Powder Processing Line with Horizontal Classifier

Powder Processing Line withHorizontal Classifier

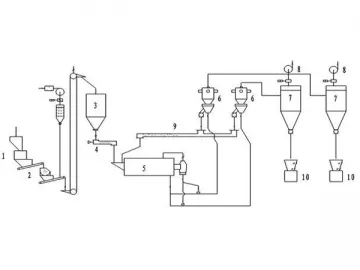

The dust control for powder processing lineis facilitated through the utilization of the draft fan, dust collector,and pneumatic conveying system, in addition to standard configurations such asjaw crusher, hammer crusher, ball mill, horizontal classifier, and more .

High quality filtering materialsguarantee for the emission of dust to be under 40 mg/m³, and 20 mg/m³ by post production. In order to prevent dust leakage and environmental pollution, the powderprocessing equipment completes all proceduresin a negative pressure vacuum.

Ball Mill ofthe Powder Processing Line

1. The powderprocessing line with horizontal classifier is especially designed toaccommodate ultra fine mineral processing.

2. We have optimized the length to diameterratio of the ball mill.

3. A grid plate is attached to the grindingend piece and allows for the smooth discharge of materials. This prevents the dilation of the tube andeliminates the need for external cooling.

4. The grindingmedium is chosen based on product requirements and is capable of high grindingefficiency.

5. The synergy between the onboard drive andassociated grinding functions allows us to minimize energy consumption to thefullest extent.

6. The ball mill forms a closed system withthe classifier. Material transfer isconducted through negative pressure vacuum and emits no airborne powders.

Horizontal Classifier of the Powder Processing Line

1. The HFW multi-rotor classifier implements preciseprocedural control that provides excellent top-cutting capabilities.

2. Theair flow may be calibrated to improve operation efficiency.

3. Theoptimized rotor design significantly improves energy efficiency.

4. Particledistribution greatly varies depending on the arrangement of classifiers, whichmay be altered to accommodate processing techniques.

Dosing Systems for the Powder Processing Line

1.Material feed for the ball mill is achieved through a precise dosing system. Itoffers stable feeding all the time.

2. Material feed for the horizontal classifier is also achieved via a dosingsystem, and the system is interlocked withthe mill outlet and ensures system stability while regulating particlesize.

3. Thedosing pump can be timed for release.

4. Boththe silo and bucket elevator have level indicators to resume automatic controlof the entire power processing line.

5. PLC (Programmable Logic Controller) is used to indicate operational status, and is very easyto operate.

Pollution Control Facilities

1.In order to satisfy noise and environmental protection regulations, our powder processing line adopts the membrane filtering, resulting in a pollutant powder discharge rate lessthan 20mg/m3.

2. Apowerful silencer is attached, reducing noise levels to below 80dB(A).

3. Liquidsused for water cooling are looped continuously and does not require dischargingor refilling.

Applications

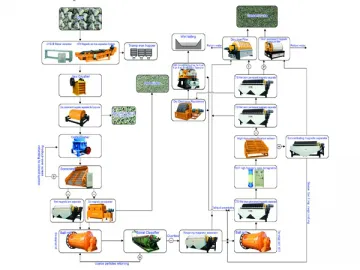

The scope of viable feed for the powder processing line includes soft materials and hard materials. Soft materials include substances such asslag, barite, marble, calcite, gypsum, limestone, etc. Hard materials include substances such asquartz, zircon, feldspar, corundum, carborundum,fine cement, etc.

1.Jaw Crusher 2.Hammer Crusher/Lifting Machine 3. Material StoreChamber 4. Dosing System 5. Ball Mill 6.Horizontal Classifier 7. Dust Catcher 8. Induced Draft Fan 9. Coarse-Particle Return System 10. Packaging

Technical Specifications

| Item | Model | |||||

| HMFW-05 | HMFW-10 | HMFW-20 | HMFW-40 | HMFW-60 | HMFW-80 | |

| Ball mill model | Ф1200X4500 | Ф1500X5700 | Ф1830X7000 | Ф2200X6400 | Ф2400X7000 | Ф2600X7500 |

| Classifier model | HFW315 | HFW3315 | HFW4315 | HFW6315 | 2HFW4315 | 2HFW6315 |

| General power of the whole production line (kW) | ≤100 | ≤330 | ≤510 | ≤715 | ≤930 | ≤1350 |

| Production capacity (kg/h) | 450-600 | 1200-1480 | 2100-2300 | 3100-3600 | 4000-4300 | 5700-6000 |

| Particle size (um) | 3~50 | 3~50 | 3~50 | 3~50 | 3~50 | 3~50 |

| Classifying granularity | D97 | D97 | D97 | D97 | D97 | D97 |

| Filter area (m2) | ≥60 | ≥160 | ≥240 | ≥400 | ≥480 | ≥800 |

| Thickness of dust(mg/m3) | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 | ≤40 |

| Operation | continuous | |||||

Note: All parameters correspond with 1250 mesh GCC and should only be used as aframe of reference. Different materialfrom variable sources will yield a different set of data.

| Powder Processing Line with Horizontal Classifier - Huate | |

| Keywords | Powder processing line, horizontal classifier, ball mill, jaw crusher, hammer crusher, China powder processing equipment supplier |

| Description | While effectively crushing and grinding materials into fine powders, the powder processing line is also outfitted with dust collection and noise reduction facilities to reduce pollution. |

Links:https://www.globefindpro.com/products/87795.html

-

Mud Magnetic Separator

Mud Magnetic Separator

-

Dry Magnetic Separator for Recycling

Dry Magnetic Separator for Recycling

-

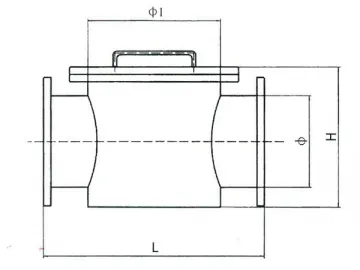

Conduit Self-Cleaning Iron Separator

Conduit Self-Cleaning Iron Separator

-

Vibration Mill

Vibration Mill

-

Oil Forced Circulation Electromagnetic Separator

Oil Forced Circulation Electromagnetic Separator

-

Non-Ferrous Metal Separation Line

Non-Ferrous Metal Separation Line

-

Magnetic Iron Separator

Magnetic Iron Separator

-

Eddy Current Separator

Eddy Current Separator

-

Electromagnetic Stirrer

Electromagnetic Stirrer

-

Conduit Permanent Iron Separator

Conduit Permanent Iron Separator

-

Suspended Permanent Magnetic Separator

Suspended Permanent Magnetic Separator

-

Permanent Magnetic Drum

Permanent Magnetic Drum