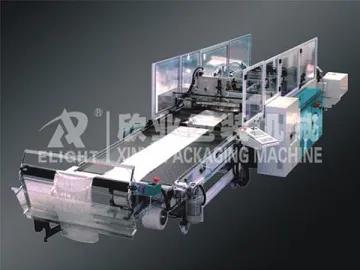

Three Layer Co-extrusion Blown Film Line

Three Layer Co-extrusion Blown Film Line

The three layer co-extrusion blown film line adopts a rotary head and iscapable of processing films of the type LDPE, HDPE, LLDPE, and MLLPE.

Features

1. The CE certified blown film unit is equipped with a spiralmandrel die head that enables continuous operations with 360 degrees of rotaryfreedom.

2. The convenient screen pack changer is scientifically designed to allow forsafe and reliable operations.

3. The three layer co-extrusion blown film line can be augmented with anassortment of functional parts, such as the length counting device, verticalcutting device, cooling water row pipe, film spreading roller, and the scrapcollecting device.

Technical Specifications

| Model | SJ-45×3/FM1000 | SJ-50×3/FM1200 | SJ-55×3/FM1500 |

| Screw Diameter | 45mm | 55mm | 55mm |

| Screw Ratio | L/D30:1 | ||

| Screw Speed | 15-150r/min | ||

| Power of Main Motor | 11KW×3 | 15KW×3 | 18.5KW×3 |

| Range of Die | ¢130¢180 | ¢130¢250 | ¢130¢300 |

| Thickness of Film | 0.01-0.10mm | ||

| Max. Folding Width of Film | 1000mm | 1200mm | 1500mm |

| Electric Total Capacity | 76KW | 88KW | 102KW |

| Weight of Machine | 4200kg | 5300kg | 6200kg |

| Overall Dimensions | 6600×4100×5000mm | 6800×4300×6000mm | 7000×4800×6800mm |

The three layer co-extrusion blown film line isdeveloped by our company based on current market trends. Its design is optimizedwith the defining elements of analogous machines from both domestic and foreignmanufacturers.

Our three layerco-extrusion blown film machine isequipped with a horizontal extruder for continuous blowing action. It produces packaging films witha thickness of 0.08mm and afold width of 1200, 1300, or 1500mm.The resulting films have good insulation and exhibit excellent resistanceagainst elements such as oil, wind, rain, and humidity.

Extremely versatile, the plasticsheet making equipment can be utilized for both light and heavy-dutypackaging.

Links:https://www.globefindpro.com/products/87373.html

-

Nonwoven Zipper Bag Making Machine

Nonwoven Zipper Bag Making Machine

-

Water Cooled Plastic Granulator

Water Cooled Plastic Granulator

-

Automatic Soft Loop Handle Bag Making Machine

Automatic Soft Loop Handle Bag Making Machine

-

Plastic T-Shirt Bag Making Machine

Plastic T-Shirt Bag Making Machine

-

6-Colour Flexographic Printer

6-Colour Flexographic Printer

-

Flexo Plate Making Machine

Flexo Plate Making Machine

-

Fully Automatic Non Woven Bag Making Machine

Fully Automatic Non Woven Bag Making Machine

-

Plastic Shredder

Plastic Shredder

-

Plastic Recycling Machine

Plastic Recycling Machine

-

Double Arc Shaped Plastic Bag Making Machine

Double Arc Shaped Plastic Bag Making Machine

-

T-shirt Bag Handle Cutting Machine

T-shirt Bag Handle Cutting Machine

-

2-Color Flexographic Printer

2-Color Flexographic Printer