Plastic Mixer

Plastic Mixer

The plastic mixerincorporates Japanese design principles. It efficiently recycles used and left over plastics forreproduction purposes by making use of concepts like frictional heating,continuous stirring, multi-tool quick grinding, and flash freeze inducedcontraction.

Functions

1. Our plastic mixer recycles waste and leftover materials ofvarious soft plastic films, bags, filaments, ribbons, sheets, and tubes. Thesematerials are made from polyvinyl chloride, high density polyethylene, orlinear low density polyethylene.

2. Degradable plastic films and angle materials are grinded and granulated.

3. Chemical fiber waste materials can also be processed for reproduction.

4. This plasticgranulator is highly versatile and can act as a substitute for eitherthe drying or blending machine.

Technical Specifications

| Capacity of Barrel | 100L | 150L |

| Output Capacity | 30-60kg/h | 60-80kg/h |

| Main Motor Power | 15kW | 18kW |

| Water Adding Device | 125W | |

| Heating Power | 1.5kW | |

| Rotary Speed of Main Shaft | 660r/min | |

| Overall Dimensions | 1300×600×1300 mm | 1500×700×1400mm |

Features

1. The three-in-one process isdesigned for triple-action milling, mixing, and staining.

2. Granulating at lower temperaturedoes not hinder performance or damage the molecular structure of processedmaterials.

3. The gap between blades is adjustable and it is convenient to replace theblades.

4. Workingefficiency is high and power consumption is low. Asingle ton of daily production can be achieved with only 200 kWh.

5. The plasticmixer has a simple structure and is easy to operate.

6. This grinding milloccupies less space and effectively reduces clutter.

Links:https://www.globefindpro.com/products/87382.html

-

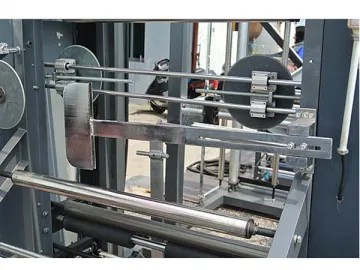

Film Winding Machine

Film Winding Machine

-

High Speed Film Extruder Screen Changer

High Speed Film Extruder Screen Changer

-

Anti-static Box

Anti-static Box

-

Rotary Die Head PP Blown Film Line

Rotary Die Head PP Blown Film Line

-

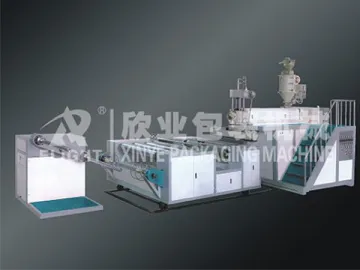

Polyethylene Bubble Film Extrusion Line

Polyethylene Bubble Film Extrusion Line

-

Non Woven Bag Making Machine

Non Woven Bag Making Machine

-

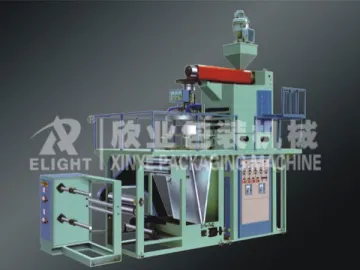

Blown Film Line with Offset Printing

Blown Film Line with Offset Printing

-

Digital Corona Treatment Device

Digital Corona Treatment Device

-

Flexo Plate Making Machine

Flexo Plate Making Machine

-

6-Colour Flexographic Printer

6-Colour Flexographic Printer

-

Plastic T-Shirt Bag Making Machine

Plastic T-Shirt Bag Making Machine

-

Automatic Soft Loop Handle Bag Making Machine

Automatic Soft Loop Handle Bag Making Machine