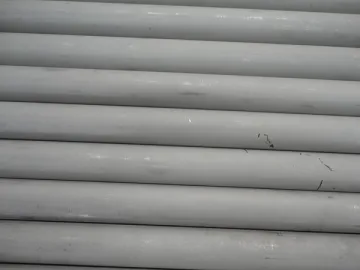

Austenitic Stainless Steel Tube

AusteniticStainless Steel Tube

Containing a highconcentration of chromium and nickel, our non-magnetic austenitic stainlesssteel tube which is usually made of the well-known 300 seriesiron-chromium-nickel steels, features excellent resistance to corrosion andsuperior mechanical behavior. Due to its unusually fine coldworkability, our product can be greatly hardened by cold processing rather thanheat treatment.

Grade

1. Straight grade austenitic stainless steeltube has the carbon content up to 0.08%.

2. L grade type contains no more than 0.03%carbon without carbide precipitation, and features excellent resistance tocorrosion. However, it is more expensive and imparts great physical strength atelevated temperature. Commonly, it is dual certified such as 304/304L, 316/316L, etc.

3. H grade stainless steel pipe possesses the carbon contentranging from 0.04% to 0.10%. Therefore, it can be used at high temperature. Forinstance, it is suitable for the application where annealing after welding isout of commission.

Type

| Type | Features |

| Type 304 | As the most common austenitic stainless steel or grade which contains about 18% chromium and 8% nickel, it is applicable for chemical processing equipment, food and beverage industry, and heat exchanger. |

| Type 316 | Apart from the contents like 16% to 18% chromium and 11% to 14% nickel, Type 316 is also infused with at least 2% molybdenum to prevent pit type attack. Therefore, it is widely applied to chemical processing industry, pulp and paper industry, food and beverage industry, or other corrosive environment. |

| Type 317 | Featuring higher molybdenum content no less than 3% as compared to 316, it is suitable for extremely corrosive environment like stacks containing scrubbers. |

| Type 317L | It has the maximum carbon content of 0.030% and maximum silicon content of 0.75% to offer excellent anti-corrosion performance. |

| Type 317LM | It contains at least 4.00% molybdenum content. |

| Type 317LMN | It comes with molybdenum content no more than 4.00% as well as nitrogen content no more than 0.15%. |

| Type 321 Type 347 | These grades mainly applicable for the aircraft industry feature excellent anti-corrosion property. Type 321 is added with titanium, as well as Type 347 contains the additions like tantalum and columbium. |

Links:https://www.globefindpro.com/products/87682.html

-

Intelligent Car Digital Video Recorder

Intelligent Car Digital Video Recorder

-

ASTM/ANSI/ASME Stainless Steel Seamless Pipe

ASTM/ANSI/ASME Stainless Steel Seamless Pipe

-

Stainless Steel Pipe Fittings

Stainless Steel Pipe Fittings

-

IP Door Access Controller (Four Readers)

IP Door Access Controller (Four Readers)

-

TP347/347H Seamless Stainless Steel Pipe

TP347/347H Seamless Stainless Steel Pipe

-

TP310/310S Stainless Steel Seamless Pipe

TP310/310S Stainless Steel Seamless Pipe

-

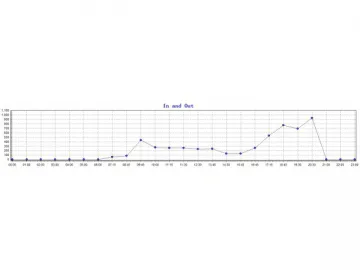

WISECOUNT Web Traffic Analysis System

WISECOUNT Web Traffic Analysis System

-

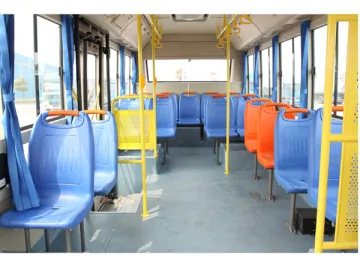

ZGT6739 City Public Bus

ZGT6739 City Public Bus

-

JIS Stainless Steel Tube

JIS Stainless Steel Tube

-

ZGT6600 Light Bus

ZGT6600 Light Bus

-

ZGT6763 Passenger Bus

ZGT6763 Passenger Bus

-

Chemical Composition of Stainless Tube

Chemical Composition of Stainless Tube