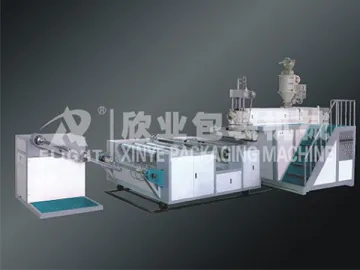

Polyethylene Bubble Film Extrusion Line

PolyethyleneBubble Film Extrusion Line

Our polyethylene bubble filmextrusion line is designed with a single screw and features exceptional outputwith smooth and reliable performance. A single pass shaping techniqueenables high working efficiency and produces outstanding product quality. Thescientifically optimized structural design allows for easy operation andconvenient maintenance.

Both ordinary and composite polyethylene air cushion films are popular packingmediums. Transparent and resilient against corrosion, these cushioningmaterials have excellent shock resistance and heat sealing properties. Thefilms produced by the polyethylene bubble film extrusion line can often befound in the packaging of post parcels, household wares, precise instruments,polyurethane furniture, etc.

| Model | Screw diameter | Film width | Output | Power | L/d |

| XYPE-2000 | Φ75mm and 70mm | 2000mm | 80kg/h | 90kW | 30:1 |

| XYPE-1500 | Φ85mm | 1500mm | 65kg/h | 68kW | |

| XYPE-1200 | Φ75mm | 1200mm | 50kg/h | 58kW | |

| XYPE-1000 | Φ65mm | 1000mm | 40kg/h | 48kW | |

| XYPE-650 | Φ55mm | 650mm | 25kg/h | 30kW |

TechnicalSpecifications of Polyethylene Bubble Film Extrusion Line

1. Extruder: 1pc

Screw Diameter: Ф85 mm

Screw Ratio (L/ D):30:1

Material of Screw Feed Barrel:38CrMoA1A after NitrogenTreatment (Zhoushan,Zhejiang)

Production Place of Drive Motor: Shanghai

Speed Adjustment Mode: Variable Frequency Speed Regulation (Ourui, Yantai,Shandong)

Power of Drive Motor: 22KW

Heating Method: Cast Aluminum Heater

Heating Power: 13KW

Heating Sector: 4 Sectors

Production Place of Digital Temperature Controller: Yuyao, Zhejiang

2. Machine Head: 1 set

Quantity of Extruded Sheet: Two Layers

Machine Head Structure: Coat-hanger Type

Product Width: 1500mm

Heating Method: Cast Aluminum Heater

Heating Sector: 5 Sectors

Changing Method: Automatic Screen Changer

3. Moulding Unit: Two Strip

Width: 1600mm

Moulding Type: VacuumForming (Negative Pressure )

Cooling Type: Water Cooling

Production Place of Drive Motor: Shanghai

Speed Adjustment Mode: Variable Frequency Speed Regulation (Ourui, Yantai,Shandong)

Power of Drive Motor: 3.0KW

Diameter of Bubble Roll(2pcs): Ф10, Ф6

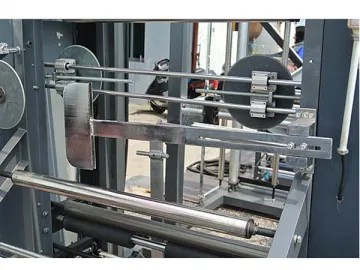

4. Traction System

Diameter of Flattening Roll: 260mm

Material of Flattening Roll: Chromium Plated Steel

Quantity of Flattening Roll: 2pcs

Diameter of Slide Roll: 60mm

Quantity of Slide Roll: 2pcs

5. Rolling System: 1 pc

Rolling Way: Automatic Rolling

Station: Double Station

Motor: Torque Motor (Variable Frequency Speed Regulation)

Power: 2.2KW

Related Names

PE Air-Cushion Film Making Equipment | PE Bubble Film Making Machine | AirBubble Film Machinery

Links:https://www.globefindpro.com/products/87388.html

-

Non Woven Bag Making Machine

Non Woven Bag Making Machine

-

Pneumatic Punching Machine

Pneumatic Punching Machine

-

High Speed Cutting Machine

High Speed Cutting Machine

-

HLG465 250W Induction Industrial High Bay Lighting

HLG465 250W Induction Industrial High Bay Lighting

-

HLG443 120W High Bay Induction Light

HLG443 120W High Bay Induction Light

-

HLG469 40W Induction High Bay

HLG469 40W Induction High Bay

-

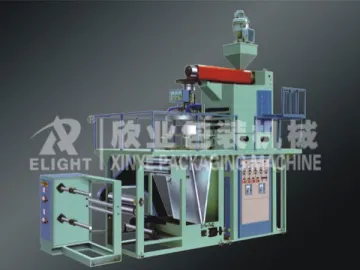

Rotary Die Head PP Blown Film Line

Rotary Die Head PP Blown Film Line

-

Anti-static Box

Anti-static Box

-

High Speed Film Extruder Screen Changer

High Speed Film Extruder Screen Changer

-

Film Winding Machine

Film Winding Machine

-

Plastic Mixer

Plastic Mixer

-

Blown Film Line with Offset Printing

Blown Film Line with Offset Printing