Hi-G Dryer Shaker

Hi-G Dryer Shaker

Hi-G dryer shaker has long shaker deck and large capacity, and it is designed for waste management of drilling cuttings from primary solids control equipment such as shale shaker, desander and desilter. Our product can dry the solids for transportation, and then further treatment for the fluids is able to be executed. Its screen area is 3.2m2, and the screen length on the deck is 2550mm with 3 panel shaker screens. This equipment is able to run at 7.5G, and the G force can be set at different values according to specific working condition. In addition, the vibration mode is linear motion, and BEM is an optional choice. After the drilling mud cutting is processed with our Hi-G dryer shaker, the fluids will be treated by the oilfield decanter centrifuge. In this way, the useful drilling mud is recycled, and the cutting disposal cost is also cut down.

Technical Parameters

Model | GNZS853HG |

Vibration Mode | Linear Motion |

Treating Capacity | 140m3/h (615GPM), API40 |

Motor Power | 2×1.72kW |

Vibration Strength | 7.5G (Adjustable) |

Deck Adjustment | -1°~5° |

Shaker Screen Area | 3.2m2 |

Deck Length | 2550mm |

Weir Height | Buffer box top type:1042mm, back type:944mm |

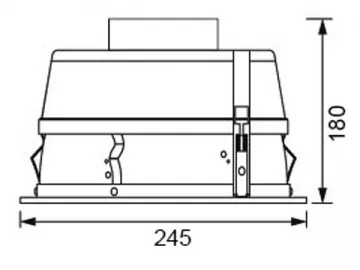

Dimension | 2830×1884×1448mm (top feed)3180×1884×1340mm (back feed) |

Weight | 1650kg |

Remarks | Treating capacity is tested with mud 1.2g/cm3 and viscosity 45s. |

Features

1. Design: ANSYS finite element analysis is applied to optimize the structure of Hi-G dryer shaker.

2. Vibrating Motor: Italy OLI Brand which meets IEC Ex and ATEX standards.

3. Electrical Components: Siemens and Schneider.

4. Deck: Q345 high strength alloy is used to produce the deck, and the entire shaker deck is processed with heat treatment. The mechanical deck is adjustable during operation which guarantees the reliable performance.

5. Steel frame pyramid shaker screen is adopted to maximize effective screen area.

6. The wedged type shaker screen allows convenient and fast screen change.

7. Metal and rubber composite material is applied to manufacture dumping spring, and the long service life is guaranteed.

8. Surface painting and coating adopt heavy anticorrosive Japan Kansai paint.

Links:https://www.globefindpro.com/products/87489.html

-

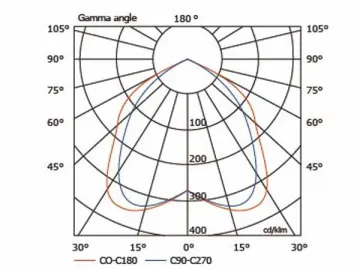

Induction Down Light

Induction Down Light

-

HLG465 150W Induction Industrial Light

HLG465 150W Induction Industrial Light

-

HLG469 150W Induction Industrial Light

HLG469 150W Induction Industrial Light

-

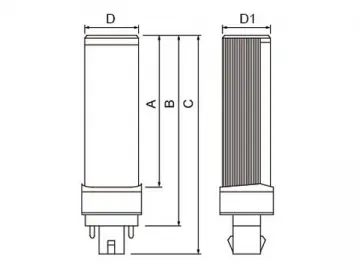

G23 G24 Plug-in LED Lamp

G23 G24 Plug-in LED Lamp

-

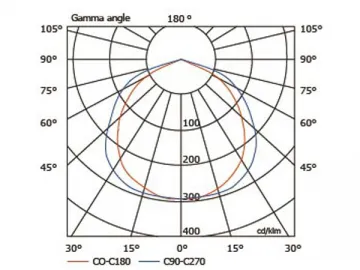

200W Industrial Induction Light

200W Industrial Induction Light

-

HLG469 250W Induction Industrial High Bay Lighting

HLG469 250W Induction Industrial High Bay Lighting

-

80W Ceiling Induction Light

80W Ceiling Induction Light

-

120W High Bay Induction Light

120W High Bay Induction Light

-

40W Induction Ceiling Light

40W Induction Ceiling Light

-

40W Induction High Bay

40W Induction High Bay

-

40W Induction Lamp with Electrical Ballast

40W Induction Lamp with Electrical Ballast

-

150W Industrial Induction Light

150W Industrial Induction Light