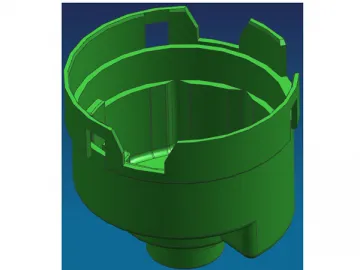

Plastic Cup Mold

Plastic Cup Mold

Our plastic cup mold can be used to make oneplastic cup in one tooling. It adopts PS as the raw material because of itsnon-poisonousness,clearness and cheap price. The material is now widely used as a replacement ofexpensive resin to create products with big volume, such as our plastic cup. In addition, this mold isavailable with the hot runner system, which can greatly save plasticconsumption and ensure beautiful appearance of the final product.

ProductInformation

| Project Name | Cup |

| Number of Parts | 1 part in 1 tooling |

| Material | PS |

| Product Size | 81.3*56.2*52.2 |

| Exported Country/Customer | South Africa |

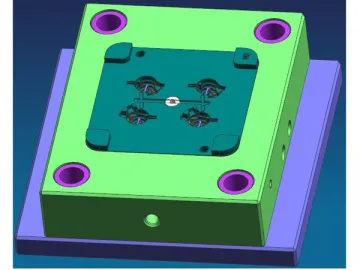

Mold Details

| Cavity No. | 1 | Plastic | PS | Moulding Machine | 100 T Sumitomo |

| Core Cavity Material | S136 | Mold Life Warranty | 500K | Mould Type | 3 plate |

| Mould Size | 300*250*361 | Mold Base | S50C | Mold Features | DME std |

| Mould Weight | 157 KG | Runner | Hot Runner ( YODO ) | Gate Type | Hot sprue |

Advantages of Hot Runner System

1. Our plastic cup mold is equipped withthe hot runner system, so that PS material can be fully used in the production of plastic cup without any loss at all the time,and defect or trouble due to the entering of foreign material can beeffectively prevented.

2. The hot runnersystem allows the new resin to be always melted up to gate, so that thematerial just needs to fill up the cavity of the plastic cup mold. This alsohelps to shorten the time of injection, measurement, cooling and mold openingor closing as well as the time to take out sprue and runner.

3. It helpsimprove the product quality. The problems caused by shrinkage, weld, andinternal stress can be solved, as the injection pressure of injection mold is directly transferred to cavity

4. The mechanicalefficiency of our plastic cup mold is increased because injection quantity,injection pressure, mold opening distance, and sprue and runner amount are all decreased.

5. Through theuse of the hot runner system, pressure exerted on the mold is reduced due todecrease of injection pressure and 3-stage mold of large type may be convertedinto 2-stage mold. This helps prevent the trouble caused by 3-stage mold, so asto extend the service life of the plastic cup mold.

Links:https://www.globefindpro.com/products/88740.html

-

Plastic Carrier Mold

Plastic Carrier Mold

-

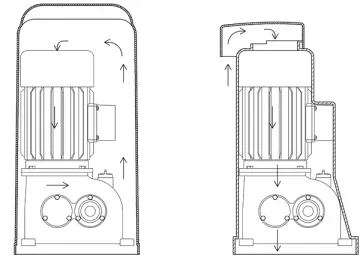

Silent Hydraulic Pile Driving Machine

Silent Hydraulic Pile Driving Machine

-

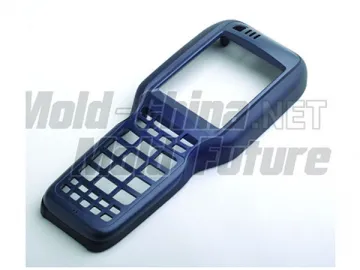

Handhold POS Mold

Handhold POS Mold

-

Hydraulic Vibratory Hammer

Hydraulic Vibratory Hammer

-

Plastic Case Mold

Plastic Case Mold

-

POM Injection Mold

POM Injection Mold

-

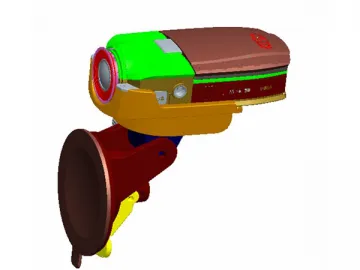

Car Video Recorder Mold

Car Video Recorder Mold

-

Paddlewheel Aerator Spare Parts

Paddlewheel Aerator Spare Parts

-

Fiber Cement Wall Corner (Pre-Manufactured Mitered Corners)

Fiber Cement Wall Corner (Pre-Manufactured Mitered Corners)

-

Splash Aerator

Splash Aerator

-

Diesel Drive Multi Impeller Paddlewheel Aerator

Diesel Drive Multi Impeller Paddlewheel Aerator

-

Multipurpose Crawler Piling Machine

Multipurpose Crawler Piling Machine