hydraulic Top Drive Drilling System

250T Hydraulic Top Drive Drilling System

-

Mechanical Assembly and Debugging Training Device

Mechanical Assembly and Debugging Training Device