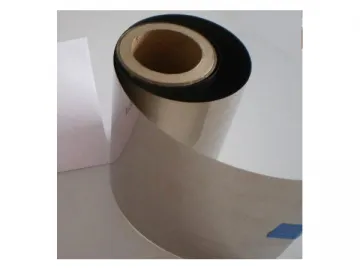

Copper Clad Aluminum Busbar, CCA Busbar

Copper Clad Aluminum Busbar, CCA Busbar

Based on the leading cladding welding manufacturing technology, the copper clad aluminum busbar is made by sheathing the aluminum strip with high quality copper pipe and forming firm metallurgical bonding among the atoms between the copper layer and aluminum strip. The two totally different materials are bonded into an indivisible whole. The product is given the unique composite performance involving the conductivity of copper and the small density of aluminum. The tin plated product also has the weldability and sulfuration resistance that the tin has.

Technical Specification

| Item | Specification (mm) | Carrying Capacity (A) | Weight | |

| Width | Thickness | Alternating Current (35°C) | kg/m | |

| 1 | 25 | 3 | 255 | 0.268 |

| 2 | 30 | 3 | 310 | 0.324 |

| 3 | 30 | 4 | 340 | 0.429 |

| 4 | 40 | 4 | 450 | 0.576 |

| 5 | 40 | 5 | 470 | 0.716 |

| 6 | 45 | 5 | 550 | 0.808 |

| 7 | 50 | 5 | 610 | 0.900 |

| 8 | 50 | 6 | 655 | 1.075 |

| 9 | 60 | 6 | 785 | 1.296 |

| 10 | 80 | 6 | 1045 | 1.738 |

| 11 | 100 | 6 | 1305 | 2.179 |

| 12 | 60 | 8 | 890 | 1.715 |

| 13 | 80 | 8 | 1190 | 2.304 |

| 14 | 100 | 8 | 1485 | 2.893 |

| 15 | 120 | 8 | 1790 | 3.482 |

| 16 | 60 | 10 | 1000 | 2.128 |

| 17 | 80 | 10 | 1330 | 2.864 |

| 18 | 100 | 10 | 1665 | 3.600 |

| 19 | 120 | 10 | 2000 | 4.336 |

| 20 | 150 | 12 | 3000 | 6.504 |

| 21 | 200 | 14 | 4666 | 10.115 |

| Remark: The length of the product can be optional with 1 to 6m/pc. | ||||

Our copper clad aluminum busbar with superior quality is the perfect welding combination of copper and aluminum. Compared with the copper strip, the product has lower density which is merely 38% of that of copper strip, and far higher conductivity than pure aluminum. Meanwhile, by keeping the flexibility of the copper and aluminum, it can be cut, bent and perforated again easily. The product won’t deform easily though suffering high temperature or high pressure.

The copper clad aluminum busbar with appropriate specification can be a substitute for pure copper strip completely. On the basis of keeping excellent conductivity performance just like the copper strip, it comes with the weight decreased by nearly 50%. Hence, the total cost of the product is almost half that of the copper strip. As the optimum alternative to the expensive copper strip, the product is widely applied for producing various distribution boxes, converting stations and other conducting equipment.

Send Message

Links:https://www.globefindpro.com/products/86759.html

-

AL-GPE 40-60 Sports Field Artificial Turf

AL-GPE 40-60 Sports Field Artificial Turf

-

Leisure-Roof Artificial Lawn

Leisure-Roof Artificial Lawn

-

Stainless Steel Coil

Stainless Steel Coil

-

Golf Artificial Turf

Golf Artificial Turf

-

Constantan Tape

Constantan Tape

-

Alloy Wire

Alloy Wire

-

AL-JDS 40-60 Sports Ground Artificial Turf

AL-JDS 40-60 Sports Ground Artificial Turf

-

Nickel Tape

Nickel Tape

-

Leisure Places Artificial Lawn

Leisure Places Artificial Lawn

-

Molybdenum Tape

Molybdenum Tape

-

T5 / T8 Energy Saving Fluorescent Tube

T5 / T8 Energy Saving Fluorescent Tube

-

Electric Heating Strip

Electric Heating Strip