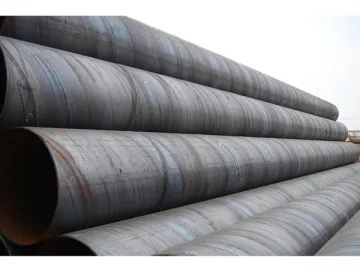

Galvanized Steel Pipe

Galvanized Steel Pipe

Generally, galvanization treatment is applied onordinary steel to improve the corrosion resistance and extend service life. Our company can provide a seriesof galvanized steel pipe with reliable performance. Advanced technique is usedin this product and alloy layer can be formed by reaction of molten metal andiron matrix. So iron matrix and layer can combine together. The detailedprocess is as follows. Firstly, steel tube is pickled to remove iron oxide onthe surface. After that, it is cleaned by aqueous solution of ammonium chlorideor zinc chloride or a combination solution of them. Then it is immersed intohot-dip plating bath. With uniform layer, strong adhesion, coating won’tfall off after long-time use to ensure reliable corrosion resistance ofgalvanized steel pipe.

Apart from transporting low pressure fluid such as water, gas and oil, galvanized steel pipe is also used inoil industry, particularly oil well tubes of offshore oilfield, pipeline, oil heaters ofchemical coking equipment, condensing cooler, oil exchangetube of coal distillation ofwash, trestle piles and mine tunnel support frame tubes, etc.

As typical amphoteric metal, zinccoating of galvanized steel pipe has bluish-white appearance and standard electrodepotential is 0.76V. It is also soluble in acidand dissolved in alkali. Zinc is very stable in dry air and critical humidityis bigger than 70% for corrosion. So it can form a thin film, mainly composedof basic zinc carbonate, with carbon dioxide and oxygen in humid atmosphere. This thin film can slow the corrosion process. It canalso react with hydrogen sulfide and form zinc sulfide. In addition, zinc is not stable in seawater because it is vulnerable to chloride ion.

Standard potential of Zinc is smallerthan iron, so as an anode coating foriron and steel it can provide reliable electrochemical protection. Zinc layercan be chosen as protective measure in iron and steelproducts which are used in industrial atmosphere, rural atmosphere and oceanic atmosphere.And its service life is almost proportional toits thickness. When there is industrial exhaust pollution in atmosphere, zinclayer has better performance than cadmium coating.Whereas the opposite is true in seawater.

Application temperature of zinc layer of galvanized steel pipe shouldnot exceed 2500℃because zinc crystal tissue becomes deformed andbrittle, thus anti-corrosion ability decreases. It can form white loosecorrosion product called white frost, when it is in contact with volatilecompounds of non-metallic materials such as, low molecular weight carboxylicacids, aldehydes, phenols and ammonia in closed orventilation poor space or humid air. In addition, zinc has the tendency ofgrowing filamentous single crystal which is called long hair.

Detailed Specifications

Size (outer diameter X wall thickness): 13.7 - 168.3mmX 1.8-6mm

Standard: GB/T 3091 BS1387 ASTM A 53

Grade of steel: Q195/Q235B/Q345B

Length, lathe thread at both ends, pipe clamp and plastic capcan be customized according to the specific requirements of customers.

Links:https://www.globefindpro.com/products/87955.html