Six in One Non-Woven Bag Making Machine

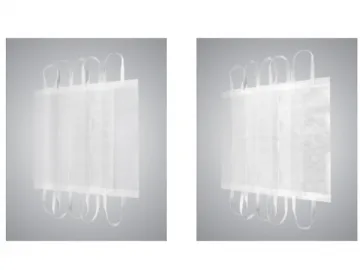

Six in One Non-Woven Bag Making MachineThe ZW-FB600D six in one non-woven bag making machine is capable of manufacturing non-woven bags of different sizes in different shapes, such as the carrier bag with hand-held strap provided, non-woven zipper bag, square bottom bag, vest bag, flat bag and bottom gusset bag. The multi-functional machine carries the functions and value of several machines, thus greatly increasing the efficiency and saving the investment cost of the customers. Our machine has nowadays become the latest generation home and abroad and the favorable choice for all the customers.

Main Technical Parameters of the Six in One Non-Woven Bag Making Machine

Type | ZW-FB600D | Total Power (kw) | 15kw |

Power Supply | 380V/220V | Total Weight | 3000kg |

Applicable Material | Non-woven and PP, PE | Overall Dimension (L*W*H) | 9600*1800*1800mm |

Material Thickness | 30-100g | Max. Bag-making Width | 850mm |

Max. Bag-making Length | 580mm | Production Speed | 30-100pcs, depending on the size and shape of the bag |

With an overall dimension of 9600*1800*1800mm and the total weight of 3000kg, the total power of the ZW-FB600D six in one non-woven bag making machine can reach 15kw. The whole process is micro-computer controlled, and material feeding, punching, and zippering are all conducted automatically under the operation of only one technician, thus increasing the production capacity greatly. Moreover, the machine is equipped with anticipate alarm device. In case of no material feeding during the operation, the alarm will sound and the machine will be shut down promptly to avoid unnecessary loss.

The ZW-FB600D six in one non-woven bag making machine is also characterized with its simple operation, fast bag-making speed and advanced welding technique. It is simple and easy to operate the whole machine. It is also convenient to change functions and then make bags of various designs. The bag making speed is comparatively fast with flat bag 30-100 pcs/m, square bottom bag 30-60 pcs/m, zipper bag 30-70 pcs/m, carrier bag 30-40 pcs/m, vest bag 30-80 pcs/m and bottom gusset bag 30-100 pcs/m. Since high-performance ultrasonic welding technique is adopted, there is lower noise at welding part and it causes no harm to operators.

Links:https://www.globefindpro.com/products/88550.html

-

Laser Die Cutting Machine

Laser Die Cutting Machine

-

Automatic Plastic Carrier Bag Making Machine with Heat Sealing and Cutting

Automatic Plastic Carrier Bag Making Machine with Heat Sealing and Cutting

-

CNC Router, XY-2

CNC Router, XY-2

-

Automatic Double Layer Plastic Bag Making Machine

Automatic Double Layer Plastic Bag Making Machine

-

Non-Woven Bag Making Machine with Handle Cutting

Non-Woven Bag Making Machine with Handle Cutting

-

CNC Router, XY-4

CNC Router, XY-4

-

Double Handle Non-Woven Bag Making Machine

Double Handle Non-Woven Bag Making Machine

-

Automatic Plastic Winding Machine

Automatic Plastic Winding Machine

-

Four Color Flexographic Printer

Four Color Flexographic Printer

-

Plasma Cutting Machine

Plasma Cutting Machine

-

Non-Woven Zipper Bag Making Machine

Non-Woven Zipper Bag Making Machine

-

Side Mount Roller Door Opener Motor

Side Mount Roller Door Opener Motor