Piling Pipe

Piling Pipe

In recent years, piling pipe iswidely used in many fields and the diameter of this product is becoming largerand larger. According to the different needs of customers, we can providequality product and services. Strip coil is the raw material and warm extrusionand automatic double wire-sided submerged arc welding process are used tomanufacture this product. This product can be used as permanent load supportingtube for construction of bridges, roads, high-rise buildings and deepwater wharfs.

Detailed Specifications

Standard: ASTM A252

Grade of steel: Grade 1/Grade 2/ Grade 3

According to different manufacturing processes, piling pipe can be divided intoHFW type, SMLS type, LSAW type and SSAWtype.

(1) HFW Pipe (1-2)

Size (outer diameter× wall thickness): 33.4 - 609.6mmX 2.1 -14mm

Hot rolled steel is the raw material and technique is HFW

(2) SMLS Pipe (3-4)

Size (outer diameter× wall thickness): 13.7 - 609.4mmX 2.24-30.96mm

This product is manufacturedby tube perforation, cold rolling and cold drawing.

(3) LSAW Pipe (5-6)

Size (outer diameter× wall thickness): 325--1420mmX 6.0 - 18mm

JCOE forming, one weld and submerged arc welding process are used.

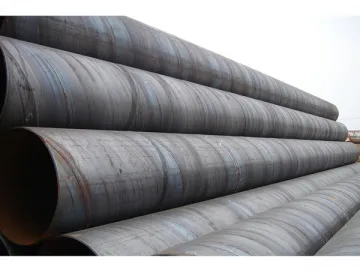

(4) SSAW Pipe (7-8)

Size (outer diameter× wall thickness): 219--2220mmX 6.0 - 18mm

HFW type is heated and welded with 10-500KHZhigh-frequency current. It has fast welding speed, small welding affected areaand high-quality weld. SMLS type has no seam. With big wall thickness andstrong pressure bearing ability, this product is a good choice for buildingpiling. The manufacturing process of LSAWtype is very flexible and many models with unique specification and wallthickness are available. Many of them are not available for the other threetypes. Low carbon structural steel or low alloy steel strip are turnedinto tube blank in molding angle to manufacture SSAW type piling pipe. Afterthat, seam of tube is welded together. Narrow strip steel can be used tomanufacture large diameter tube and the production process is simple, highlyefficient and cost effective.

Links:https://www.globefindpro.com/products/87958.html