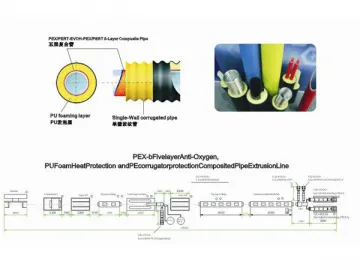

Plastic Composite Pipe Extrusion Line (PEX-B Five Anti-Oxygen Layer, PU Foam Heat Protection, PE Corrugated Protection Layer)

Plastic Composite Pipe Extrusion Line (PEX-B Five Anti-Oxygen Layer, PU Foam Heat Protection, PE Corrugated Protection Layer)

Five layer composite pipe

PU foaming layer

Single wall corrugated pipe

PEX-b five layer anti-oxygen

PU foam heat protection and PE corrugated protection composite pipe extrusion line

Plastic composite pipe extrusion line is mainly composed of extruder, five layer coextrusion die, vacuum sizing, cooling, hauling, cutting, reeling, etc. Thanks to the multi layer coextrusion technology, it can extrude the PEX and PE-RT anti oxygen pipe with the diameter range from 16 to 160mm. Also, it adopts the extrusion die and the dedicated screw for the oxygen resistant material EVOH. The highest production speed can reach over 20m/min. By exchanging different dies, we can produce the oxygen barrier pipe with distinct specifications. In addition, the five layer pipe is covered with PU foam layer and PE corrugated pipe layer. The winding machine can be coiled into disk, which is not only convenient for installation and long distance transportation of hot water, but also helps cut down the heat loss.

Main Specifications

Model | Pipe Extruder | Speed (m/min) | Max. Output (kg/h) | Total Power (kW) | Dimension L×W×H |

FPPCG-40/75-160/200 | FSJ-65X30 (2sets) | 0.4-4 | 220 | 370 | 55×7×3.6 |

FSJ-40X30 (2sets) |

Related Names

Composite Corrugated Pipe Production Line | Extrusion Line for Plastic Composite Pipe | Multiple-Unit Tube Making Machinery

Links:https://www.globefindpro.com/products/87167.html

-

PVC Spiral Reinforced Flexible Hose Extrusion Line

PVC Spiral Reinforced Flexible Hose Extrusion Line

-

UV2030C UV Curable Flatbed Printer

UV2030C UV Curable Flatbed Printer

-

UV1325C UV Curable Flatbed Printer

UV1325C UV Curable Flatbed Printer

-

Odorless Ink

Odorless Ink

-

Cleaning Solution

Cleaning Solution

-

Liquid Lamination Coating

Liquid Lamination Coating

-

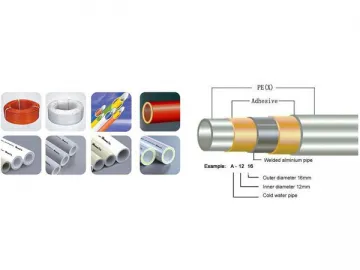

PEX/AL/PEX Composite Pipe High Speed Extrusion Machine

PEX/AL/PEX Composite Pipe High Speed Extrusion Machine

-

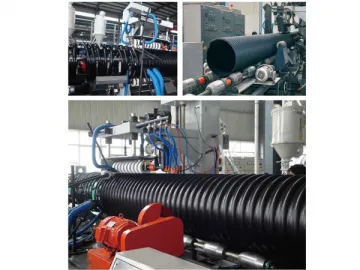

Steel Reinforced PE Spiral Corrugated Pipe Making Machine

Steel Reinforced PE Spiral Corrugated Pipe Making Machine

-

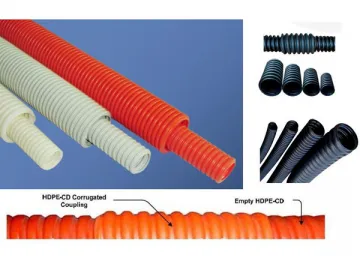

PE/PP/PVC Single Corrugated Pipe Manufacturing Equipment

PE/PP/PVC Single Corrugated Pipe Manufacturing Equipment

-

PE Waterproof Sheet / Geomembrane Fabrication Machine

PE Waterproof Sheet / Geomembrane Fabrication Machine

-

PE Drip Irrigation Tape Making Machine

PE Drip Irrigation Tape Making Machine

-

PP Super Mute Drainage Pipe Production Line

PP Super Mute Drainage Pipe Production Line