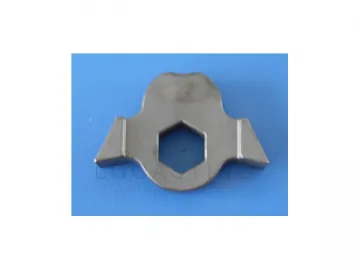

310 Heat Resistant Steel Castings

310 Heat ResistantSteel Castings

美工注意:内页中显示该产品的其他名称

310 Heat Resistant Steel InvestmentCastings

Heat Resistant Steel Casting Gas RangeParts

Steel Casting Boiler Parts

Casting Standards

AISI 310, EN10295 1.4848, JIS G 5122 SCH22

Chemical Composition

| Equivalent Grade | C | Si | Mn | P | S | Cr | Ni |

|

| CK-20 | 0.2 max | 2.0 max | 2.0 max | 0.04 max | 0.04 max | 23.0-27.0 | 19.0-22.0 |

|

| SCH21 | 0.25-0.35 | 1.75 max | 1.5 max | 0.04 max | 0.04 max | 23.0-27.0 | 19.0-22.0 |

|

| SCH22 | 0.35-0.45 | 1.75 max | 1.5 max | 0.04 max | 0.04 max | 23.0-27.0 | 19.0-22.0 |

|

| GX40CrNiSi25-20 | 0.3-0.5 | 1.0-2.5 | 2.0 max | 0.04 max | 0.03 max | 24.0-27.0 | 19.0-22.0 |

|

310 heat resistant steel contains the Cr and Ni elements inside. It shows thegood anti oxidation and corrosion properties. It applies to manufacturing the heat resistant castings,such as the gas stove, boiler, and industrial combustion equipment.

Our company provides the 310 heat resistant casting offour different levels. They all have a big amount of Cr and Ni elements inside.The Cr element therein is the key to enhancing the oxidation and corrosionresistance, and the Ni element helps to form the stable austenitestructure. The 310 heat resistant steelworks well under the high temperature of 1000℃. When the working temperature islower than 1150℃,it has better oxidation resistance and higher thermal strength than the 309heat resistant steel. It is suitable to be used onto the exhaust pipe, thermalexchanger and many other high temperature devices.

Related Names

Corrosion Resistant Casting | Oxidation Resistant Casting

Links:https://www.globefindpro.com/products/86559.html

-

SCM415 Alloy Steel Casting

SCM415 Alloy Steel Casting

-

Boat Fishing Rod Holder

Boat Fishing Rod Holder

-

304L Stainless Steel Castings

304L Stainless Steel Castings

-

Marine Hardware

Marine Hardware

-

Casting Stirring Rod of Food Blender

Casting Stirring Rod of Food Blender

-

Hoisting Machinery Parts

Hoisting Machinery Parts

-

310S Heat Resistant Steel Castings

310S Heat Resistant Steel Castings

-

Stainless Steel Coffee Maker Parts

Stainless Steel Coffee Maker Parts

-

Casting Lock Body

Casting Lock Body

-

430 Stainless Steel Castings

430 Stainless Steel Castings

-

Lock Follower Casting Parts

Lock Follower Casting Parts

-

8620 Alloy Steel Casting

8620 Alloy Steel Casting