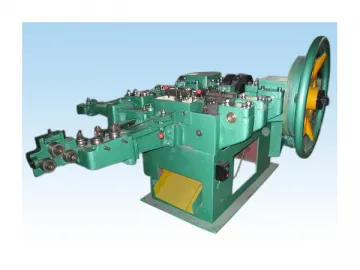

Automatic Nail Making Machine

Automatic Nail Making Machine

Apart from the general steel nails, our newly developed high speed automatic nail making machine with low noise generation also can manufacture special shaped nails such as linoleum nails, roofing nails, double cap nails, U-shaped nails, twist nails, concrete nails, etc. This equipment consists of lubricating system and driving system. The driving system covers wire feeding, wire clamping, cutting, and stamping.

In the nail making process, our equipment has the auxiliary machines like wire reel, nail cutter grinder, and nail polishing machine. The main wearing parts are nail mold, nail knife, and punch pin.

Production Principle

This equipment covers one main crank and two side shafts. Due to the special bearing design, it is smoother in operation as compared to the traditional nail making machine. The main axle is directly driven by the motor. In addition, the two side shafts separately used to control the nail cutter part and nail mold part are pulled via four bevel gear.

Production Process

The wire on the wire wheel will be fed to the working center through the wire roller of the nail making machine, and then the nail head is formed via the stamping of the punch pin after the nail mold clamps the wire tightly. After loosened by the nail mold, the wire will be driven to cutting center through the side shaft. Later, the nail will be cut into the set length. Finally, the finished nails will be automatically eject through the ejector.

Parameters

Model | Z94-6.5C | Z94-5.5C | Z94-4C | Z94-3C | Z94-2C | Z94-1C |

Max. Diameter of Nail (mm) | 6.5 | 5.5 | 4.5 | 3.4 | 2.8 | 1.6 |

Min. Diameter of Nail (mm) | 4.5 | 3.7 | 2.8 | 1.8 | 1.2 | 0.9 |

Max. Length of Nail (mm) | 200 | 150 | 100 | 80 | 50 | 25 |

Min. Length of Nail (mm) | 100 | 80 | 50 | 30 | 16 | 9 |

Designed Output (pcs / min) | 160 | 200 | 260 | 320 | 350 | 450 |

Motor Power (Kw) | 11 | 5.5 | 4 | 3 | 2.2 | 1.5 |

Weight (Approx) (Kg) | 5000 | 2500 | 2000 | 1400 | 1200 | 560 |

Overall Dimensions (mm) | 3200x2200x2200 | 2800x1800x1800 | 2200x1600x1650 | 2000x1400x1400 | 1700x1300x1400 | 1500x1300x1200 |

Wire Reel

It is used for the wire coil laying

:()

Nail Cutter Grinder

It is used for grinding the nail knife by the grinding wheel.

:()

Nail Polishing Machine

This machine is used for polishing the nails, caps, etc. After put into the roller, the finished nail will be free from sharp edges and greasy dirt after having been rolled together with the sawdust for about 1 hour. Then, use the sieve plate to separate the sawdust and nails. The nail could become brighter and anti-rust after polishing.

Parameters

Type | SD-400 | SD-600 | SD-1000 | SD-2000 |

Capacity | 400kg | 600kg | 1000kg | 2000kg |

Power of Motor | 3kw | 4kw | 7.5kw | 11kw |

Overall Size | 1640x90x1000 | 1960*1070*1400 | 2000x1500x1400 | 2500x1500x1600 |

:()

Maintenance

1) Ensure the cleanness of the automatic nail making machine, and the nail mold should be frequently washed. Do not use the rusty wire for nail making.

2) Be sure the well lubrication of the nail making machine before starting. Especially for the new nail making machine, frequently lubricate the machine parts with oil, grease.

3) Regularly use the nail cutter grinder to grind the nail knife.

4) When operating the machine, you should always pay attention to the unusual noise as well as the temperature changes of the frictional parts.

Related Names

Steel Nail Machine | Iron Nail Maker | Equipment for Producing Nail | Rebar Recycling Equipment

Links:https://www.globefindpro.com/products/86681.html

-

Z94-3A Automatic Wire Nail Making Machine

Z94-3A Automatic Wire Nail Making Machine

-

LED Panel

LED Panel

-

Z94-2.8A Automatic Wire Nail Making Machine

Z94-2.8A Automatic Wire Nail Making Machine

-

Z94-3C Automatic Nail Making Machine

Z94-3C Automatic Nail Making Machine

-

Lighting LED Bulb

Lighting LED Bulb

-

Z94-1C Automatic Nail Making Machine

Z94-1C Automatic Nail Making Machine

-

Double Cap Nail Making Machine

Double Cap Nail Making Machine

-

Z94-5.5C Automatic Nail Making Machine

Z94-5.5C Automatic Nail Making Machine

-

5W/6W LED Wall Lamp

5W/6W LED Wall Lamp

-

Z94-4A Automatic Steel Nail Making Machine

Z94-4A Automatic Steel Nail Making Machine

-

Flower Shape Energy Saving Bulb

Flower Shape Energy Saving Bulb

-

LED Track Light

LED Track Light