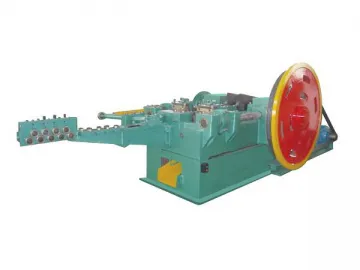

Steel Nail Making Machine

Steel Nail Making Machine

Small and compact in appearance, our scientifically designed steel nail making machine is automatic equipment which can be utilized even in the factory of 25 square meters. So for this reason, it is particularly suitable for small and medium sized enterprises or entrepreneurs. This equipment also holds the advantages of high efficiency and good continuity. It can make the steel nail by one time.

Features

1. This type machine adopts plunger structure and oil lubrication so as to ensure the features such as high speed, low noise generation and less impact.

2. Moreover, our machine can manufacture nails of many varieties and specifications.

Production process

First, the wire will automatically feeding into the working center. Then the nail head will punched by punch pin, at the same time the wire loosed by the nail mould and continually move to the cutting center, in which the wire will be cut by the nail knife with set length. Finally, the finished nails will be automatically ejected by the ejector.

In the nail making process, the auxiliary machines required are wire reel, nail cutter grinder, and nail polishing machine. Nail mold, nail knife, and punch pin are the main wearing parts.

Parameters

Model | Z94-1.6A | Z94-2.8A | Z94-3A | Z94-4A | Z94-6A |

Max. Diameter of Nail (mm) | 1.6 | 2.8 | 3.4 | 4.5 | 6.5 |

Min. Diameter of Nail (mm) | 0.9 | 1.2 | 1.8 | 2.8 | 4.1 |

Max. Length of Nail (mm) | 25 | 50 | 70 | 100 | 200 |

Min. Length of Nail (mm) | 9 | 16 | 30 | 50 | 100 |

Designed Output (pcs/min) | 480-520 | 350 | 320 | 260 | 200 |

Motor Power (kw) | 0.8 | 2.2 | 3 | 4 | 11 |

Speed (rotate/min) | 1380 | 1430 | 1430 | 1430 | 960 |

Weight(approx) (kg) | 375 | 1000 | 1150 | 1978 | 5000 |

Overall Dimensions (mm) | 1000x750x1000 | 1550X1000X1065 | 1970X1200X1200 | 2436X1512X1205 | 3220X1838X1545 |

Wire Reel

It is applied for the wire coil laying.

:()

Nail Cutter Grinder

It is used for grinding the nail knife by the grinding wheel.

:()

Nail Polishing Machine

This machine is used for polishing the nails, caps, etc. After put into the roller, the finished nail will be free from sharp edges and greasy dirt after having been rolled together with the sawdust for about 1 hour. Then, use the sieve plate to separate the sawdust and nails. The nail could become brighter and anti-rust after polishing.

Parameters

Type | SD-400 | SD-600 | SD-1000 | SD-2000 |

Capacity | 400kg | 600kg | 1000kg | 2000kg |

Power of Motor | 3kw | 4kw | 7.5kw | 11kw |

Overall Size | 1640x90x1000 | 1960*1070*1400 | 2000x1500x1400 | 2500x1500x1600 |

:()

Related Names

Round Nail Making Device | Steel Nail Machinery | Snag Machining Device | Nail Processing Equipment

Links:https://www.globefindpro.com/products/86660.html