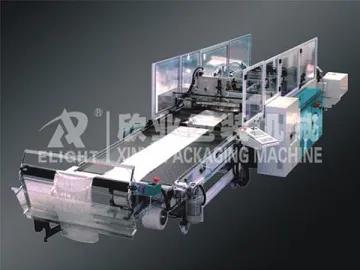

Two Layer Co-extrusion Blown Film Line

TwoLayer Co-extrusion Blown Film Line

The two layer co-extrusion blown film line is used to produce HDPE, LDPE, andLLDPE films.

Features

1. Dual layer co-extrusion laminated filmcan extend the potential shelf life of liquid products.

2. The cylinder and screw rod of the extruder are manufactured with premiumalloy steel. A high degree of hardness and durability is achieved after postprocessing of nitrogen treatment and precision finishing.

3. The auxiliary machineof our two layer co-extrusion blown film line is equipped with bubblestabilizing rings and it has a working platform that enables easy operation.

4. The dual winding and rewinding units are coupled with a torque motor and arecapable of maintaining the tension needed for easy roll swapping and rollcollection.

Technical Specifications

| Model | SJ-45×2/FM1000 | SJ-50×2/FM1200 | SJ-55×2/FM1500 |

| Screw Diameter | 2×45mm | 2×50mm | 2×55mm |

| Screw Ratio | L/D30:1 | ||

| Screw Speed | 12-120r/min | ||

| Output | 35kg/h | 50kg/h | 60kg/h |

| Power of Main Motor | 2×11KW | 2×15KW | 2×15KW |

| Caliber of Film Head | 200-250mm | 250-300mm | 300-350mm |

| Rotational Mode of Machine Head | constantly revolve | constantly revolve | constantly revolve |

| Single-sided Thickness of Film | 0.02-0.10mm | ||

| Max. Folding Width of Film | 1000mm | 1200mm | 1500mm |

| Electric Total Capacity | 42Kw | 53Kw | 65Kw |

| Weight of Machine | 3500kg | 4500kg | 1500kg |

| Overall Dimensions | 4200×2200×4600mm | 4600×2400×5000mm | 5200×2700×6000mm |

Related Names

Two Layer Co-extruding Film Blowing Machine | Blown Film Machine | ExtrusionBlow Molding Machine

Links:https://www.globefindpro.com/products/87363.html

-

Double Color Blown Film Line

Double Color Blown Film Line

-

Double Head Blown Film Line

Double Head Blown Film Line

-

2-Color Flexographic Printer

2-Color Flexographic Printer

-

T-shirt Bag Handle Cutting Machine

T-shirt Bag Handle Cutting Machine

-

Double Arc Shaped Plastic Bag Making Machine

Double Arc Shaped Plastic Bag Making Machine

-

Plastic Recycling Machine

Plastic Recycling Machine

-

Semi-Automatic Patch Bag Making Machine

Semi-Automatic Patch Bag Making Machine

-

High Strength Reduction Gearbox

High Strength Reduction Gearbox

-

Foldable Sit-Up Bench

Foldable Sit-Up Bench

-

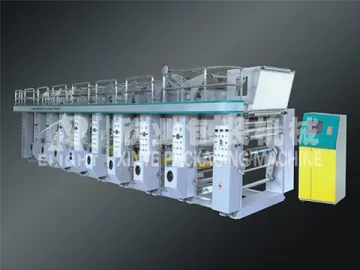

XYASY-E8-1100 Gravure Printer

XYASY-E8-1100 Gravure Printer

-

Arc-Shaped Plastic Bag Making Machine

Arc-Shaped Plastic Bag Making Machine

-

XYASY-E800/1000 6-Color Rotogravure Printer

XYASY-E800/1000 6-Color Rotogravure Printer