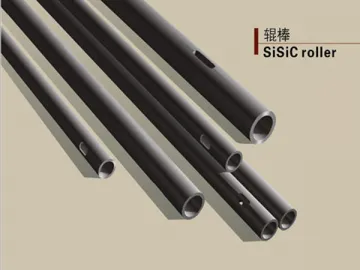

Silicon Carbide Roller

Silicon Carbide Roller

Silicon carbide roller has high strength and oxidation resistance. It is anideal fire-endurance component used in the clinkering zone of roller kiln. Ithas a lifespan 10 to 15 times of aluminum oxide ceramic roller due to its largebearing capacity under high temperature.

Bearing Capacity

| Section size | Wall thickness (mm) | Concentrated force (kg.m /L) | Uniformly distributed force (kg.m /L) |

| 30 | 5 | 43 | 86 |

| 35 | 5 | 63 | 126 |

| 38 | 5 | 77 | 154 |

| 40 | 6 | 97 | 194 |

| 45 | 6 | 130 | 260 |

| 50 | 6 | 167 | 334 |

| 60 | 7 | 283 | 566 |

| 70 | 7 | 405 | 810 |

Note:

The bending strength is calculated according to 250MP and 5 times of safetycoefficient. The bearing capacity is calculated as 1 meter length. If theproduct length is L, the bearing capacity can be calculated by that: concentrated force = value intable x 1/L; uniformly distributed force =value in table x 1/L. The applied temperature is 1380 ℃.

Dimension

Roller is one of the major components of kiln andfurnace. Our product is a hollow cylinder made from reaction-sintered siliconcarbide. Its perfect straightness ensures the delivery smoothness andstability. The silicon carbide remains its high strength under hightemperature, preventing deformation or fracture. We offer different sizes ofsilicon carbide rollers with section radius from 30 to 70 mm and wall thickness from 5 to 7 mm. Product with larger size has a largerbearing capacity.

Links:https://www.globefindpro.com/products/88399.html

-

HVN Vane Motor

HVN Vane Motor

-

Silicon Carbide Ceramic Thermal Pipe

Silicon Carbide Ceramic Thermal Pipe

-

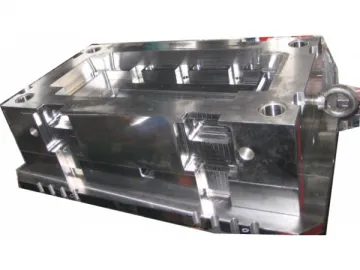

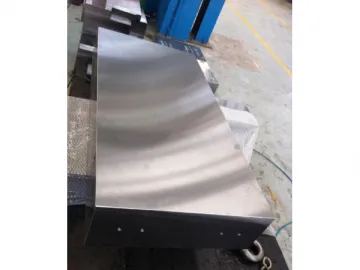

Mould Cavity

Mould Cavity

-

Desulfurization Dust Spray Nozzle

Desulfurization Dust Spray Nozzle

-

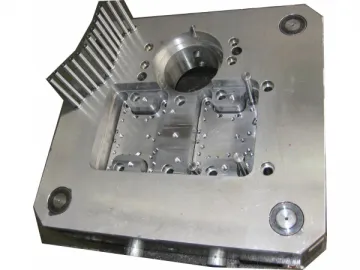

Mould Core

Mould Core

-

Pallet Mould

Pallet Mould

-

3D Crystal Subsurface Laser Engraving Machine

3D Crystal Subsurface Laser Engraving Machine

-

Moulds for Electronic Components, Double Injection Mould

Moulds for Electronic Components, Double Injection Mould

-

3D Crystal Glass Laser Engraving Machine

3D Crystal Glass Laser Engraving Machine

-

LJ380/NAK80 Plastic Mold Steel

LJ380/NAK80 Plastic Mold Steel

-

Silicon Carbide Sandblasting Nozzle

Silicon Carbide Sandblasting Nozzle

-

Silicon Carbide Ceramic Bushing

Silicon Carbide Ceramic Bushing