UL1617 Insulated Wire

UL1617Insulated Wire

1

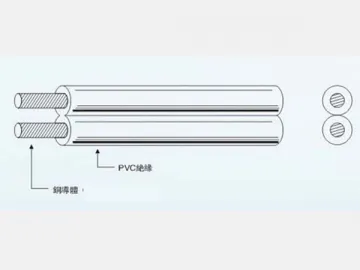

With resistance to acid, alkali and oil, damp proofing and mouldproofing, the UL 1617 insulated wire is constructed of 30-10AWG single orstranded bare or tinned copper conductor, lead-free PVC insulation and PVCjacket. The insulation layer has uniform thickness and is easy to peel and cutoff. Meeting thestandard of UL758, UL1581 and CSA C22.2 NO.210.2, this product works under therated temperature of 105℃and voltage of 600V. It has passed the UL VW-1and CSA FT1 vertical flame test, and can be replaced by UL 10937.

Structure

2

,:

Conductor

PVC PVC Insulation

PVC PVC Jacket

| Model | Conductor | Insulation thickness | Jacket thickness | Overall diameter | Standard length | Conductor resistance at 20℃ | |||

| AWG | Construction | British system | Metric system | Uncoated | Tinned | ||||

| NO./mm | mm | mm | mm | Ft/coil | M/coil | Ω/Km | Ω/Km | ||

| UL 1571 CSAT1(TR-64) | 30 | 7/0.102 | 0.79 | 0.41 | 2.70-0.10 | 2000 | 610 | 354 | 381 |

| 28 | 7/0.127 | 0.79 | 0.41 | 2.80-0.10 | 2000 | 610 | 223 | 239 | |

| 26 | 7/0.160 | 0.79 | 0.41 | 2.90-0.10 | 2000 | 610 | 230 | 150 | |

| 24 | 11/0.160 | 0.79 | 0.41 | 3.00-0.10 | 2000 | 610 | 87.6 | 94.2 | |

| 22 | 17/0.160 | 0.79 | 0.41 | 3.20-0.10 | 2000 | 610 | 55.4 | 59.4 | |

| 20 | 21/0.180 | 0.79 | 0.41 | 3.40-0.10 | 2000 | 610 | 34.6 | 36.7 | |

| 18 | 34/0.180 | 0.79 | 0.41 | 3.60-0.10 | 2000 | 610 | 21.8 | 23.2 | |

| 16 | 26/0.254 | 0.79 | 0.41 | 3.90-0.10 | 2000 | 610 | 13.7 | 14.6 | |

| 14 | 41/0.254 | 0.79 | 0.41 | 4.30-0.15 | 2000 | 610 | 8.62 | 8.96 | |

| 12 | 65/0.254 | 0.79 | 0.41 | 4.80-0.15 | 2000 | 610 | 5.43 | 5.64 | |

| 10 | 105/0.254 | 0.79 | 0.41 | 5.60-0.20 | 2000 | 610 | 3.409 | 3.546 | |

The UL 1617insulated wire produced by our company can be used for the inner connection ofelectrical and electronic equipment. Thickness of the insulation and the jacketis 0.79mm and 0.41mm, respectively. This product hasexcellent flame retardance,resistance to ageing and chemical corrosion, and high mechanical strength,which is a fine insulated product. The conductor resistance at 20℃ is 3.409to 354 Ω/Km for the untinned copper and is 3.546 to 381 Ω/Km for the tinned copper,making the product an ideal choice for customers.

Links:https://www.globefindpro.com/products/88092.html