Vibration Mill

Vibration Mill

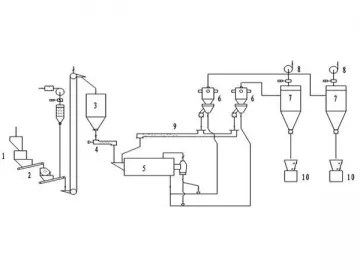

The HMZ series vibration mill harnesses the destructive powergenerated through high frequency vibrations and utilizes it to pulverizematerials within the milling chamber. Abrasive mediums such as spheres, rods, and basswood are used as catalystsand accelerate the process through rubbing, shearing, and paring actions.

Characteristics

1. Our vibration grinding machine features low energyconsumption and high production capacity. With over a thousand crashing, shearing, and rubbing actions per minute,the overall efficiency of the contraption is 10 times that of the ball mill.

2. Highly versatilemilling techniques allows for wide industrial applications. In order to accommodate materialprerequisites, the pulverizer is capable of dryor wet processing. Other techniquesinclude the usage of inert gases, flash freezing, etc.

3. The vibration mill may be operated separately or in combinationwith a classifier to manufacture super fine products.

4. There are many industrial applicationsfor the vibration mill. For instance,within the mining industry, it often acts as an ore crusher to facilitate super fine crushing for various types of ores. The metallurgy industry uses it as a grinder to process raw materials, waste residue, hard alloys, etc.

Technical Parameter

| Model | Volume (L) | Power (kw) | Crushing Size (mesh) | Capacity (kg/h) |

| HMZ10 | 10 | 0.55 | 100~1000 | 1~2 |

| HMZ30 | 30 | 1.1 | 3~15 | |

| HMZ50 | 50 | 2.2 | 5~20 | |

| HMZ100 | 100 | 5.5 | 20~100 | |

| HMZ200 | 200 | 10 | 50~200 |

2HMZ Vibration Mill

Pre-Mill Vertical Mill

The 2HMZ high efficiency vibration mill is a newly introduced model. It is designed for fine crushing as well ascoarse or fine milling. The machine is often utilized to process materials such as iron ore, steel slag, cokewith water, glass raw material, cement clinker material, etc.

Features

1. Compact and highly efficient, this grind mill's energy consumption is only a third that of thetraditional mill.

2. It canaccommodate materials with widths and lengths of up to 40mm. For fine milling, the size of the resulting product may be calibratedbetween 5um and 45um. When used incombination with a classifier, this size can be further refined within a rangeof 800 to 1250mesh.

3. Theresulting shape of the product resembles a multi-edged sphere.

4. Our vibration mill is capable of dry, wet, and vacuum milling.

5. Thevibration spring is created from rubber. It is low noise and ideal for the steady starting or stopping of machineoperation.

Technical Specifications

| Model | Volume (L) | Power (kw) | Feeding Size (mm) | Product Size (mesh) | Capacity (T/h) |

| 2HMZ100 | 100 | 15 | ≤10 | -200 | 0.2~0.3 |

| 2HMZ200 | 200 | 30 | 0.4~0.6 | ||

| 2HMZ400 | 400 | 55 | 0.8~1.2 | ||

| 2HMZ600 | 600 | 75 | 1.0~1.5 | ||

| 2HMZ800 | 800 | 90 | 1.5~2.5 |

Note: The data in the diagram is shown as silicon carbon only as an example.The capacity varies with different materials and product sizes.

| Vibration Mill - Huate | |

| Keywords | Vibration mill, vibration grinding machine, grinder, grind mill, pulverizer, ore crusher, China vertical mill manufacturer |

| Description | Huate 2HMz high efficiency vibration mill is designed for ore crushing as well as other types of particle size reduction purposes. Its overall efficiency is 10 times that of the ball mill. |

Links:https://www.globefindpro.com/products/87799.html

-

Oil Forced Circulation Electromagnetic Separator

Oil Forced Circulation Electromagnetic Separator

-

Non-Ferrous Metal Separation Line

Non-Ferrous Metal Separation Line

-

Self-Cleaning Permanent Magnetic Separator

Self-Cleaning Permanent Magnetic Separator

-

Vacuum Disc Filter

Vacuum Disc Filter

-

Metal Detector

Metal Detector

-

Industrial Energy Efficiency Project

Industrial Energy Efficiency Project

-

Conduit Self-Cleaning Iron Separator

Conduit Self-Cleaning Iron Separator

-

Dry Magnetic Separator for Recycling

Dry Magnetic Separator for Recycling

-

Mud Magnetic Separator

Mud Magnetic Separator

-

Powder Processing Line with Horizontal Classifier

Powder Processing Line with Horizontal Classifier

-

Magnetic Iron Separator

Magnetic Iron Separator

-

Eddy Current Separator

Eddy Current Separator