Cylindrical Screen Printer

Cylindrical Screen Printer

The cylindrical screen printer is produced specially for printing regular cylindrical and conical articles like cups, bottles, etc. It is suitable for every material and can print every color.

Item Number | HS260R | Printing Speed | 1100pcs/ hour |

Max. Printing Diameter | 80mm | Max. Screen Frame Size | 250×400 mm |

Max. Printing Height of Products | 80mm | Stroke of Screen Frame Moving Up and Down | 160mm |

Air Consumption | 2L/cycle | Power | 1.5kW |

Air Expend/ Cycling | 2.1L | Voltage | 220V/ 1 Phase or 380/ 3 Phase |

Dimension | 1050×1300×1620mm | Net Weight | 120kg |

Technical Parameters of HS350R

Item Number | HS350R | Printing Speed | 1000pcs/ hour |

Max. Printing Size | Diameter: 110mm | Max Screen Frame Size | 350×500 mm |

Air Consumption | 2.1L/ cycle | Power | 20W |

Air Supply | 6 bar | Voltage | 220V/ 1 Phase 50/60HZ |

Dimension | 720×760×1680mm | Net Weight | 170kg |

Technical Parameters of HS500R

Item Number | HS500R | Printing Speed | 800pcs/ hour |

Max. Printing Size | Diameter: 160mm | Max. Screen Frame Size | 400x600 mm |

Air Consumption | 2.1L/cycle | Power | 20W |

Air Supply | 6 bar | Voltage | 220V/ 1 Phase |

Dimension | 800×1150×1750mm | Net Weight | 285kg |

Features

1. The product has two programs involving single cycle printing and automatic printing. It can remember the set program and set printing once, twice, etc.

2. Japanese or German pneumatic components are adopted.

3. The squeegee moves from left to right with German FESTO or ORIGA by using guide pillar structure.

4. The machine is controlled by microcomputer. Each position can be inductive through electric eye.

5. By using guide pillar, the screen frame of the cylindrical screen printer moves up and down with high accuracy and stability.

Links:https://www.globefindpro.com/products/87238.html

-

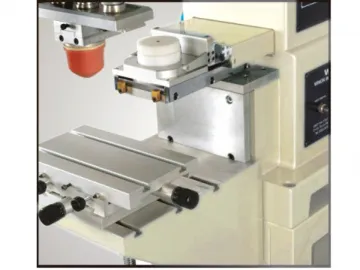

Manual Seal Ink Cup Pad Printing Machine

Manual Seal Ink Cup Pad Printing Machine

-

Automatic Industrial Screen Printing Machine

Automatic Industrial Screen Printing Machine

-

1-Color Turntable Pad Printer

1-Color Turntable Pad Printer

-

Automatic Precision Vacuum Screen Printing Machine

Automatic Precision Vacuum Screen Printing Machine

-

Pad Printing Samples

Pad Printing Samples

-

Automatic Big One Color Pad Printing Machine

Automatic Big One Color Pad Printing Machine

-

Electric Ink Blender/Mixer

Electric Ink Blender/Mixer

-

Automatic Round Screen Printing Machine

Automatic Round Screen Printing Machine

-

One Color Desktop Pad Printer

One Color Desktop Pad Printer

-

Sealed Ink Cup

Sealed Ink Cup

-

Automatic Silk Screen Printing Machine

Automatic Silk Screen Printing Machine

-

Jewelry Box

Jewelry Box