PP Blown Film Line

PP Blown Film Line

We offer three models of PP blown film line. Theirfeatures are described below.

Features

1. This blownfilm line adopts a bottom-blow technique to produce polypropylene plastic film.The obtained film has good transparency without folds, corrugations, flowliners, or other imperfections.

2. The screw and barrel are made of 38CrMoAl alloy steel and processed withnitrogen treatment for the highest level of rigidity and corrosion resistance.

3. The mould head is plated with hard chromium and designed with a screwmandrel structure with uniformly smooth material discharging capabilities.

4. The incorporated air-cooling apparatus is engineered with a labyrinth typestructure and features functions such as uniform air-jut quantity, automaticheating, and automatic temperature regulation.

5. The coiling device utilizes a torque motor to maintain proper tension,enabling easy roll collection and convenient roll replacement.

6. Our PP blown film line comes with an air compressor and three water ringswith different sizes.

Optional Equipment

1. Auto loader

2. Rotary die device

3. Film surface treater

4. Double-station winder

Main Technical Variables

| Model | XY-55 | XY-60 | XY-70 |

| Diameter of screw | φ55 | φ60 | φ70 |

| Reduced diameter of film (mm) | 100-500 | 100-600 | 300-800 |

| Single-face Thickness of film (mm) | 0.01-0.1 | ||

| Max. Output (kg/h) | 30 | 45 | 60 |

| L/D Ratio | 28 : 1 | ||

| Power of main motor (kW) | 11 | 15 | 18.5 |

| Power of Traction motor (kW) | 1.1 | 1.1 | 1.5 |

| Length of Traction roller (mm) | 550 | 650 | 850 |

| Dimensions (L×W×H) (mm) | 4500×2000×3500 | 4800×2500×3800 | 5000×2800×4000 |

| Weight (T) | 3 | 4 | 5 |

Related Names

Polypropylene Film Extrusion Machine | Blown Film Extrusion Line | PP BlownFilm Plant

Links:https://www.globefindpro.com/products/87355.html

-

Non Woven Bag Printing Machine

Non Woven Bag Printing Machine

-

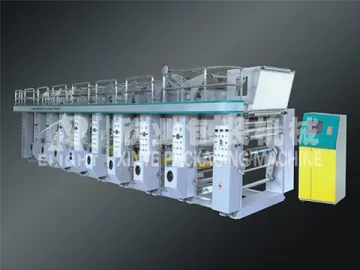

XYASY-E800/1000 6-Color Rotogravure Printer

XYASY-E800/1000 6-Color Rotogravure Printer

-

Arc-Shaped Plastic Bag Making Machine

Arc-Shaped Plastic Bag Making Machine

-

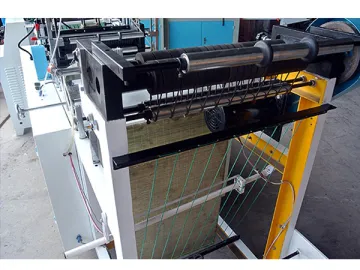

XYASY-E8-1100 Gravure Printer

XYASY-E8-1100 Gravure Printer

-

Foldable Sit-Up Bench

Foldable Sit-Up Bench

-

High Strength Reduction Gearbox

High Strength Reduction Gearbox

-

Rotating Die Head Blown Film Line

Rotating Die Head Blown Film Line

-

Painted Barbell Cast Iron Disc Weight Plate

Painted Barbell Cast Iron Disc Weight Plate

-

Double Color Plastic Bag Making Machine

Double Color Plastic Bag Making Machine

-

Plastic Vest Carrier Bag Making Machine

Plastic Vest Carrier Bag Making Machine

-

Multifunction Thermal Cutting Plastic Bag Making Machine

Multifunction Thermal Cutting Plastic Bag Making Machine

-

PE Coated Barbell Cement and Iron Sand Weight Plate

PE Coated Barbell Cement and Iron Sand Weight Plate